Fabricated culvert member and construction method thereof

A prefabricated and culvert technology, which is applied in the direction of buildings and road bottoms, can solve the problems of ineffective use of area, evaporation, large infiltration, human, financial, and material, and improve the water utilization coefficient of the canal system , no pollution, little impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

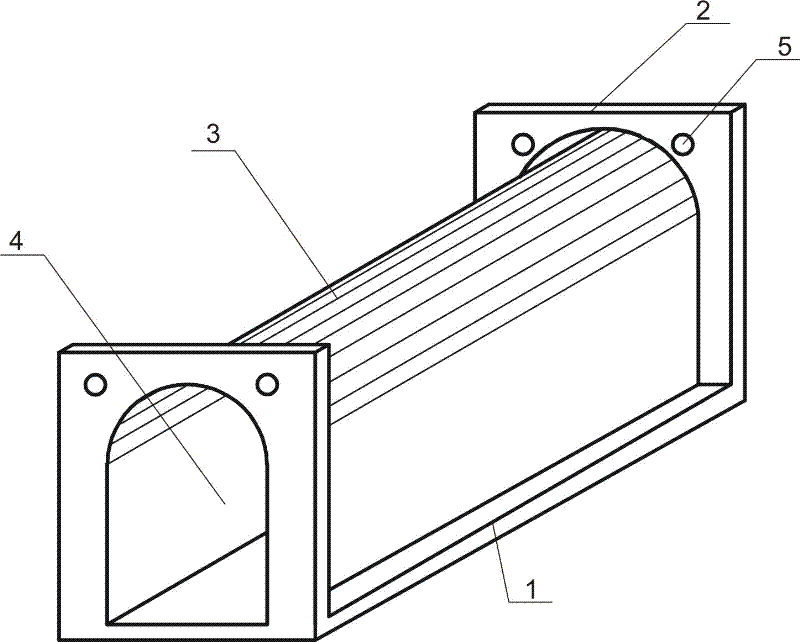

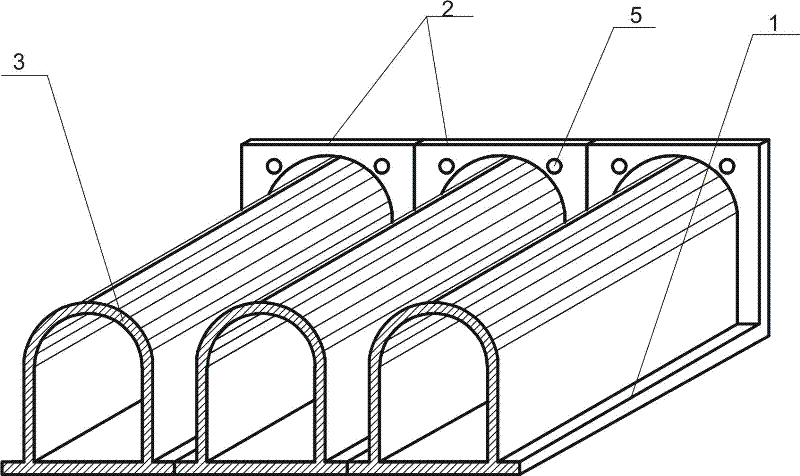

[0029] Example 1: as figure 1 As shown, a prefabricated culvert member includes a bottom plate 1 , a rib plate 2 and an arc-shaped plate 3 . The rib plate 2 is in the shape of a door and is fixed on both ends of the arc plate 3. The lower ends of the arc plate 3 and the rib plate 2 are fixed on the bottom plate 1, and the three are integrated. The space between the arc plate 3 and the bottom plate 1 Both are drains 4. In order to facilitate quick installation of the component and maintenance of the component, two hoisting holes 5 are provided above the rib plate 2 . In order to facilitate the smoother water flow in the channel and increase the water flow section, the present invention can also assemble multiple groups of culvert components in parallel (such as figure 2 ). like Figure 7 The specific installation and construction methods of the culvert components are as follows: Design and process culvert components: design culvert components for standby according to th...

Embodiment 2

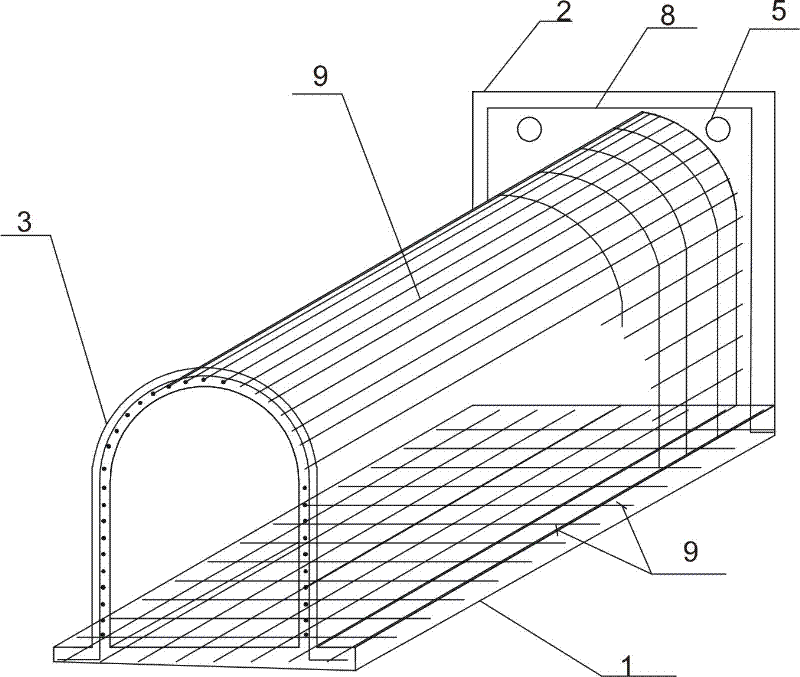

[0030] Example 2: as image 3 Shown: The culvert member is mainly based on the embodiment 1. On the base plate 1 and the rib plate 2, steel mesh or wire mesh 9 for improving the mechanical strength and crack resistance of the culvert member is added. A hoisting steel bar 8 is embedded on the top edge, and the lower end of the steel bar 8 is fixedly connected with the steel wire mesh or barbed wire mesh in the bottom plate 1 . According to the channel width, depth, water flow and other factors, determine the buried depth, thickness, appearance size, wire diameter (usually No. 12 iron wire), wire mesh hole size (usually 3 cm square aperture), and hoisting rib steel bar diameter ( Generally, it is a hot calendered round tertiary steel bar with a diameter of 12-16 mm). Conventional culvert component size: the thickness of the arc plate is 4-15 cm, the length is 1-3 meters, the bottom width of the section is 0.6-2 meters, and the reinforcement meets the design requirements. Its i...

Embodiment 3

[0031] Example 3: as Figure 4 As shown, in the road or the drainage ditch on both sides of the road, the culvert member is made to have multiple drainage holes 6 on the basis of implementation 2, and the drainage holes 6 are preferably about 0.5-1 cm in diameter Plum-shaped distribution, which facilitates the removal of residual water in the soil. The installation and implementation method thereof is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com