Method for preparing polymer/foam zinc-aluminium alloy composite material

A composite material, zinc-aluminum alloy technology, applied in the field of composite material preparation, can solve the problems of improving damping performance, single damping mechanism of damping material, etc., and achieve the effect of improving damping performance and high damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

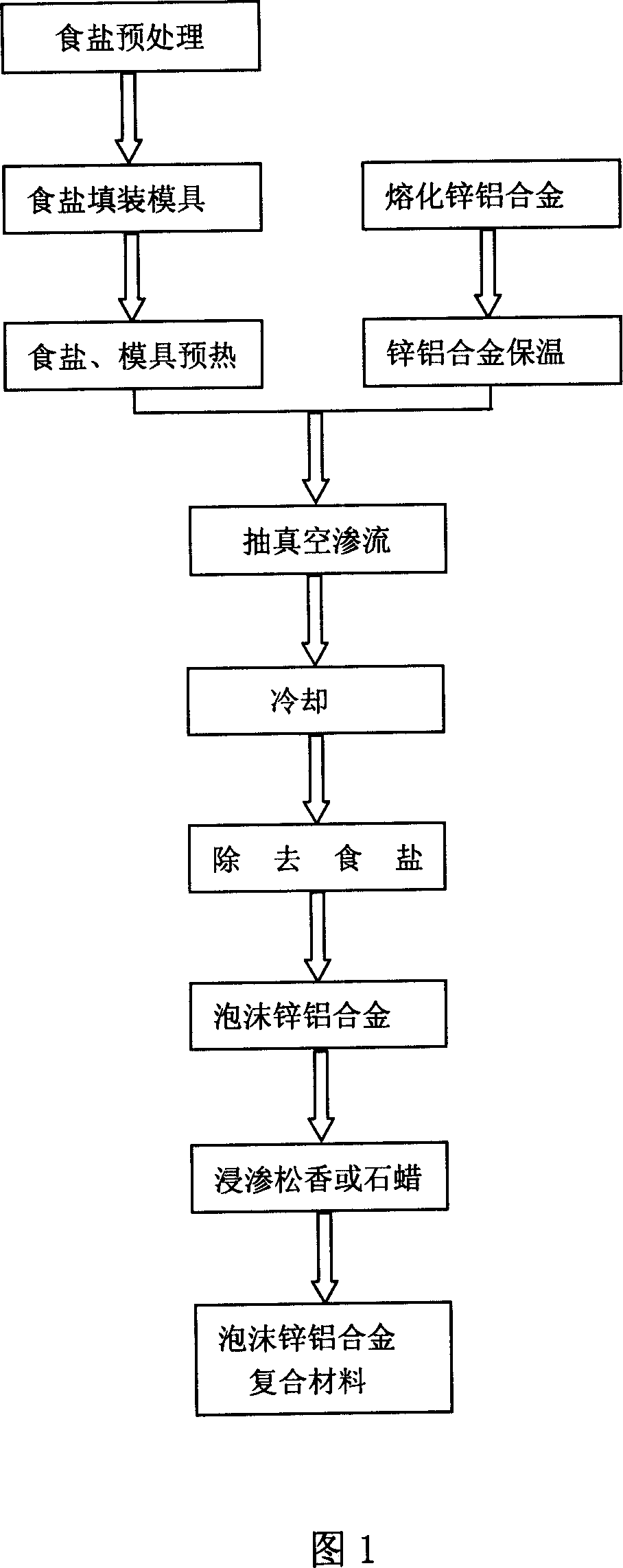

Embodiment 1

[0025] 155g of aluminum block and 419g of zinc block are prepared by conventional casting method to produce Zn-27%Al foamed zinc-aluminum alloy; the rosin is heated and melted at 150°C, kept for 15 minutes, and the foamed zinc-aluminum alloy prepared above is soaked into the liquid After heating in rosin for 10 minutes, turn off the power to cool down, and when the temperature drops to 100°C, take it out and cool it in air to obtain a polymer / foam zinc-aluminum alloy composite material.

Embodiment 2

[0027] 96.5g aluminum block and 342g zinc block were prepared by powder metallurgy to produce Zn-22%Al foamed zinc-aluminum alloy; the paraffin was heated and melted at 200°C, kept for 30 minutes, and the foamed zinc-aluminum alloy was soaked in liquid paraffin. Heat for 3 minutes, then turn off the power to cool down, and when the temperature drops to 40°C, take it out and cool it in air to obtain a polymer / foam zinc-aluminum alloy composite material.

Embodiment 3

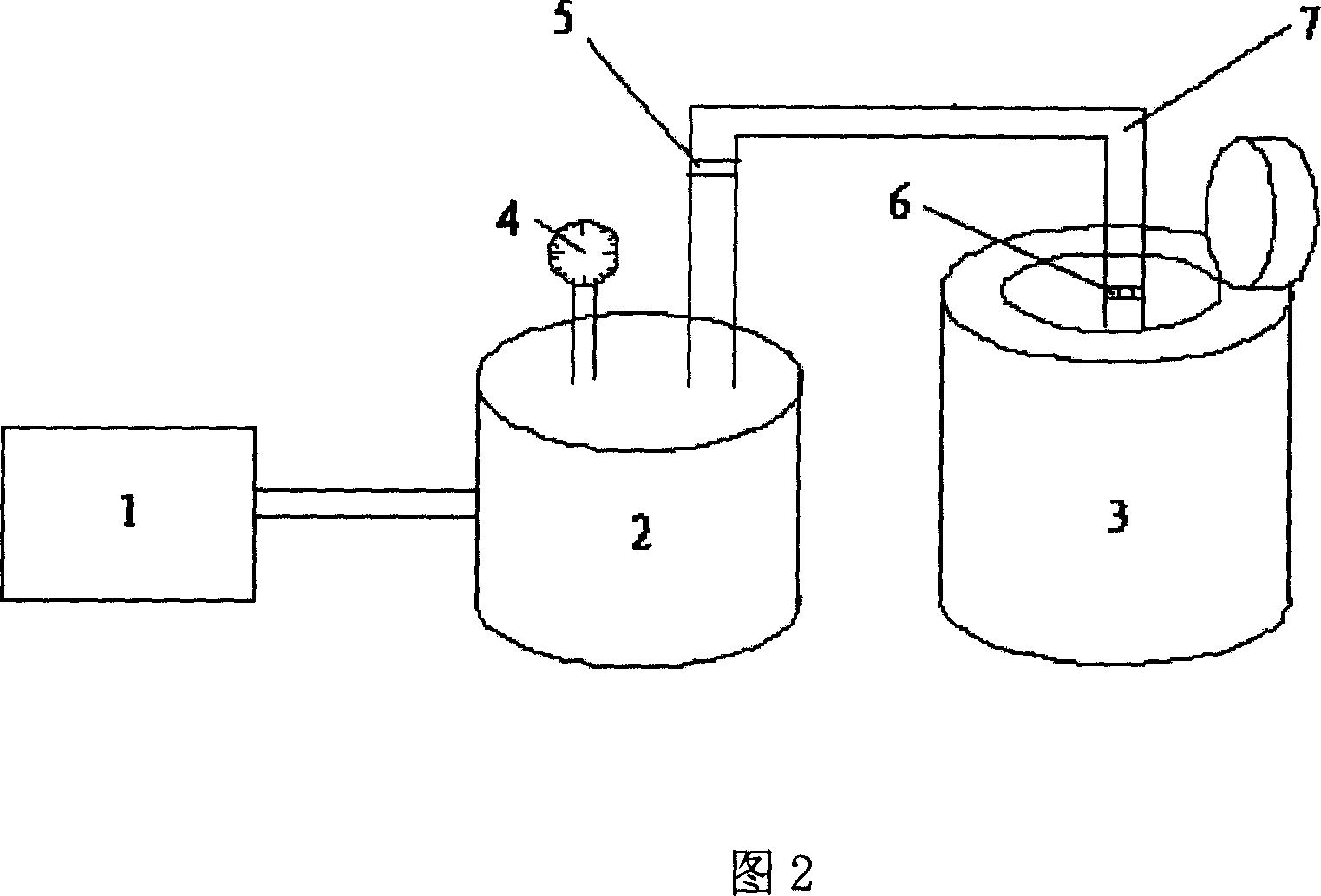

[0029] Put 155g of aluminum block into the crucible, heat to melt in the resistance furnace, then add 419g of zinc block into the crucible to prepare Zn-27%Al alloy solution, keep the Zn-27%Al alloy melt temperature at 550°C; Melt the salt, remove crystal water, crush and sieve it into 21g of salt with a diameter of 0.1mm, put it into the mold and compact it, and preheat and keep the mold with salt at 550°C, and connect the mold to Negative pressure infiltration device, and then insert the mold into the alloy melt to make it infiltrate under negative pressure for 40 seconds. After the alloy is solidified, remove the salt filler and obtain a mass of 39g, a pore diameter of 0.1mm, and a porosity of more than 80%. Φ20mm×65mm through-hole foamed Zn-27%Al alloy; put the rosin in a crucible and heat it to 200°C on an electric furnace, and after holding it for 20 minutes, soak the foamed Zn-27%Al alloy prepared above into the liquid rosin , and then heated for 5 minutes, turned off t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com