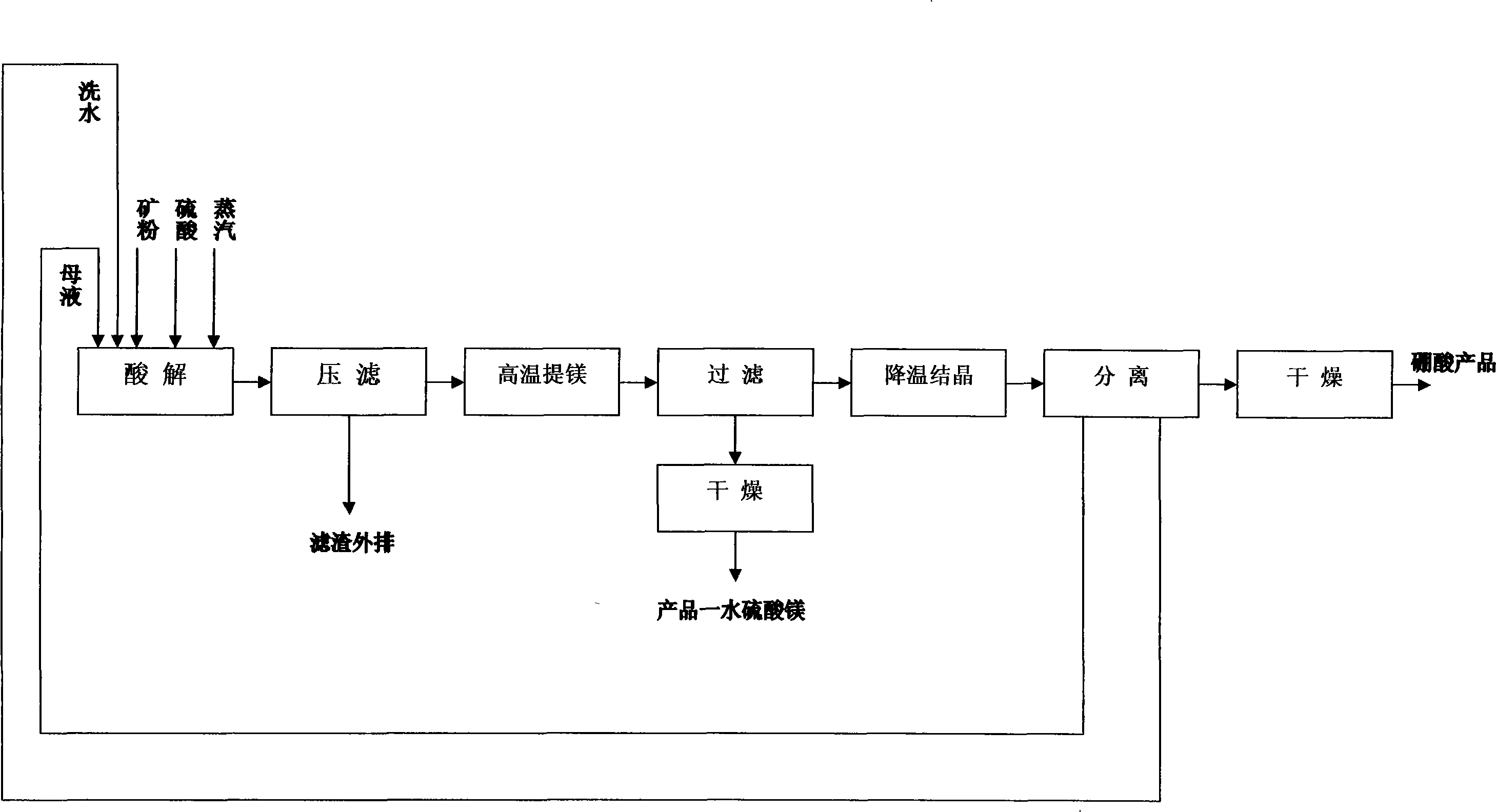

Technology for producing boracic acid and monohydrate magnesium sulfate by employing ascharite ore sulfuric acid process

A technology of magnesium sulfate and sulfuric acid method, applied in the direction of magnesium sulfate, boron oxide, etc., can solve the problems of waste of boric acid and magnesium sulfate resources, large equipment investment, low energy consumption, etc., achieve obvious energy saving effect, reduce sulfuric acid consumption, improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 20 kilograms of boric acid mother liquor, 4 kilograms of washing water, sample and test MgSO after mixing 4 ·7H 2 oContent 18.32%, H 3 BO 3 Content 2.83%. Weigh 40 mesh 6 kg of boron-magnesium ore powder produced in Tibet, sample and test for MgO content of 17.38%, CaO content of 6.42%, B 2 O 3 Content 32.06%. Weigh 2.4 kg of industrial grade 93% sulfuric acid.

[0017] Pour 24 kg of the mixed mother liquor washing water into the acidolysis tank, heat it to about 40 ° C, start stirring, slowly add sulfuric acid and mineral powder, and continue to heat, and be careful not to overflow the pot during operation. Until the sulfuric acid and mineral powder are added, the temperature is raised to 95°C for reaction for 2 hours, then filtered, the filter residue is discarded, the acid hydrolyzed solution is poured into the magnesium extractor while it is still hot, and the machine port is closed. Heating and raising the temperature to 180°C under stirring conditions...

Embodiment 2

[0019] Weigh 44 kilograms of boric acid mother liquor, 6 kilograms of washing water, sample and test MgSO after mixing 4 ·7H 2 O content 17.36%, H 3 BO 3 Content 2.85%. Weigh 40 mesh and 14 kg of boron-magnesium ore powder produced in Tibet, take samples and test for MgO content of 17.38%, CaO content of 6.42%, B 2 O 3 Content 32.06%. Weigh 5.3 kg of industrial grade 93% sulfuric acid.

[0020] A total of 50 kg of the mixed mother liquor washing water was poured into the acidolysis tank, heated to about 40 ° C, started to stir, slowly added sulfuric acid and mineral powder and continued to heat. The temperature was raised to 95°C and reacted for 2 hours, then filtered, the filter residue was discarded, the acid hydrolyzed solution was poured into the magnesium extractor while hot, the machine port was closed, the temperature was raised to 170°C under stirring conditions, the constant temperature was maintained for 7 hours, and the pressure was discharged. Immediately fi...

Embodiment 3

[0022] Weigh 42 kilograms of boric acid mother liquor, 8 kilograms of washing water, sample and test MgSO after mixing 4 ·7H 2 O content 14.16%, H 3 BO 3 Content 2.72%. Weigh 20 kilograms of boron-magnesium ore powder produced in Qinghai Chaidan, sample and test the MgO content of 16.22%, B 2 O 3 The content is 15.68%, and the amount of CaO is negligible. Weigh 5.8 kg of industrial grade 93% sulfuric acid.

[0023] Pour 50 kg of the mixed mother liquor washing water into the acidification tank and heat to about 40°C. Gradually add sulfuric acid and mineral powder under stirring and continue to heat until the mineral powder and sulfuric acid are added. The temperature was raised to 95°C for 1.5 hours. Then filter, discard the filter residue, put the acid hydrolyzed solution into the magnesium extractor while it is still hot, close the machine port, start stirring, slowly heat up to 190°C, keep the temperature constant for 6 hours, discharge the steam to release the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com