Nano zinc aluminum modified epoxy-fluorocarbon coating

A technology of fluorocarbon coating and aluminum modification, which is applied in the direction of epoxy resin coating, coating, etc., can solve problems that have not been found yet, and achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

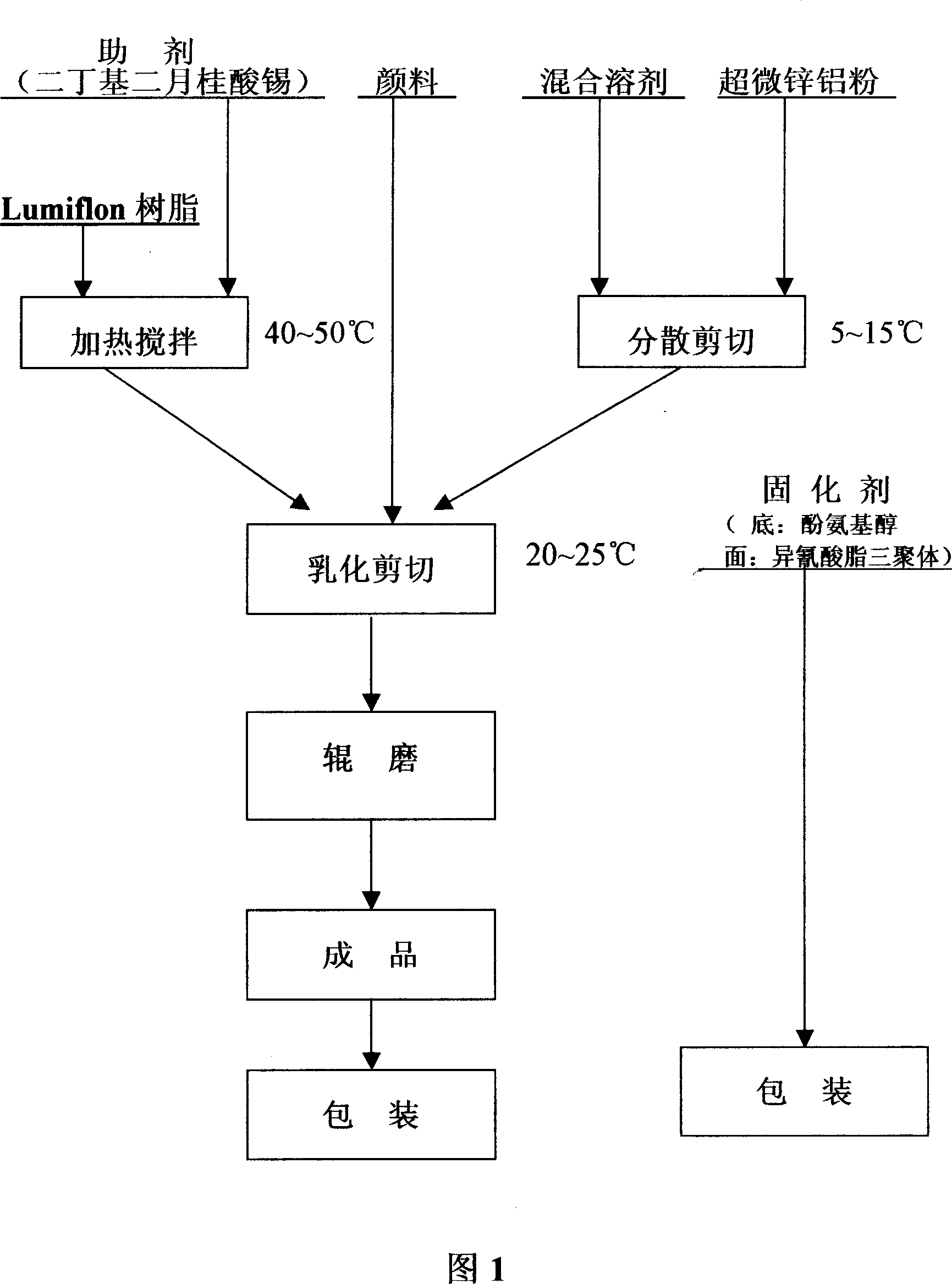

Method used

Image

Examples

Embodiment 1

[0013] The primer is composed of the following parts by mass: 90 parts of E-51 epoxy resin, 20 parts of silicone resin containing Si-OH group, the largest average diameter D 50 = 1.5 parts of 53nm nano-zinc powder, the largest average diameter D 50 = 6 parts of 775nm submicron zinc powder, 25 parts of solvent mixed with xylene and n-butanol at a ratio of 2:1, and 60 parts of phenol amino alcohol;

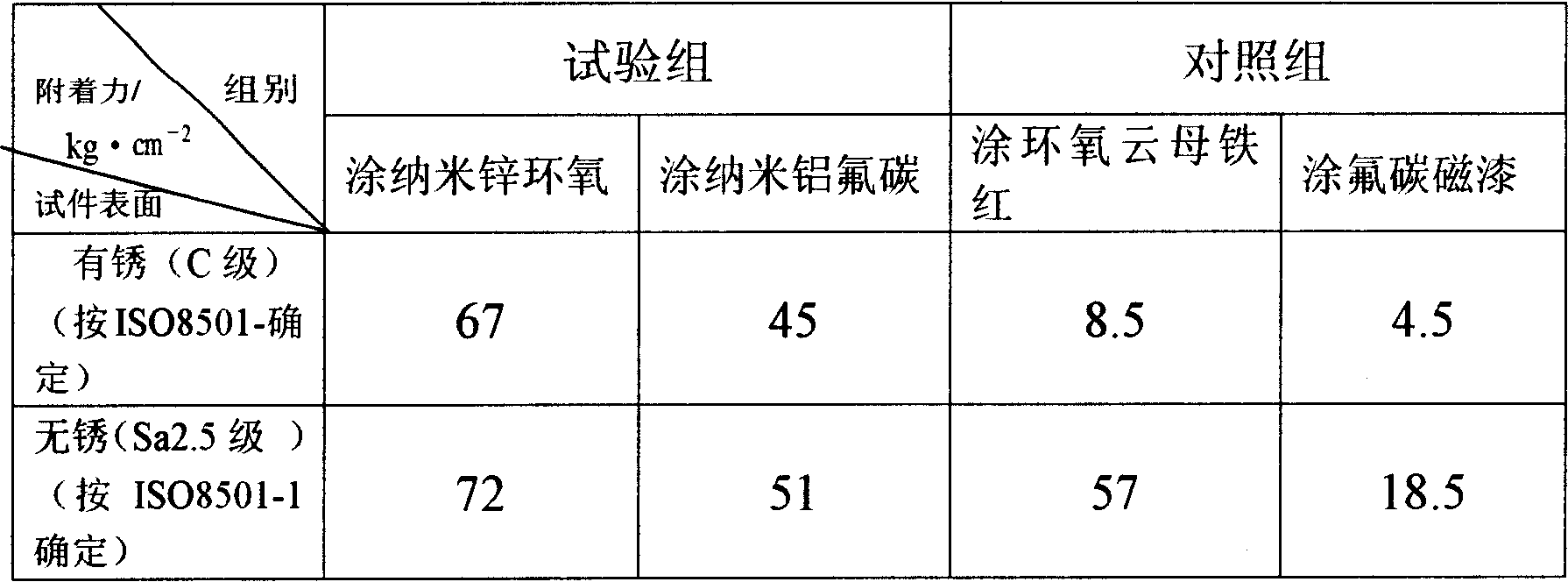

[0014] The top coating is composed of the following parts by mass: 100 parts of Lumiflon resin, 25 parts of xylene, the largest average diameter D 50 = 3.5 parts of 685nm submicron aluminum powder, 75 parts of butyl acetate, the largest average diameter D 50 = 1.5 parts of 60nm nano-aluminum powder, 0.00035 parts of dibutyltin dilaurate, 17 parts of chrome yellow pigment, and 9 parts of isocyanate trimer are mixed. The above-mentioned paint is compared with the commercially available general-purpose "Epoxy Mica Iron Red Anti-rust Paint" and the commercially available general-purpo...

example 2

[0017] The primer is composed of the following parts by mass: 90 parts of E-51 epoxy resin, 25 parts of silicone resin containing Si-OH group, the largest average diameter D 50 = 1.5 parts of 60nm nano-zinc powder, the largest average diameter D 50 = 5 parts of 726nm submicron zinc powder, 24 parts of solvent after xylene and n-butanol are mixed at 2:1, and 65 parts of phenol amino alcohol, mixed;

[0018] The top coating is composed of the following parts by mass: 100 parts of Lumiflon resin, 25 parts of xylene, the largest average diameter D 50 = 3.5 parts of 685nm submicron aluminum powder, 75 parts of butyl acetate, the largest average diameter D 50 = 1.5 parts of 60nm nano-aluminum powder, 0.00035 parts of dibutyltin dilaurate, 15 parts of chrome yellow pigment, and 9.3 parts of isocyanate trimer are mixed.

[0019] The above-mentioned paint is compared with the commercially available general-purpose "Epoxy Mica Iron Red Antirust Paint" and the commercially available ge...

Embodiment 3

[0030] The primer is composed of the following parts by mass: 100 parts of E-51 epoxy resin, 20 parts of silicone resin containing Si-OH group, the largest average diameter D 50 = 1.8 parts of 60nm nano-zinc powder, the largest average diameter D 50 = 4.5 parts of 690nm submicron zinc powder, 22 parts of solvent mixed with xylene and n-butanol at 2:1, and 60 parts of phenol amino alcohol, mixed;

[0031] The top coating is composed of the following parts by mass: 100 parts of Lumiflon resin, 25 parts of xylene, the largest average diameter D 50 = 4 parts of 820nm submicron aluminum powder, 75 parts of butyl acetate, the largest average diameter D 50 = 2 parts of 55nm nanometer aluminum powder, 0.00035 parts of dibutyltin dilaurate, 15 parts of peacock blue pigment, 9.3 parts of isocyanate trimer, mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com