Discharge lamp

A technology for discharge lamps and electrodes, applied in discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve the problems of heat transfer body leakage, easy to become high temperature and welding, cracks (cracks, etc.), to prevent damage, high durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

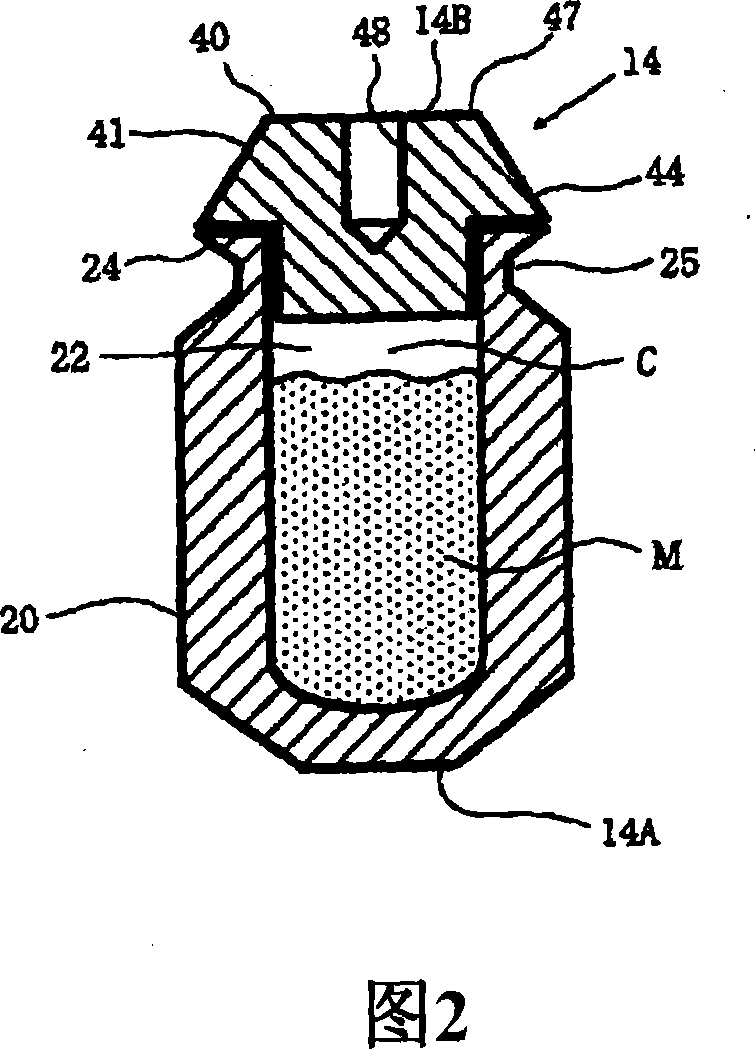

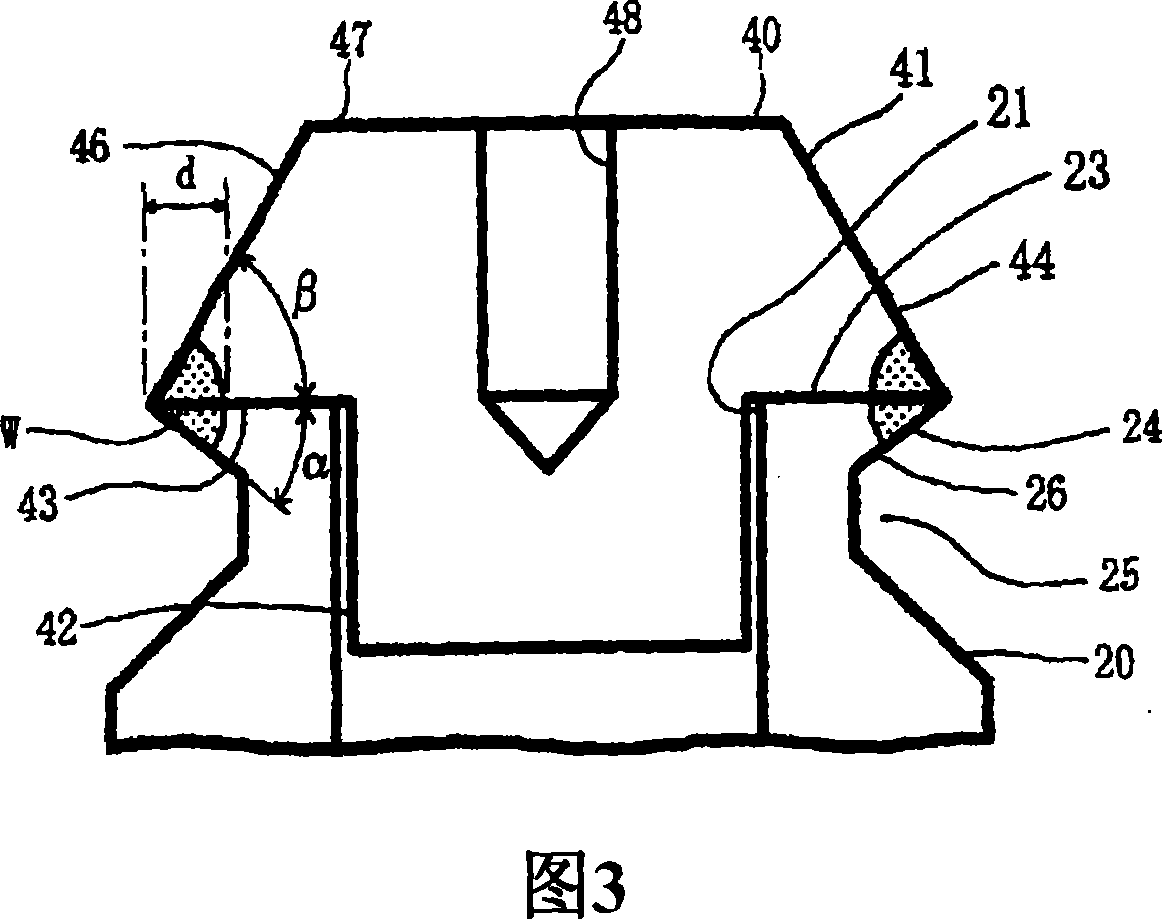

[0079] The cylindrical outer diameter of the base part produced by cutting is 29 mm, the height of the base part is 60 mm, the outer diameter of the flange part on the base part side is 27 mm, the width of the flat surface on the base part side is 4 mm, and the apex angle of the flange part on the base part side is The angle α is 60°, the outer diameter of the flange on the cover side is 27 mm, the width of the flat surface on the cover side is 3.8 mm, and the angle β of the flange on the cover side is 60°. The base part and the cover part were welded, silver was sealed in the closed space as the heat transfer body M, and the radial width d of the ring-shaped welded part was manufactured under the different welding conditions shown in Table 1. Each electrode.

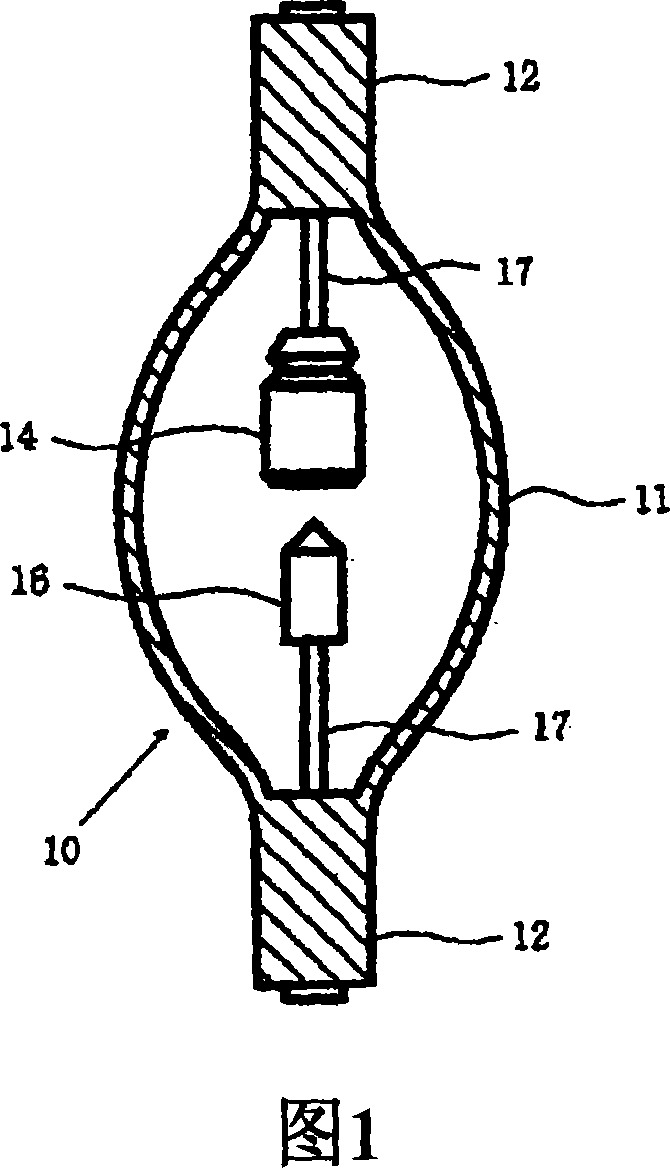

[0080] Next, make the internal volume of the luminous tube part 850cm 3 The luminous tube is assembled using each of the electrodes made above to make a 50mg / cm 3 Mercury as the luminous substance in discharge lamps. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com