Drahtstahl for high strength fastening piece and production method thereof

A fastener and high-strength technology, applied in the direction of metal rolling, can solve problems such as prolonging the transformation time, and achieve the effect of improving cold deformation ability, excellent drawability and steel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

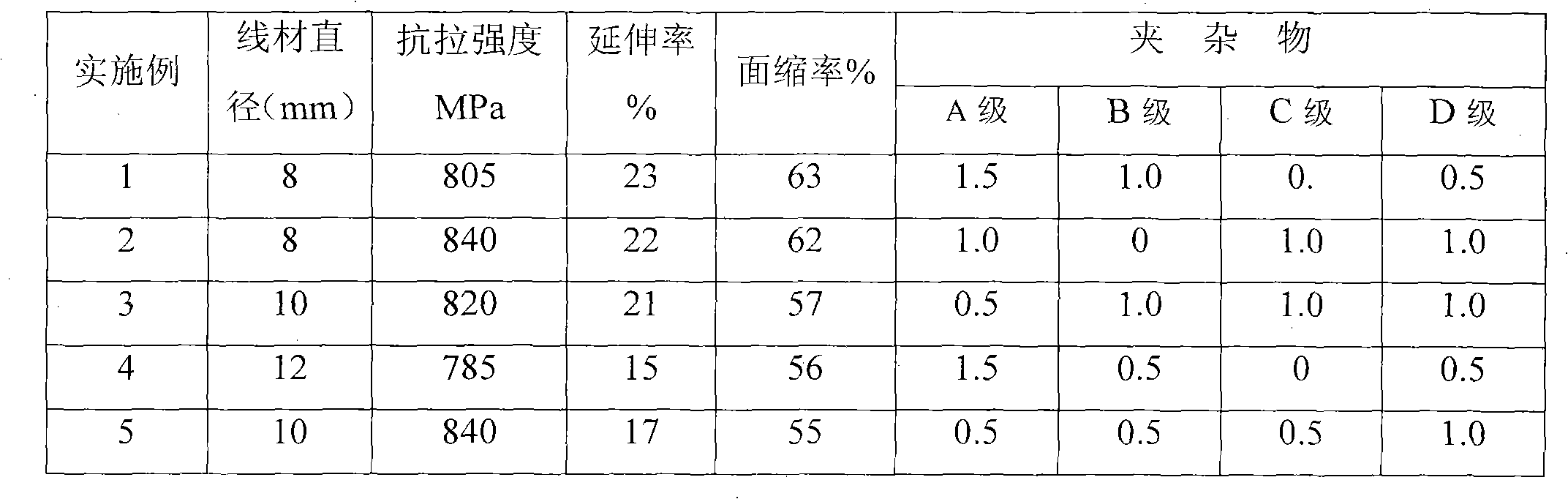

Examples

Embodiment 1

[0036] A wire steel for high-strength fasteners, its composition and weight percentage are: C: 0.39, Si: 0.15, Mn: 0.60, Cr: 0.60, Als: 0.010, P≤0.035, S≤0.035, and the rest is Fe and unavoidable impurities.

[0037] Its production steps:

[0038] 1) The components and weight percentages are: C: 0.39, Si: 0.15, Mn: 0.60, Cr: 0.60, Als: 0.010, P≤0.035, S≤0.035, and the rest are Fe and unavoidable impurities. Converter clean steel process for smelting and continuous casting into billets, adding 320 meters of Si-Ca wire for each furnace of steel during refining, controlling the input speed of Si-Ca wire to 28 m / s, and the alkalinity of steel slag in the ladle to 2.45 ;

[0039] 2) Heating the 200×200mm continuous casting slab to 980°C;

[0040] 3) Rough rolling: the continuous casting slab is rough rolled through 6 stands at 980°C, and the deformation is 70%;

[0041] 4) Intermediate rolling with 10 stands: control its deformation at 80%;

[0042] 5) Carry out pre-finish rol...

Embodiment 2

[0050] A wire steel for high-strength fasteners, its composition and weight percentage are: C: 0.434, Si: 0.256, Mn: 0.704, P: 0.015, S: 0.008, Cr: 1.008, Als: 0.0187, P≤0.035 , S≤0.035, and the rest are Fe and unavoidable impurities.

[0051] Its production steps:

[0052] 1) The components and weight percentages are: C: 0.434, Si: 0.256, Mn: 0.704, P: 0.015, S: 0.008, Cr: 1.008, Als: 0.0187, P≤0.035, S≤0.035, and the rest are Fe and The steel composition of unavoidable impurities is smelted by converter clean steel process and continuously cast into slabs. During refining, 355 meters of Si-Ca wire is added to each furnace of steel, and the input speed of Si-Ca wire is controlled to 29 m / s. The basicity of the steel slag in the ladle is 2.40;

[0053] 2) Heating the 200×200mm continuous casting slab to 995°C;

[0054] 3) Rough rolling: the continuous casting slab is rough rolled through 6 stands at 995°C, and the deformation is 73%;

[0055] 4) Intermediate rolling with 10 ...

Embodiment 3

[0064] A wire steel for high-strength fasteners, its composition and weight percentage are: C: 0.407, Si: 0.219, Mn: 0.718, P: 0.015, S: 0.009, Cr: 0.971, Als: 0.0242, P≤0.035 , S≤0.035, and the rest are Fe and unavoidable impurities.

[0065] Its production steps:

[0066] 1) The components and weight percentages are: C: 0.407, Si: 0.219, Mn: 0.718, P: 0.015, S: 0.009, Cr: 0.971, Als: 0.0242, P≤0.035, S≤0.035, and the rest are Fe and The steel composition of unavoidable impurities is smelted by converter clean steel process and continuously cast into slabs. During refining, 400 meters of Si-Ca wire is added to each furnace of steel, and the input speed of Si-Ca wire is controlled to be 30 m / s. The basicity of the steel slag in the ladle is 2.35;

[0067] 2) Heating the 200×200mm continuous casting slab to 1010°C;

[0068] 3) Rough rolling: the continuous casting slab is rough rolled through 6 stands at 1010°C, and the deformation is 75%;

[0069] 4) Intermediate rolling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com