Compsn. of releasing heat after contacting air

A compound and heat release technology, applied in the field of heat release compound, can solve the problems of short heat release time, large temperature fluctuation, concentrated heat release, etc., and achieve the effect of fast heat release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

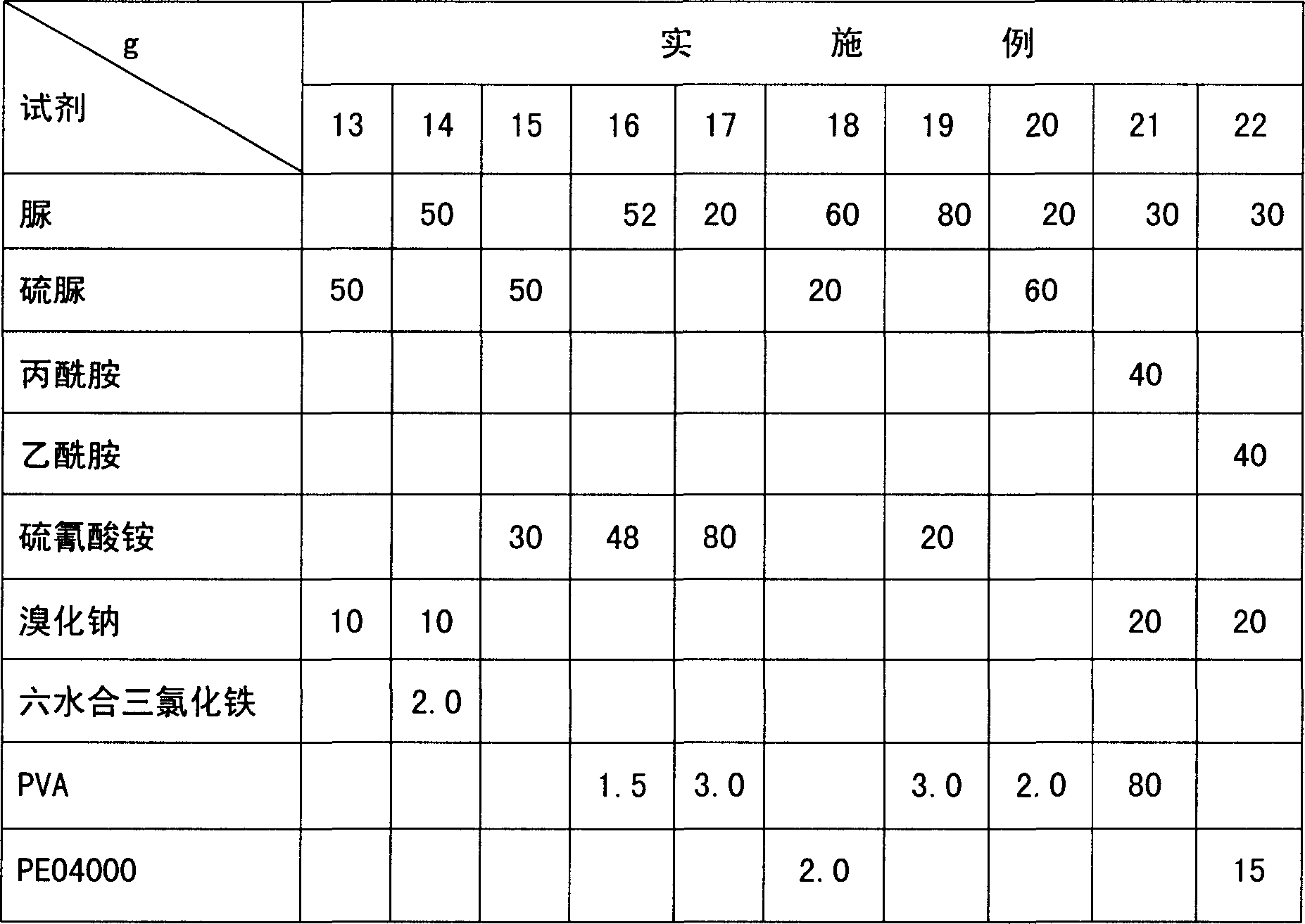

Examples

Embodiment 1

[0028] Reagents: Zinc powder 50g, activated carbon 15g, ionic liquid [BMIM][BF 4 ] (chemical name is 1-methyl-3-butylimidazolium tetrafluoroborate) appropriate amount.

[0029] Mix zinc powder and activated carbon evenly, add ionic liquid and stir to make a wet paste to obtain a heat-generating compound, wrap the compound with nylon silk cloth, put a thermometer in the center, and observe the temperature change. Results: The temperature rose rapidly to 180°C and lasted for more than 30 minutes.

Embodiment 2

[0031] Reagents: urea 30g, acetamide 40g, sodium bromide 20g, zinc powder 50g, activated carbon 15g.

[0032] Weigh urea and acetamide sodium bromide according to the amount, mix and heat to melt to obtain low-temperature eutectic salt. Mix activated carbon and zinc powder in equal volumes, add the above-mentioned low-temperature eutectic salt, stir to form a wet paste to obtain a heat-generating compound, wrap the compound with nylon silk cloth, put a thermometer in the center, and observe the temperature change. Results: The temperature rose rapidly to 150°C and lasted for more than 30 minutes.

Embodiment 3

[0034] Reagents: urea 30g, propionamide 40g, sodium bromide 20g, zinc powder 50g, activated carbon 15g.

[0035] Weigh urea and propionamide sodium bromide according to the amount, mix them and stir in a container to obtain a room temperature ionic liquid (room temperature eutectic salt). Mix activated carbon and zinc powder, add the above-mentioned ionic liquid at room temperature, stir to form a wet paste to obtain a heat-generating compound, wrap the compound with nylon silk cloth, put a thermometer in the center, and observe the temperature change. Results: The temperature rose rapidly to 150°C and lasted for more than 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com