Process for preparing synthetic methanol catalyst

A technology for synthesizing methanol and catalysts, which can be used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of short life, poor thermal stability, and many by-products. , to achieve the effect of easy operation control, large specific surface area, and product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

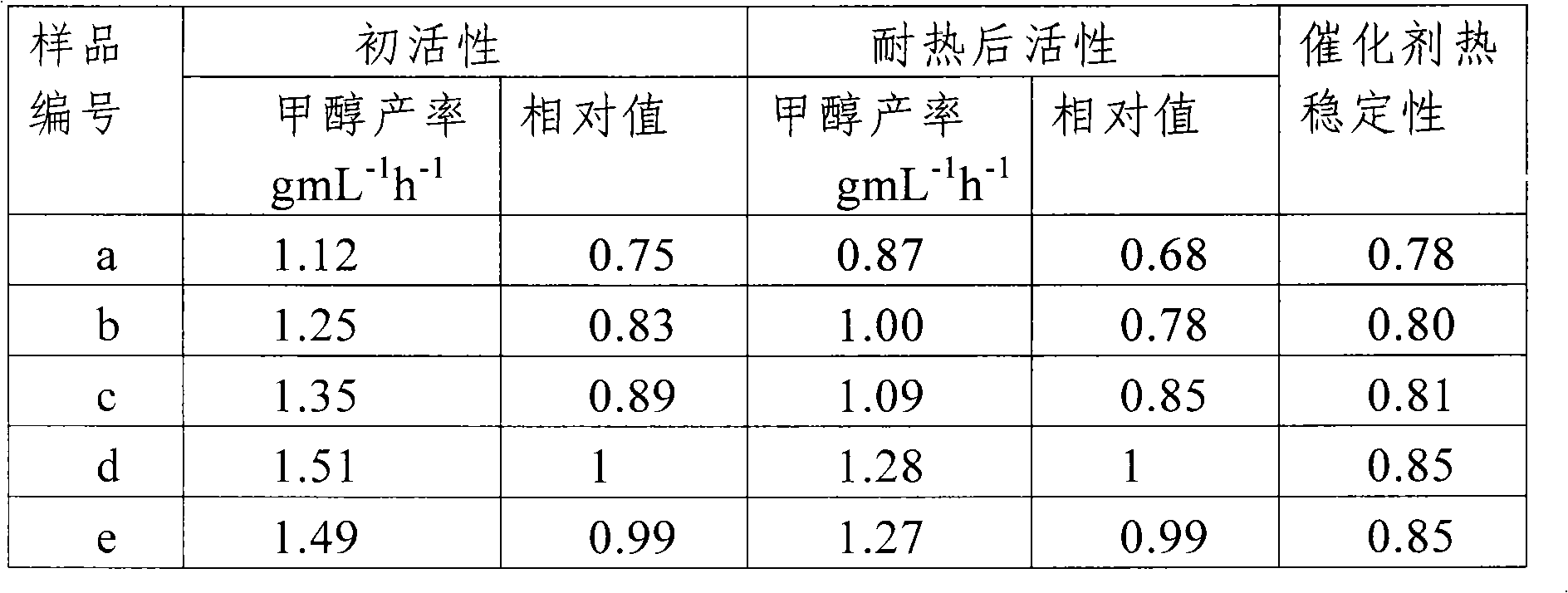

Examples

Embodiment 1

[0023] Weigh 182gCu(NO 3 ) 2 ·3H 2 O and 75gZn(NO 3 ) 2 ·6H 2 O was dissolved in 850mL deionized water to make solution A, heated to 60-85°C; weigh 106gNa 2 CO 3 Dissolve in 1000mL deionized water to make solution B, heat to 60-85°C; under stirring conditions, add solution A to solution B, control the end point pH to 7.0-7.5, continue stirring for 30 minutes, the color of the precipitate changes from blue to It is blue-green, keep the precipitation temperature at 60-85°C, let it stand for 2-3 hours, add 10g of Al to the prepared slurry 2 o 3 , and then filtered and washed to Na + content of ≤0.035% (w / w), the obtained filter cake is dried at 100-120 ° C, and then roasted at 320 ° C for 4 hours, and the roasted material is added with an appropriate amount of graphite and water and pressed into a tablet, which is a synthetic methanol catalyst sample. The sample number is a.

Embodiment 2

[0025] Weigh 182gCu(NO 3 ) 2 ·3H 2 O, 75gZn(NO 3 ) 2 ·6H 2 O and 75gAl(NO 3 ) 3 9H 2 O was dissolved in 850mL deionized water to prepare solution A, heated to 60-85°C; weighed 128gNa 2 CO 3 Dissolve in 1000mL deionized water to make solution B, heat to 60-85°C; under stirring conditions, add solution A to solution B, control the end point pH to 7.0-7.5, continue stirring for 30 minutes, the color of the precipitate changes from blue to It is blue-green. Keep the precipitation temperature at 60-85°C and let it stand for 2-3 hours. The prepared slurry is filtered and washed to Na + content of ≤0.035% (w / w), the obtained filter cake is dried at 100-120°C, and then roasted at 320°C for 4 hours, and the calcined material is added with appropriate amount of graphite and water, and pressed into tablets, which is the catalyst for methanol synthesis sample. The sample number is b.

Embodiment 3

[0027] Weigh 121gCu(NO 3 ) 2 ·3H 2 O and 75gZn(NO 3 ) 2 ·6H 2 O was dissolved in 850mL deionized water to make solution A, heated to 60-85°C; weighed 60g Cu(NO 3 ) 2 ·3H 2 O and 75gAl(NO 3 ) 3 9H 2 O was dissolved in 400mL deionized water to make solution B, and heated to 60-85°C. Weigh 128gNa 2 CO 3 Dissolve in 1200mL deionized water to make solution C, heat to 60-85°C; divide solution C into two parts C1 and C2, solution C1 is 800mL, and solution C2 is 400mL. Under the condition of stirring, add solution A to solution C1, control the end point pH to 7.0-7.5, continue stirring for 30 minutes, the color of the precipitate changes from blue to blue-green, and keep the precipitation temperature at 60-85°C to obtain slurry D; Add solution B to solution C2, control the end point pH to 7.0-7.5, and keep the precipitation temperature at 60-85°C to obtain slurry E. Then mix and stir the slurry D and E, and let it stand for 2 to 3 hours. The prepared mixed slurry is filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com