Preparation method of conductive graphene/zinc aluminium oxide composite

A conductive composite material, aluminum-doped zinc oxide technology, applied in the direction of graphene, zinc oxide/zinc hydroxide, nano-carbon, etc., can solve the problems of high production cost, achieve low cost, good treatment effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Disperse 10.0 grams of graphite oxide into 1000 ml of deionized water, freeze at -15°C for 12 hours, heat at 80°C until the ice cubes basically melt, and ultrasonicate for 30 minutes at a frequency of 20KHz. Obtained graphene oxide dispersion;

[0025] 2. Add 10.6 grams of zinc sulfate and 1.5 grams of aluminum sulfate to the graphene oxide dispersion prepared in step 1, stir for 40 minutes at a temperature of 60 ° C, and then dropwise add 0.5 mol / liter of ammonium carbonate solution When the pH value of the system is 6, aging for 60 minutes, filtering and washing, the graphene oxide / ZAO precursor composite is obtained; under nitrogen atmosphere, the obtained precursor composite is calcined at 800°C for 5 hours, pulverized, and obtained Graphene / ZAO conductive composite powder; its volume resistivity is measured to be 9.71×10 -2 Ω·cm.

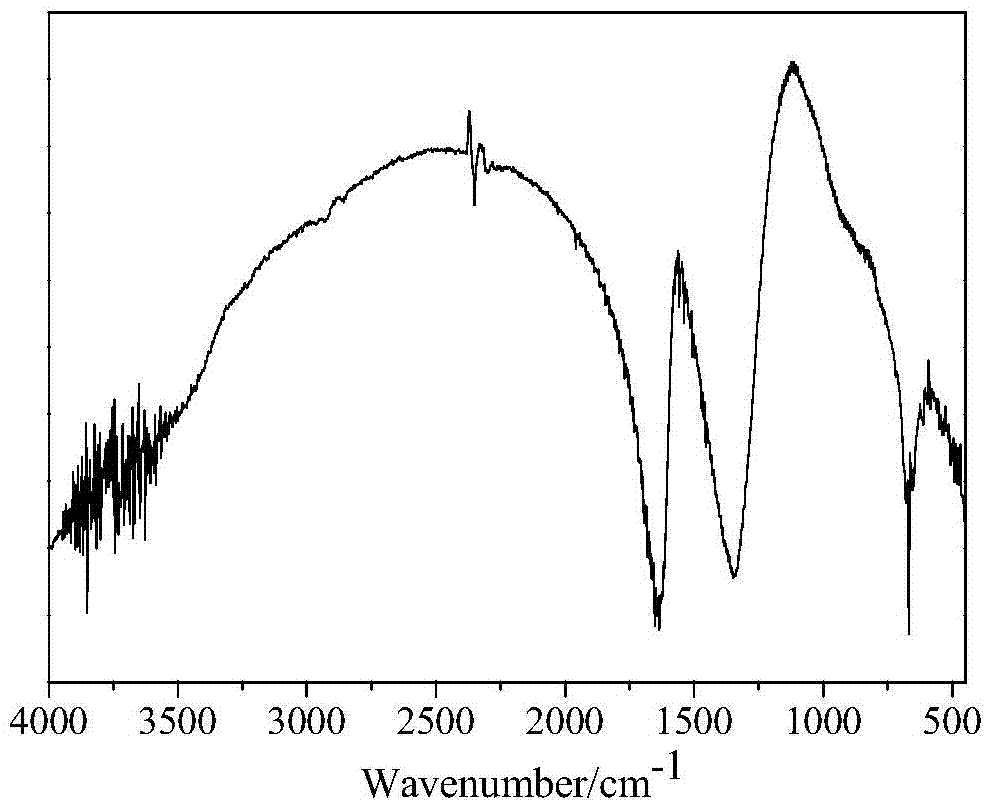

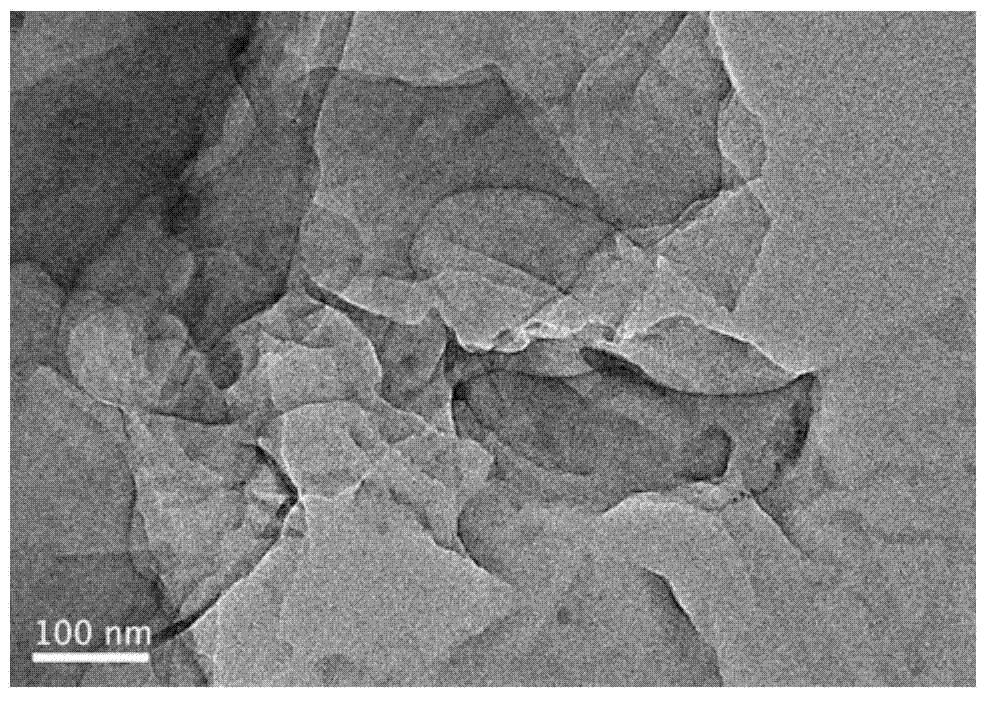

[0026] In order to verify the graphene oxide product obtained in step 1, the graphene oxide dispersion liquid obtained in this ste...

Embodiment 2

[0028] 1. Disperse 25 grams of graphite oxide into 500 ml of deionized water, freeze at -1°C for 24 hours, heat at 75°C until the ice cubes basically melt, and ultrasonicate for 60 minutes at a frequency of 40KHz. Obtained graphene oxide dispersion;

[0029] 2. Add 41.9 grams of zinc chloride and 1.1 grams of aluminum chloride to the graphene oxide dispersion prepared in step 1, stir for 20 minutes at a temperature of 80 ° C, and then dropwise add 3.0 mol / liter of carbonic acid ammonium solution until the pH value of the system is 8, aging for 30 minutes, filtering, and washing to obtain a graphene oxide / ZAO precursor composite; under a nitrogen atmosphere, the resulting precursor composite is calcined at 900°C for 1 hour, pulverized, Graphene / ZAO conductive composite powder was prepared; its volume resistivity was measured to be 2.79×10 -2 Ω·cm.

Embodiment 3

[0031] 1. Disperse 12.5 grams of graphite oxide into 500 ml of deionized water, freeze at -10°C for 18 hours, heat at 80°C until the ice cubes basically melt, and ultrasonicate for 45 minutes at a frequency of 30KHz. Obtained graphene oxide dispersion;

[0032]2. Add 29.7 grams of zinc nitrate and 0.7 grams of aluminum chloride to the graphene oxide dispersion prepared in step 1, stir for 30 minutes at a temperature of 75 ° C, and then dropwise add 1.75 mol / liter of ammonium carbonate Solution until the pH value of the system is 7.5, aging for 45 minutes, filtering, and washing to obtain a graphene oxide / ZAO precursor compound; under a nitrogen atmosphere, calcinate the obtained precursor compound at 870 ° C for 3 hours, pulverize, and prepare Graphene / ZAO conductive composite powder was obtained; its volume resistivity was measured to be 4.72×10 -2 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com