Production for conical cross winding column of S twisted yarn

A technology of cross-winding bobbins and twisting yarns, applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., to avoid the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

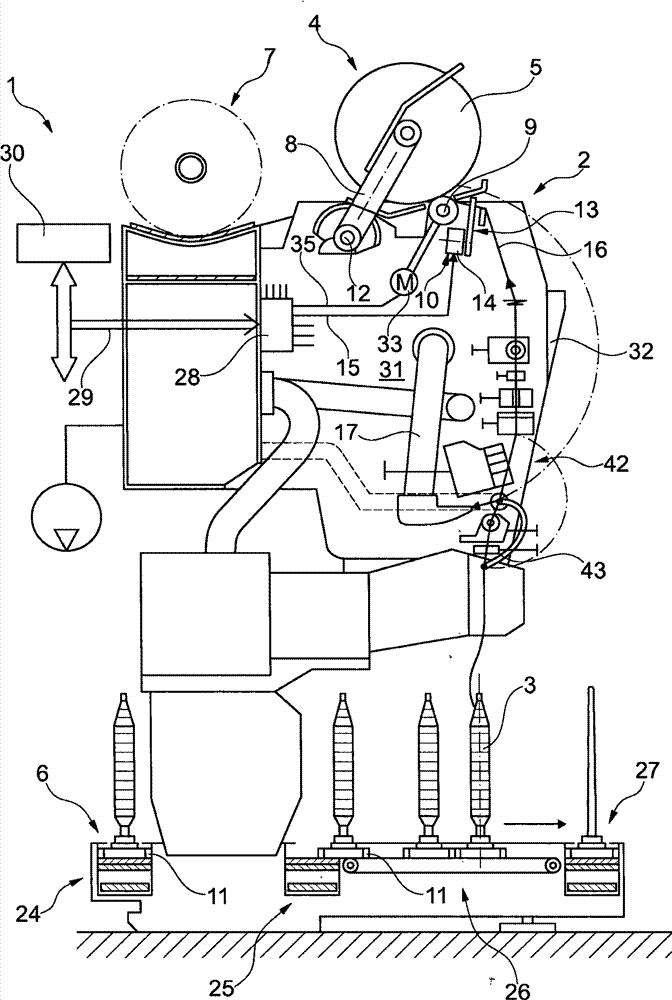

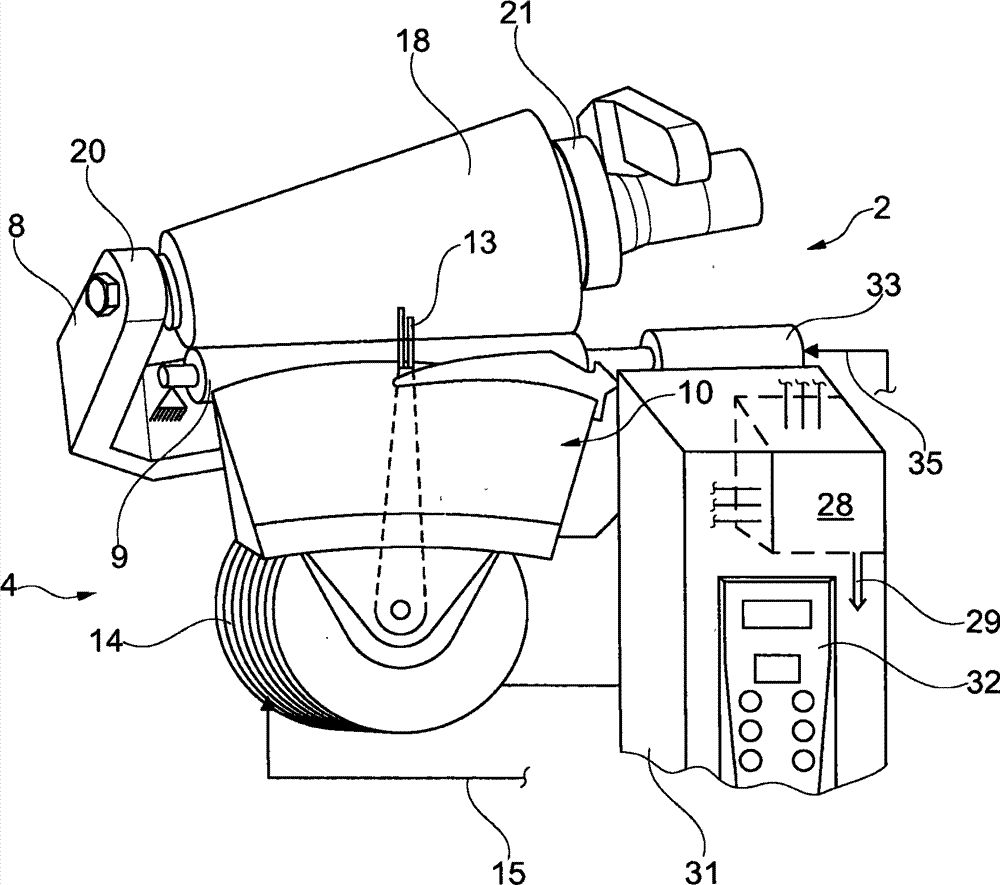

[0025] figure 1 A side view is schematically shown of a station 2 of a textile machine for producing cross-wound bobbins, in this embodiment a so-called automatic cross-winder 1 . Cops 3 having relatively little thread material and produced on ring spinning machines are rewound at station 2 of an automatic cross-winding winder 1 of this type to form bulky cross-wound bobbins 5 . Once the cross-wound bobbin 5 is formed, it is transferred to the cross-wound bobbin transfer mechanism 7 along the machine length by means of an automatically operated service assembly (not shown, preferably a cross-wound bobbin doffing machine) and transferred to the Package loading station at the end of the machine, etc.

[0026] Automatic cross-winding winders 1 of this type usually also have a logistics system in the form of a bobbin or tube delivery system 6 . Cops 3 or empty bobbins rotate on the delivery disc 11 of the bobbin or tube delivery system 6 . For bobbins or pipe delivery systems 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com