Inertia-stage blades of a water delivery tank with a coating for an air intake filter

A water conveying trough and coating technology, which is applied in the field of inertial blades, can solve the problems of increasing difficulty in capturing and conveying, and achieve the effects of improving water conveying capacity, low cost and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings:

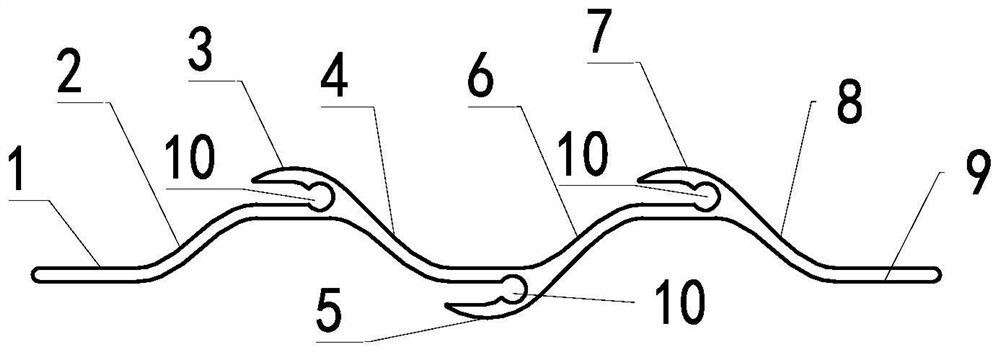

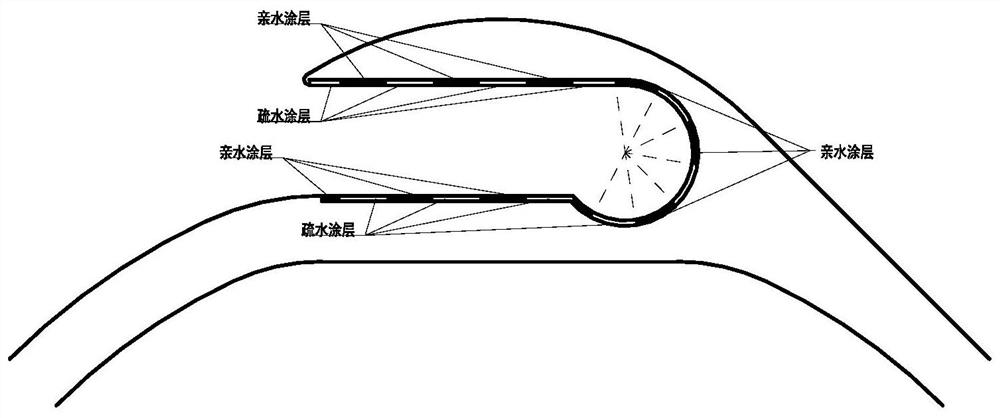

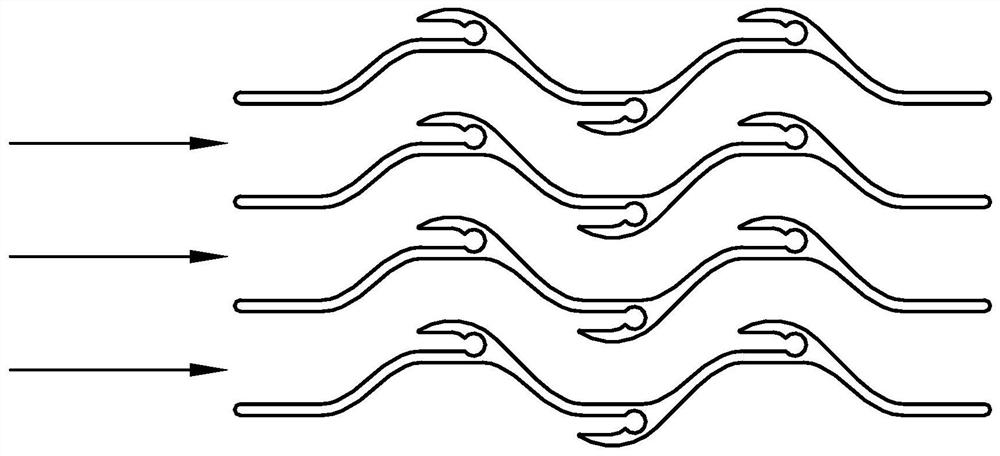

[0022] combine Figure 1a-3 ,like Figure 1a , 1b As shown, the cross section of the present invention is M-shaped and consists of three water conveying units, wherein the first water conveying unit is composed of a diversion section 1, a water conveying tank 3, two transition sections 2 and 4, and the second water conveying unit is composed of It is composed of water conveying tank 5, transition sections 4 and 6, and the third water conveying unit is composed of water conveying tank 7, transition sections 6, 8 and diversion section 9. The first and second water delivery units share the transition section 4, the second and third water delivery units share the transition section 6, the first and second water delivery units are arranged in mirror images, and the first and third water delivery units are arranged in the same direction. The inside of each water con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com