Zinc-aluminium terres rares hydrotalcite compound heat stabilizer for polyvinyl chloride (PVC) as well as preparation and application of compound heat stabilizer

A composite heat stabilizer and magnesium aluminum hydrotalcite technology, which is applied in the field of material science application technology development, can solve the problems of large rare earth ion radii and difficulty entering the hydrotalcite laminate, and achieve improved thermal stability, excellent thermal stability, The effect of enhancing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

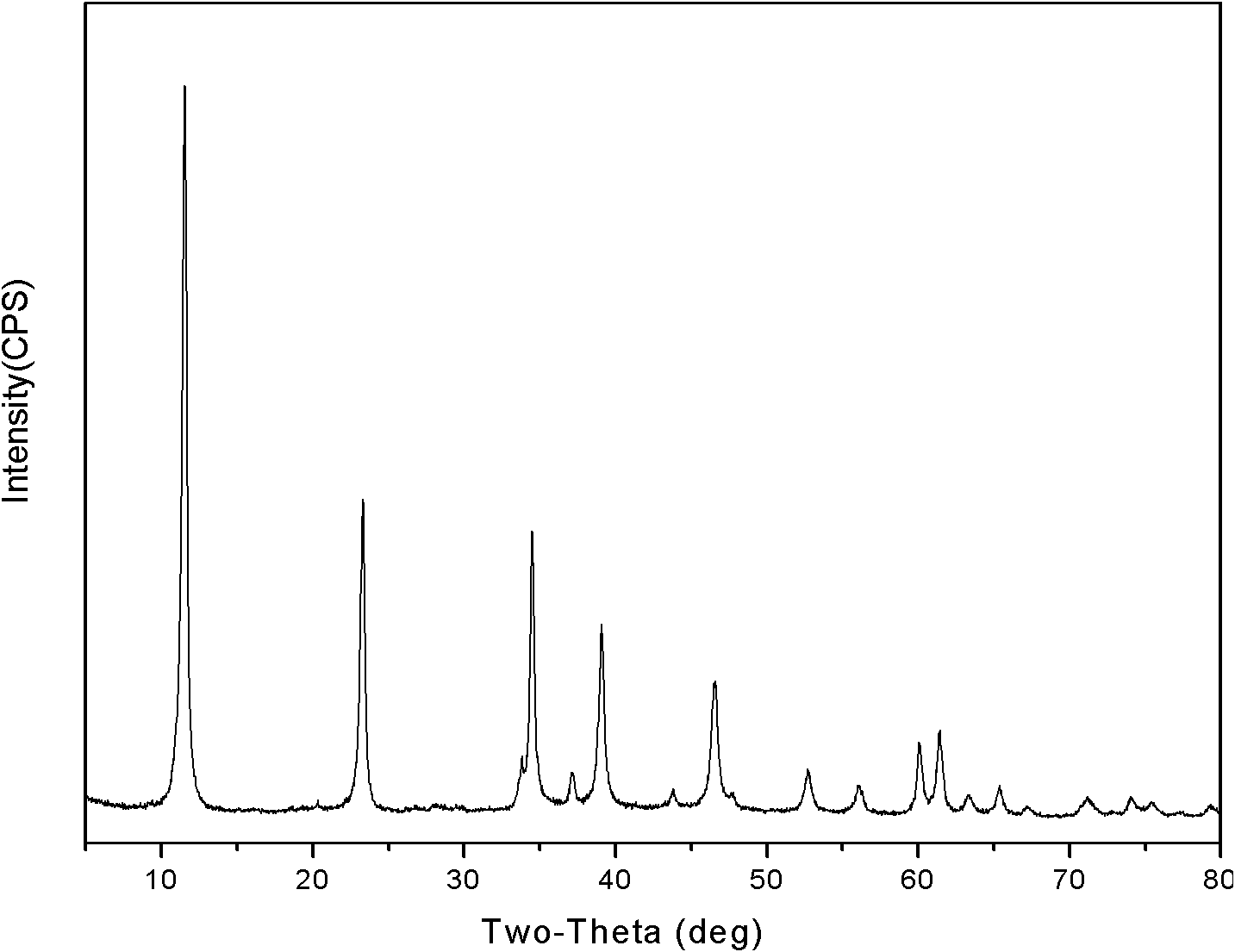

Image

Examples

Embodiment 1

[0039] Zinc-aluminum-lanthanum hydrotalcite (molar ratio: M 2+ / M 3+ =2:1, La 3+ / Al 3+ =0.1) preparation and surface modification

[0040] Weigh 29.75g Zn(NO 3 ) 2 ·6H 2 O (0.1mol), 17.07gAl (NO 3 ) 3 9H 2 O (0.0455mol), 1.97gLa (NO 3 ) 3 ·6H 2 O (0.00455mol), add deionized water to prepare a 100mL mixed solution, weigh 12.00g NaOH (0.3mol), add deionized water to prepare a 100mL solution, and mix the above two solutions at a water bath temperature of 40°C under strong stirring conditions Add dropwise to 100mL deionized water at the same time, control the pH value to 8±0.2, continue to stir for 1h after the dropwise addition, raise the temperature to 80°C and age for 24 hours, add 2.65g of anhydrous sodium carbonate, and stir at 80°C for 2 hours , filtered and washed to obtain a zinc-aluminum-lanthanum hydrotalcite filter cake. Add deionized water to the filter cake, the mass ratio of water / filter cake is 5: 1, then add sodium stearate accounting for 1.25% of the...

Embodiment 2

[0042] According to the method of embodiment 1, the molar ratio obtained is M 2+ / M 3+ =2:1, Ce 3+ / Al 3+ = 0.025 zinc aluminum cerium hydrotalcite.

Embodiment 3

[0044] According to the method of embodiment 1, the molar ratio obtained is M 2+ / M 3+ = 3:1, La 3+ / Al 3+ = 0.05 zinc aluminum lanthanum hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com