Methanol to aromatic catalyst containing two molecular sieves and preparation method

A molecular sieve and catalyst technology, applied in the field of methanol-to-aromatic catalyst and preparation, can solve the problems of loss of active components, influence on the yield of BTX light aromatics, and reduce the economy of methanol-to-aromatics, etc., and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

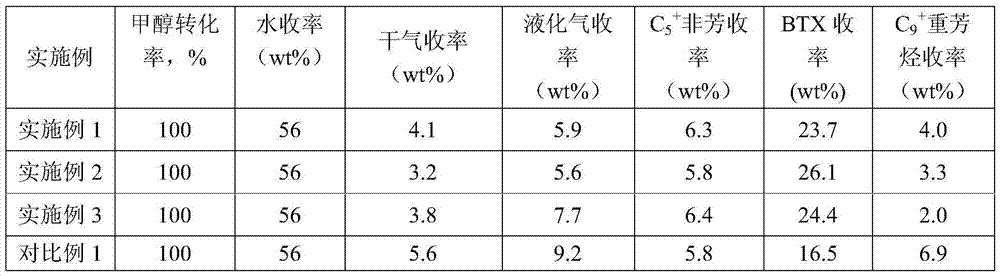

Examples

Embodiment 1

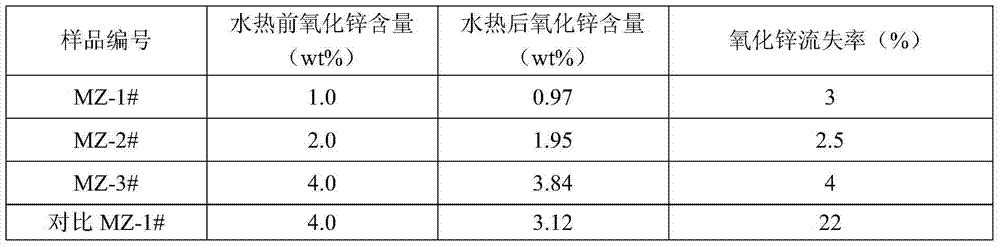

[0030] (1) Preparation of zinc-aluminum composite modified ZSM-5 molecular sieve

[0031] 100 g (dry basis weight) of SiO2 / Al 2 o 3 Nano ZSM-5 molecular sieve with a molar ratio of 30 was mixed with 750 grams of deionized water, heated to 80 °C under stirring conditions, and then 3.57 grams of Zn(NO 3 ) 2 ·6H 2 O, 36.78 g Al(NO 3 ) 3 9H 2 0; after stirring at constant temperature for 2h, adjust the slurry pH to 8 with ammonium bicarbonate; after aging with stirring at constant temperature for 3h, filter and dry to obtain zinc-aluminum modified ZSM-5 molecular sieve, the weight content of zinc oxide in molecular sieve is 1.0wt%, the weight content of aluminum oxide in molecular sieve is 5.0wt%, code is MZ-1 # ;

[0032] (2) Preparation of nickel-modified Y-type molecular sieve

[0033] 100 g (dry basis weight) of SiO 2 / Al 2 o 3 Y-type molecular sieve with a molar ratio of 5.0 was mixed with 500 grams of deionized water, heated to 75 °C under stirring conditions, a...

Embodiment 2

[0040] (1) Preparation of zinc-aluminum composite modified ZSM-5 molecular sieve

[0041] 100 g (dry basis weight) of SiO 2 / Al 2 o 3 Nano ZSM-5 molecular sieve with a molar ratio of 30 was mixed with 1000 g of deionized water, heated to 90 °C under stirring conditions, and then 3.57 g of Zn(NO 3 ) 2 ·6H 2 O, 3.53 g ZnSO 4 ·7H 2 O, 36.78 g Al(NO 3 ) 3 9H 2 O, 8.39 g Al 2 (SO 4 ) 3 ·16H 2 O; after stirring at constant temperature for 2h, adjust the pH of the slurry to 8.5 with ammonia; after aging with stirring at constant temperature for 5h, filter and dry to obtain zinc-aluminum modified ZSM-5 molecular sieve, the weight content of zinc oxide in the molecular sieve is 2.0wt %, the weight content of alumina in molecular sieve is 7.5wt%, and the code is MZ-2 # ;

[0042] (2) Preparation of nickel-modified Y-type molecular sieve

[0043] 100 g (dry basis weight) of SiO 2 / Al 2 o 3 Mix Y-type molecular sieve with a molar ratio of 5.0 and 750 grams of deionized ...

Embodiment 3

[0050] (1) Preparation of zinc-aluminum composite modified ZSM-5 molecular sieve

[0051] 100 g (dry basis weight) of SiO 2 / Al 2 o 3 Nano ZSM-5 molecular sieve with a molar ratio of 30 was mixed with 1000 grams of deionized water, heated to 85 ° C under stirring conditions, and then 6.70 grams of ZnCl were added in sequence 2 , 26.15 grams of AlCl 3 After stirring at constant temperature for 4h, adjust the slurry pH to 10 with ammonium carbonate and ammonia; after aging with stirring at constant temperature for 8h, filter and dry to obtain zinc-aluminum modified ZSM-5 molecular sieve, the weight content of zinc oxide in molecular sieve is 4.0wt%, the weight content of aluminum oxide in molecular sieve is 10wt%, code is MZ-3 # ;

[0052] (2) Preparation of nickel-modified Y-type molecular sieve

[0053] 100 g (dry basis weight) of SiO 2 / Al 2 o 3 Mix Y-type molecular sieve with a molar ratio of 5.0 with 1000 grams of deionized water, heat to 90 ° C under stirring cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com