Preparation method of nylon 66/tackified polyester composite sheath core fiber

A sheath-core fiber and nylon technology is applied in the field of preparation of nylon 66/tackified polyester composite sheath-core fibers, which can solve the problem of high cost of production materials, and achieve the effects of improving service life, high resilience and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

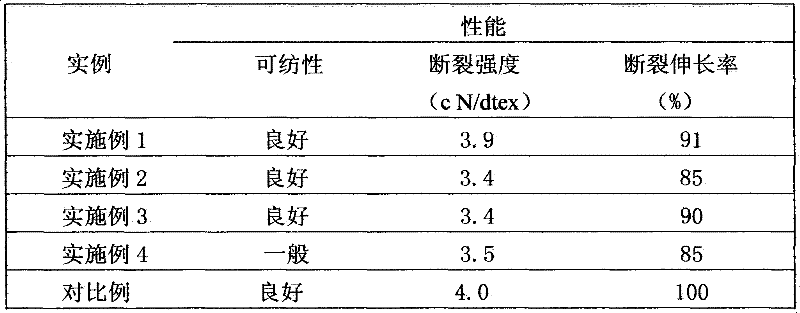

Embodiment 1

[0020] Nylon 66 with relative viscosity 2.7 and intrinsic viscosity 1.0 tackified polyester, with 70% (weight) nylon 66 and 30% (weight) tackified polyester, sheath-core composite, melt spinning, spinning temperature is 300 ℃ , the spinning pressure is 30.0MPa, the cooling air temperature and rheumatism wind speed is 18℃, 85%, 1.2m / s, the spinning speed is 500m / min, the oil bath drafting ratio is 3.8, 90~120℃ steam drafting, steam drafting The draw ratio was 1.1, resulting in a finished fiber of 33 dtex.

Embodiment 2

[0022] With relative viscosity 2.7 nylon 66 and intrinsic viscosity 0.7 tackifying polyester, with the nylon 66 of 70% (weight) and the tackifying polyester of 30% (weight), sheath-core composite, melt spinning, other process conditions are the same as embodiment 1, so as to get the finished fiber of 33dtex.

Embodiment 3

[0024] With relative viscosity 2.7 nylon 66 and intrinsic viscosity 1.0 tackifying polyester, with the nylon 66 of 50% (weight) and the tackifying polyester of 50% (weight), sheath-core composite, melt spinning, other process conditions are the same as embodiment 1, so as to get the finished fiber of 33dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com