Preparation method of scale type aluminum zinc powder using high-energy ball milling

A technology of high-energy ball milling and zinc-aluminum powder is applied in the field of preparing flake-type zinc-aluminum powder by high-energy ball milling, which can solve the problems of inability to develop water-based flake-type zinc-rich paint, complicated process, single zinc powder raw material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] 1. Material selection

[0036] Select spherical zinc powder with a particle size of 100 mesh to 325 mesh, and spherical aluminum powder with a particle size of 100 mesh to 325 mesh.

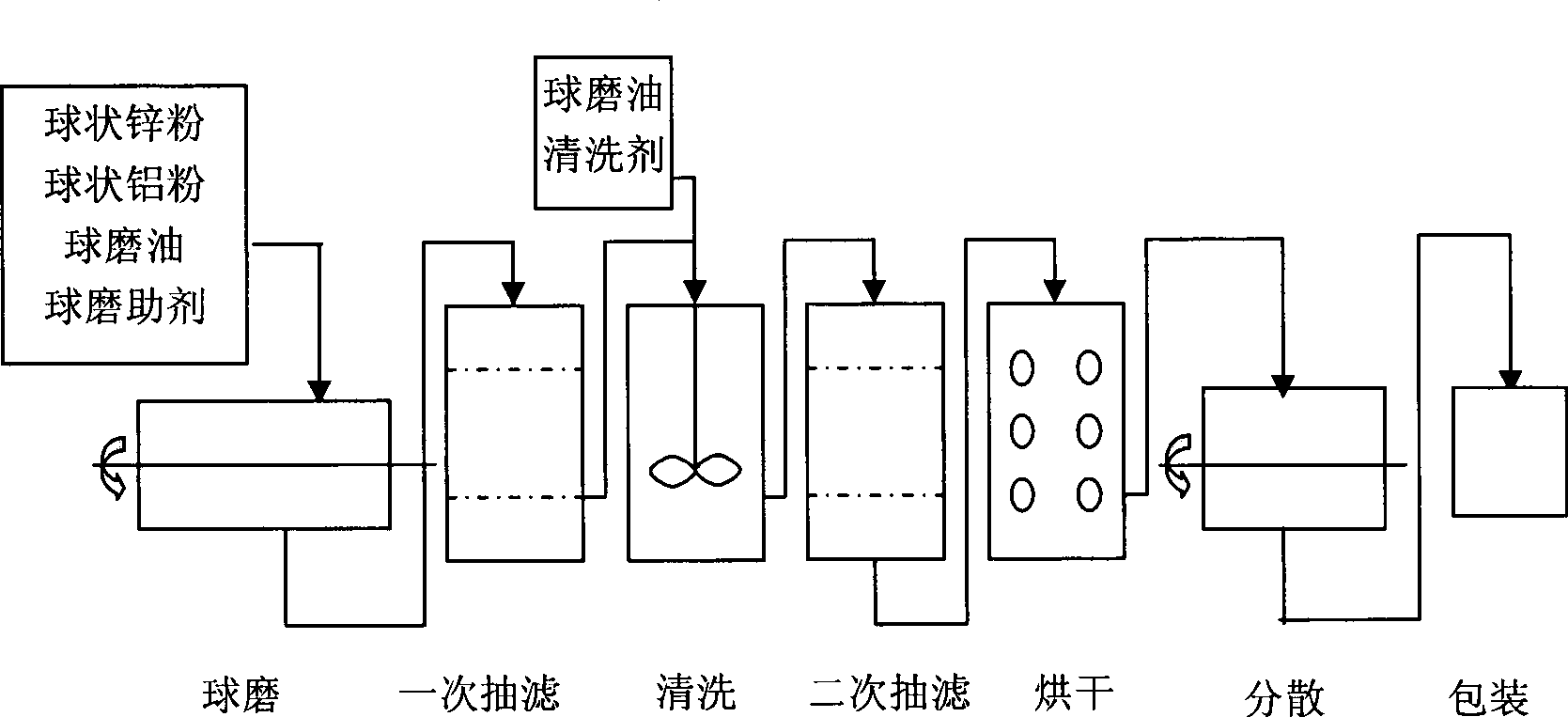

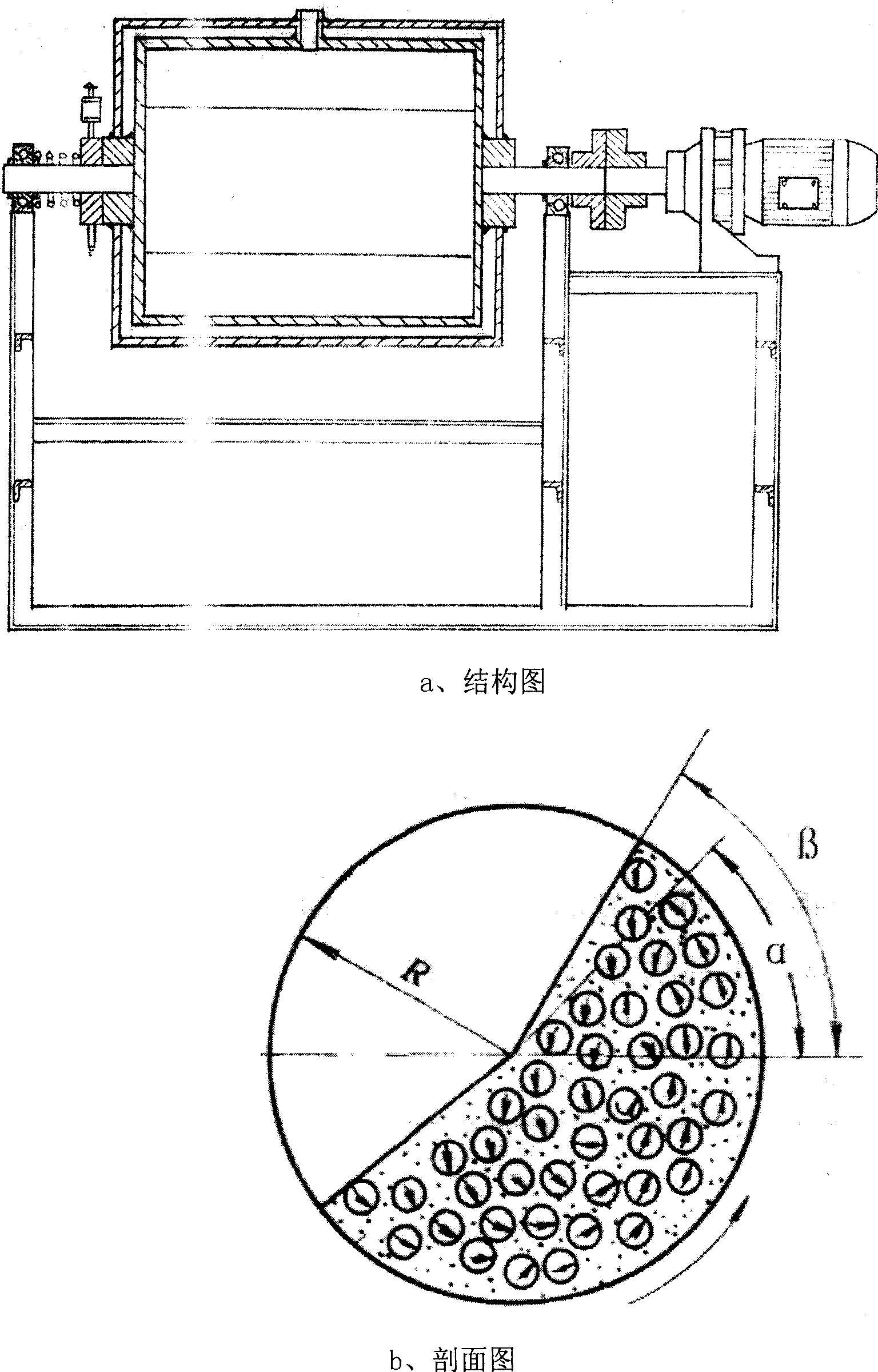

[0037] 2. Grinding

[0038] Add 150 kg of steel balls with a diameter of 5mm to 30mm and a small amount of 200# gasoline into the ball mill, then turn it on and run it idle. After cleaning the machine, empty the 200# gasoline.

[0039]Then add 55 kg of spherical zinc powder, 5 kg of spherical aluminum powder, 40 kg of 200# gasoline and 4 kg of zinc stearate, ball milling speed: 30-50 rpm, grind for 8 hours, and control the temperature of the ball mill Do not exceed 60°C.

[0040] Three, one suction filtration

[0041] A steel mesh is installed at the outlet of the ball mill to block the steel balls, and then the obtained slurry is put into a suction filter tank with a 300-mesh filter cloth, and the suction filter is used for suction filtration to remove the ball mill oil. A paste-like ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com