Zinc-aluminium embedding co-penetrating method for iron and steel products and its penetrant

A product and iron and steel technology, which is applied in the field of zinc-aluminum inclusion co-infiltration method and infiltration agent for iron and steel products, can solve problems affecting the installation and use of equipment or parts, deformation of steel products, etc., and achieve production cost reduction, energy consumption reduction, The effect of excellent corrosion resistance and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

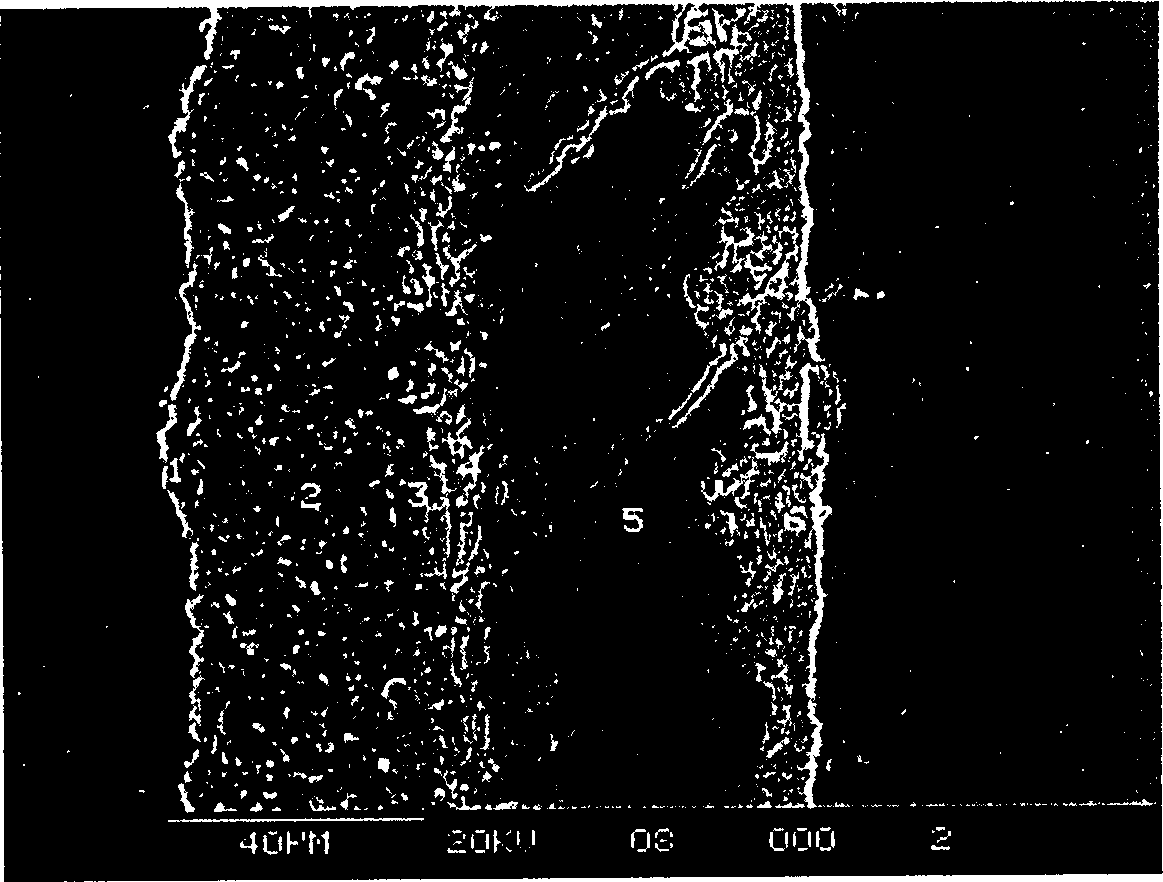

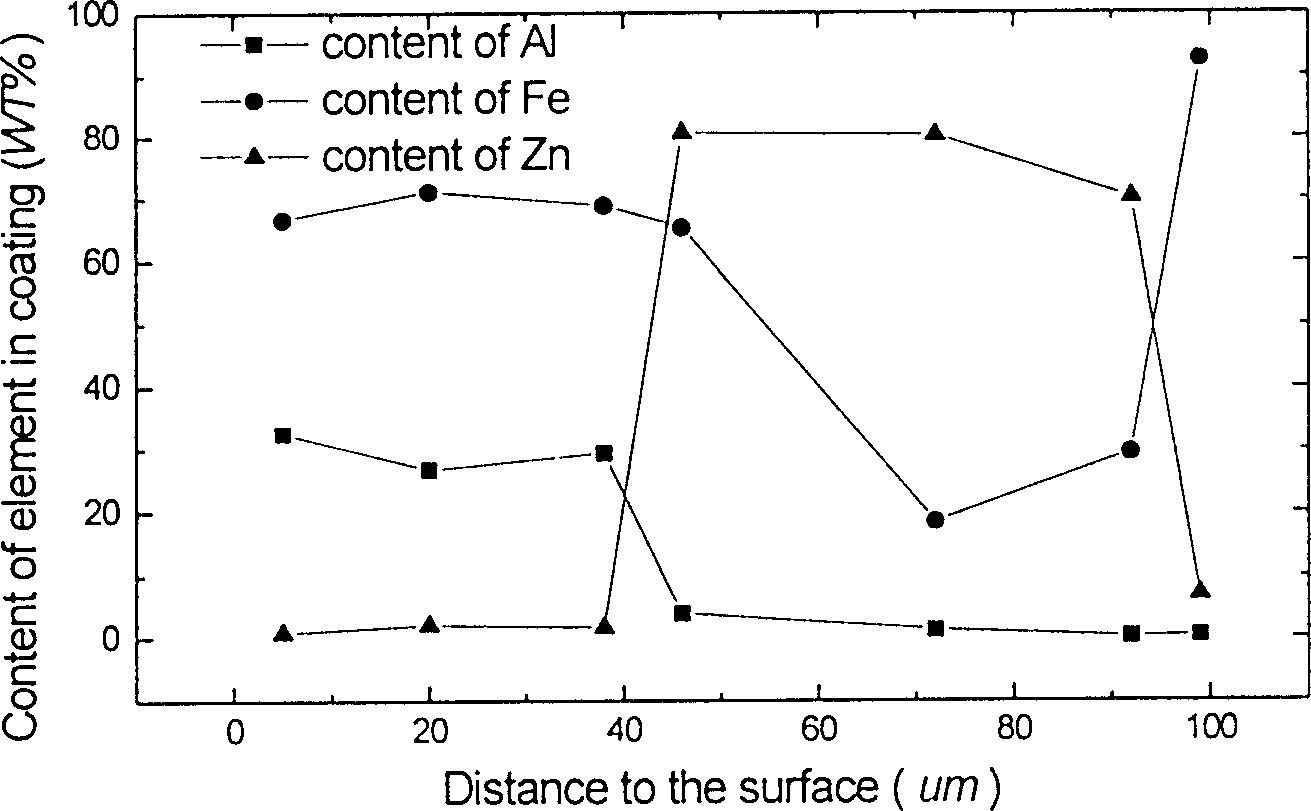

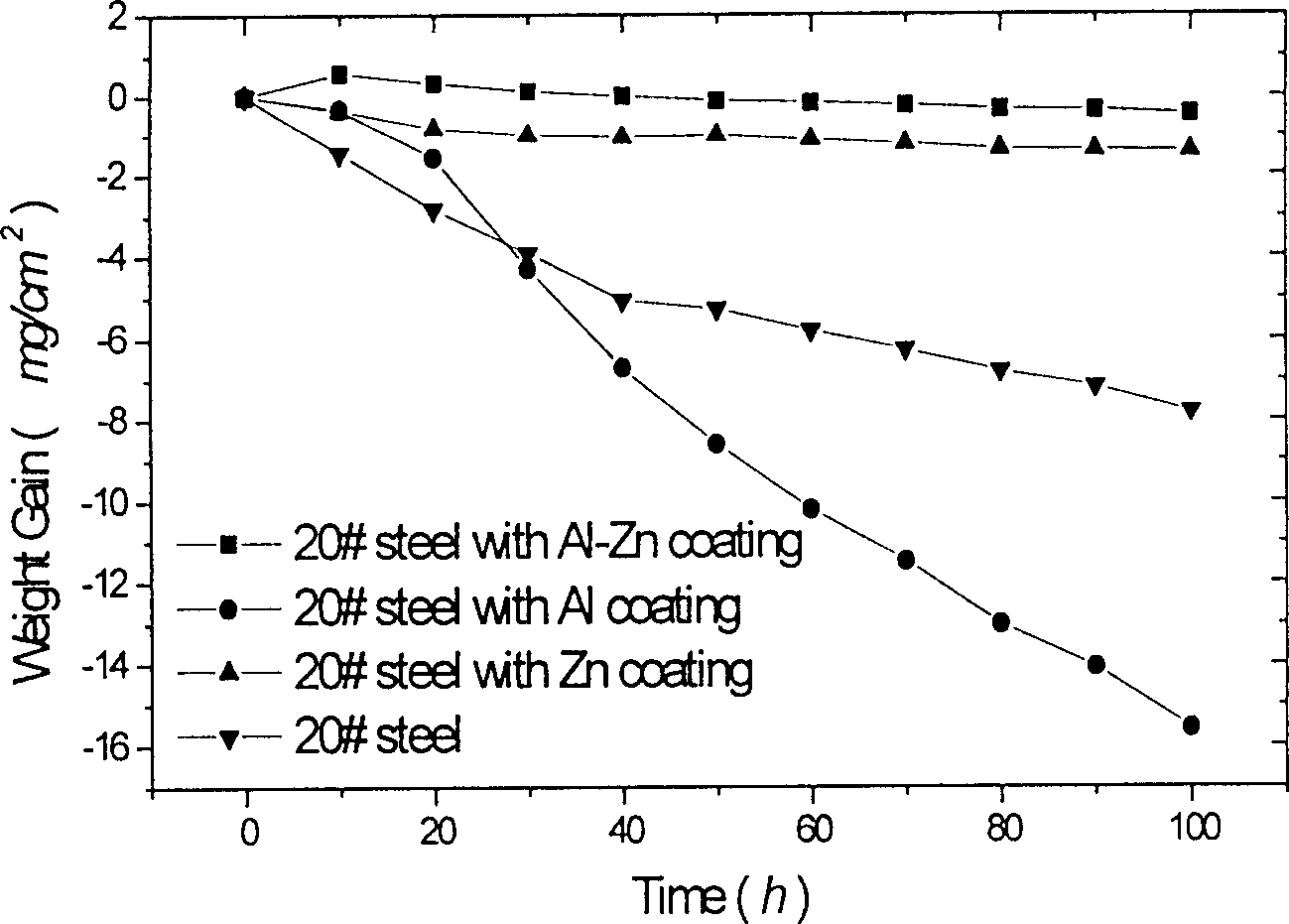

[0021] Example: Embed the iron and steel products in the infiltrating agent, at 400°C or 500°C or 600°C, after heat preservation treatment for 3 hours, 5 hours or 10 hours, an outer layer rich in aluminum and an inner layer are formed on the surface of the steel product. Zinc-aluminum co-dripping layer with zinc-rich double-layer structure.

[0022] After the zinc-aluminum coating is completed, the temperature is lowered to room temperature, the iron and steel product is taken out from the infiltration agent, and the residue on the surface is removed to obtain the steel product with the zinc-aluminum coating.

[0023] Before embedding steel products in penetrating agent, it is better to carry out surface degreasing or / and derusting or / and sandblasting of steel products; According to the condition, choose any one or any two or more treatment methods among oil removal, rust removal and sandblasting treatment.

[0024] In the above-mentioned embodiment, one of the penetrating ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com