Polyurethane adhesive for flexible package of batteries

A polyurethane adhesive and flexible packaging technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of strict drawing depth and moisture resistance requirements, and products that cannot meet the requirements, and achieve good adhesion properties, excellent heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

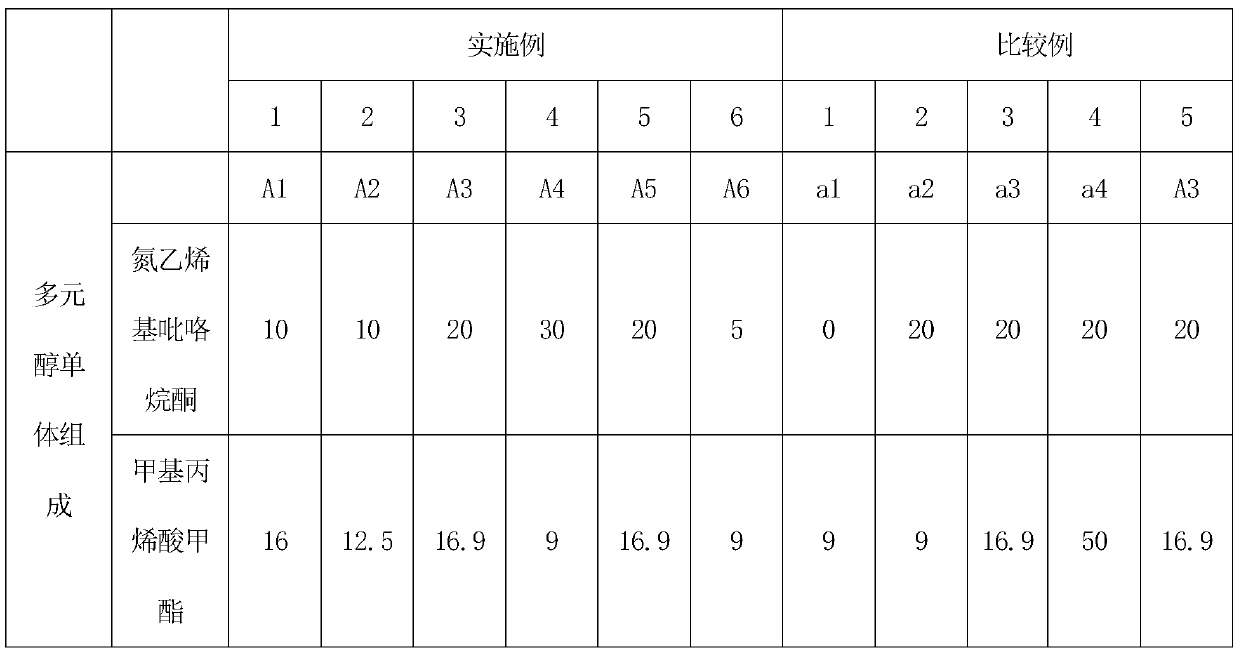

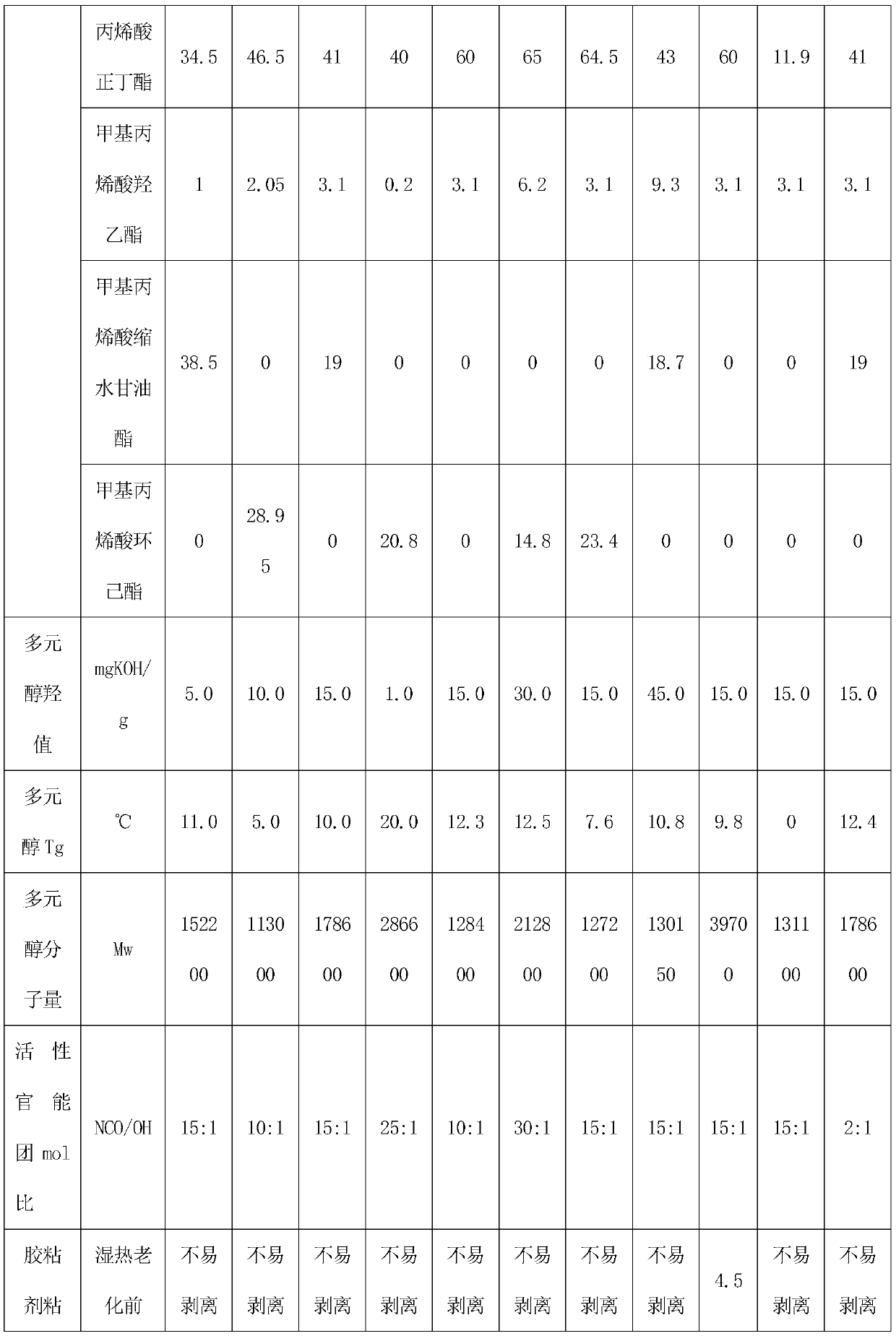

[0047] 1. Synthesis of main agent A

[0048] Add 100 parts by mass (the parts by mass here are g, the same below) ethyl acetate into a reaction kettle equipped with mechanical stirring, thermometer, reflux condenser and nitrogen protection, heat to 75°C, and 34.5 parts by mass of butyl acrylate , 16 parts by mass of methyl methacrylate, 1.0 parts by mass of hydroxyethyl methacrylate, 38.5 parts by mass of glycidyl methacrylate, 10 parts by mass of nitrogen vinyl pyrrolidone and 0.5 parts by mass of azobisisobutyronitrile , was continuously added dropwise to the reaction system within 4 hours, and 0.1 parts by mass of azobisisobutyronitrile was added after the heat preservation for 3 hours, and the heat preservation was continued for 3 hours and then lowered to room temperature to obtain the nitrogen vinyl compound modified polyacrylate polyol The solution of A has a solid content of 50%.

[0049] 2. Preparation of adhesive 1

[0050] Curing agent B (Covestro, Desmodos L 75...

Embodiment 2

[0052] 1. Synthesis of main agent A2

[0053] Add 100 parts by mass of ethyl acetate to a reactor equipped with mechanical stirring, a thermometer, a reflux condenser, and nitrogen protection, heat to 75°C, and mix 12.5 parts by mass of methyl methacrylate, 46.5 parts by mass of butyl acrylate, and 2.05 parts by mass of Parts of hydroxyethyl methacrylate, 28.95 parts by mass of cyclohexyl methacrylate, 10 parts by mass of nitrogen vinylpyrrolidone and 0.7 parts by mass of azobisisobutyronitrile were mixed uniformly, and were continuously added dropwise to the reaction system within 4 hours After 3 hours of heat preservation, 0.1 parts by mass of azobisisobutyronitrile was added, and after 3 hours of heat preservation, the solution was lowered to room temperature to obtain a solution of nitrogen vinyl compound-modified polyacrylate polyol A2 with a solid content of 50%.

[0054] 2. Preparation of adhesive 2

[0055] The curing agent B (solid content is 75wt%, NCOwt%=13.3) obta...

Embodiment 3

[0057] 1. Synthesis of main agent A3

[0058] Add 100 parts by mass of ethyl acetate to a reaction kettle equipped with mechanical stirring, thermometer, reflux condenser and nitrogen protection, heat to 75°C, mix 16.9 parts by mass of methyl methacrylate, 41 parts by mass of butyl acrylate, 3.1 parts by mass Parts of hydroxyethyl methacrylate, 19 parts by mass of glycidyl methacrylate, 20 parts by mass of nitrogen vinylpyrrolidone and 0.4 parts by mass of azobisisobutyronitrile were mixed uniformly, and were continuously added dropwise to the reaction system within 4 hours After 3 hours of heat preservation, 0.1 parts by mass of azobisisobutyronitrile was added, and after 3 hours of heat preservation, the solution was lowered to room temperature to obtain a solution of nitrogen vinyl compound-modified polyacrylate polyol A2 with a solid content of 50%.

[0059] 2. Preparation of adhesive 3

[0060] The curing agent B (solid content is 75wt%, NCOwt% = 13.3) obtained by adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com