Welding rod steel and manufacturing process thereof

A manufacturing process and welding rod steel technology, applied in the field of welding rod steel and its manufacturing process, can solve the problems that affect the smooth production, defects in welding performance and drawing performance, easy to cause nodules, etc., so as to ensure smooth production and good drawing Pulling performance and welding performance, the effect of preventing nozzle nodulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

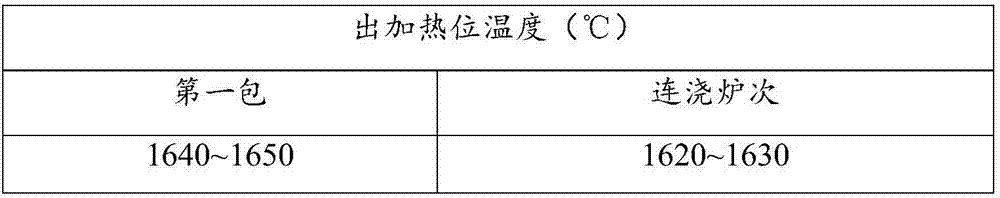

[0071] This embodiment provides a manufacturing process of welding rod steel, which includes the following steps.

[0072] S1, smelting steps

[0073] Using molten iron as raw material, the composition of molten iron is Si: 0.20wt%, Mn: 0.20wt%, P≤0.120wt%, S≤0.025wt%, Cr≤0.10wt%, Ni≤0.10wt%, Cu≤0.15wt% , As≤0.015wt%. The temperature of molten iron is 1200°C. According to the loading capacity of 97.5t, it enters the 100t converter for smelting. Add slag material in batches to make slag.

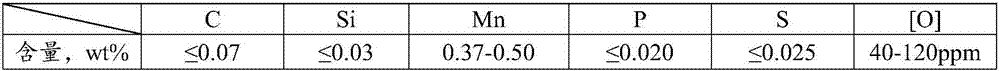

[0074] The deoxidation alloying operation is carried out during the tapping process, and the tapping time is 3.5 minutes. The tapping adopts double slag blocking, and the thickness of the ladle slag layer is 40mm. The tapping temperature is 1600°C. After the deoxidation alloying operation, that is, before entering the refining step, the composition of molten steel is controlled to

[0075]

[0076] S2, refining step

[0077] The molten steel obtained in the smelting step is first bl...

Embodiment 2

[0089] This embodiment provides a manufacturing process of welding rod steel, which includes the following steps.

[0090] S1, smelting steps

[0091] Using molten iron and some scrap steel as raw materials, the composition of molten iron is Si: 0.60wt%, Mn: 0.50wt%, P≤0.120wt%, S≤0.025wt%, Cr≤0.10wt%, Ni≤0.10wt%, Cu≤ 0.15wt%, As≤0.015wt%. The temperature of molten iron is 1200°C. According to the loading capacity of 98.5t, it enters the 100t converter for smelting. Add slag material in batches to make slag.

[0092] The deoxidation alloying operation is carried out during the tapping process, and the tapping time is 3.5 minutes. The tapping adopts double slag blocking, and the thickness of the ladle slag layer is 50 mm. This embodiment is the first ladle of molten steel, so the tapping temperature is 1630°C. After the deoxidation alloying operation, that is, before entering the refining step, the composition of molten steel is controlled to

[0093]

[0094] S2, refi...

Embodiment 3

[0107] This embodiment provides a manufacturing process of welding rod steel, which includes the following steps.

[0108] S1, smelting steps

[0109]Using molten iron and some scrap steel as raw materials, the composition of molten iron is Si: 0.80wt%, Mn: 0.80wt%, P≤0.120wt%, S≤0.025wt%, Cr≤0.10wt%, Ni≤0.10wt%, Cu≤ 0.15wt%, As≤0.015wt%. The temperature of molten iron is 1200°C. According to the loading capacity of 99.5t, it enters the 100t converter for smelting. Add slag material in batches to make slag.

[0110] The deoxidation alloying operation is carried out during the tapping process, and the tapping time is 3.5 minutes. The tapping adopts double slag blocking, and the thickness of the ladle slag layer is 50 mm. The tapping temperature is 1620°C. After the deoxidation alloying operation, that is, before entering the refining step, the composition of molten steel is controlled to

[0111]

[0112] S2, refining step

[0113] The molten steel obtained in the sme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com