High-temperature-resistant aluminum-plastic composite film

A technology of aluminum-plastic composite film and high temperature resistance, which is applied in the field of aluminum-plastic composite film, can solve the problems of nylon surface damage and whitening, and achieve the effect of simple operation method, reduced friction and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

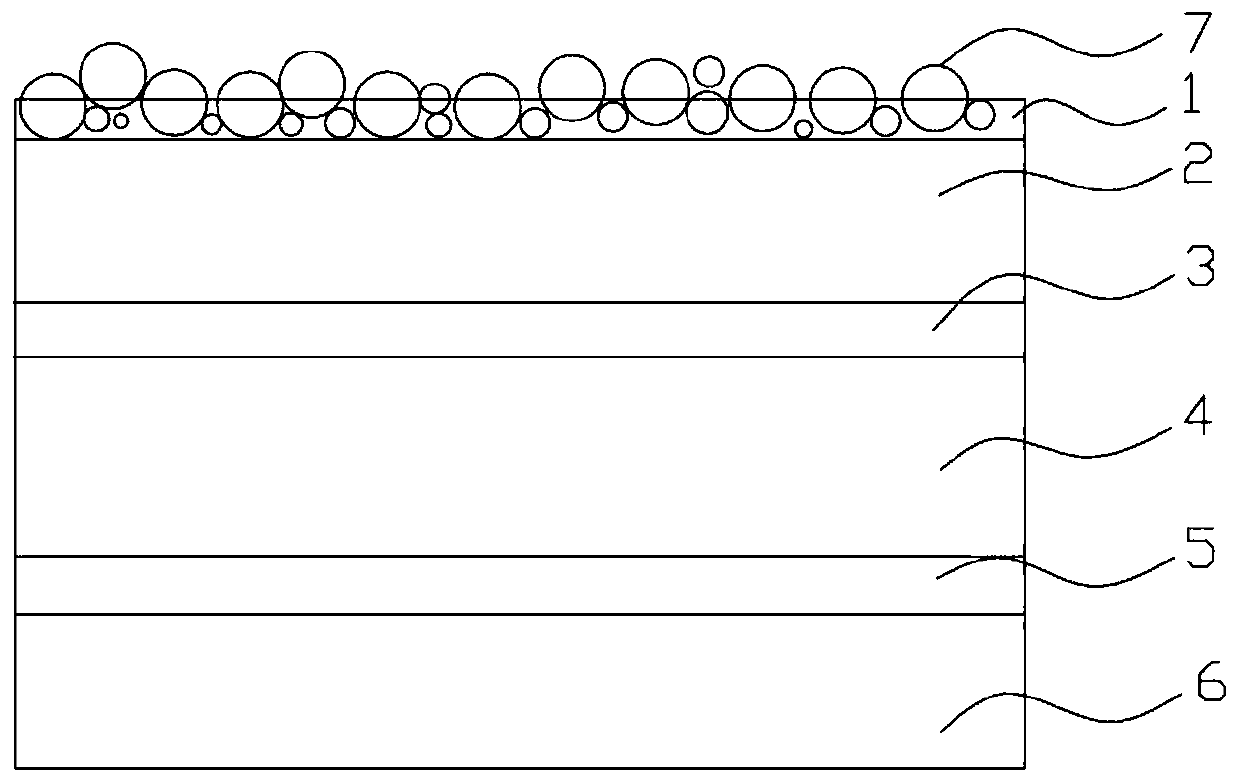

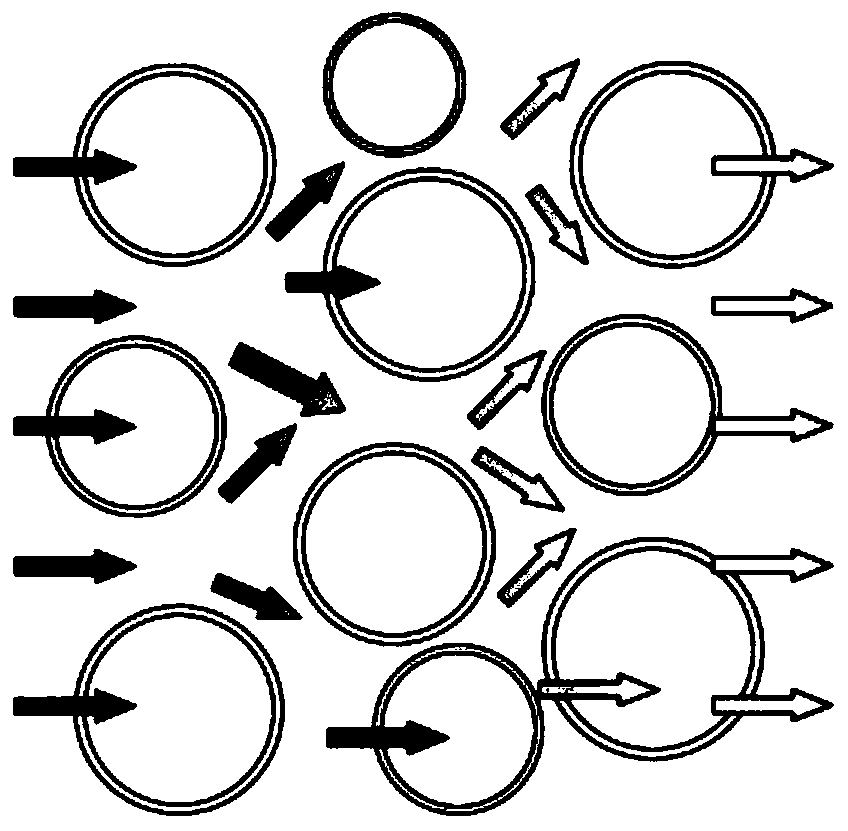

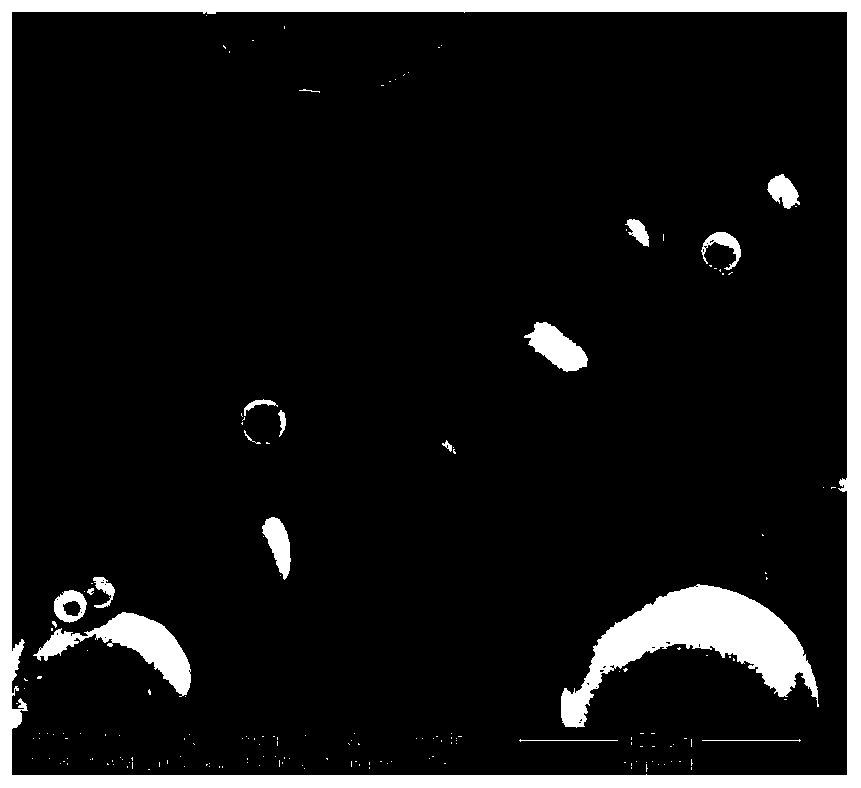

[0041] The coating of the matte layer 1 uses a micro-gravure roller coating, and the number of meshes is 105 lines; the thickness of the matte layer 1 is 3.5 μm; the volume fraction of the hollow glass microspheres 7 is 10%; the wall thickness of the hollow glass microspheres 7 1.2μm; hollow glass microsphere 7 is SiO 2 ; The formula of matte layer 1 is polyester polyol + hollow glass microspheres 60%, IPDI + HDI 20%, toluene 15%, additive 5%, wherein, IPDI:HDI ratio is 9:1. The nylon layer 2 is double drawn nylon with a thickness of 25 μm; the second adhesive layer 5 is made of polyurethane two-component adhesive, which is coated, dried and pressed on the aluminum foil layer 4 by an anilox roller. The thickness of the second adhesive layer 5 is 5 μm; the thickness of the aluminum foil layer 4 is 40 μm; the first adhesive layer 3 is made of polyurethane two-component adhesive, coated and dried on the aluminum foil layer 4 by an anilox roll. The first adhesive layer 3 has a th...

Embodiment 2

[0043] The coating of the matte layer 1 uses a micro-gravure roller coating, and the mesh number is selected as 105 lines; the thickness of the matte layer 1 is 3 μm; the volume fraction of the hollow glass microspheres 7 is 10%; the material of the hollow glass microspheres 7 is MgO , the wall thickness of the hollow glass microspheres 7 is 1.8 μm; the formula of the matte layer 1 is polyester polyol + hollow glass microspheres 70%, HDI 4%, and toluene 26%. The nylon layer 2 is double drawn nylon with a thickness of 20 μm; the second adhesive layer 5 is made of polyurethane two-component adhesive, which is coated, dried, and pressed on the aluminum foil layer 4 by an anvil roll. The thickness of the second adhesive layer 5 is 5 μm; the thickness of the aluminum foil layer 4 is 36 μm; the first adhesive layer 3 is made of polyurethane two-component adhesive, coated, dried and laminated on the aluminum foil layer 4 by an anvil roller. The first adhesive layer 3 has a thickness of...

Embodiment 3

[0045] The coating of the matte layer 1 uses micro-gravure roller coating, and the mesh number selects 105 lines; the thickness of the matte layer 1 is 4 μm; the volume fraction of the hollow glass microspheres 7 is 30%; the wall thickness of the hollow glass microspheres 7 is 2.2 μm; the material of the hollow glass microsphere 7 is Al 2 o 3 The formula of the matte layer 1 is acrylic + hollow glass microspheres 60%, IPDI + HDI 20%, toluene 15%, additives 5%, wherein, IPDI:HDI is 9:1. The nylon layer 2 is 30 μm double-drawn nylon; the second adhesive layer 5 is made of polyurethane two-component adhesive, which is coated, dried and pressed on the aluminum foil layer 4 by an anvil roll. The thickness of the second adhesive layer 5 is 5 μm; the thickness of the aluminum foil layer 4 is 44 μm; the first adhesive layer 3 is made of polyurethane two-component adhesive, coated and dried on the aluminum foil layer 4 by an anilox roll. The first adhesive layer 3 has a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com