Ultrasonic arc laminating and rolling thin-wall steel tube welding device and welding method

A thin-walled steel pipe and ultrasonic arc technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of difficult weld forming control and application implementation, difficult determination of modifier components, and difficult application, etc., to achieve Promote the crystallization process of molten pool, reduce the residual stress, improve the effect of internal quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

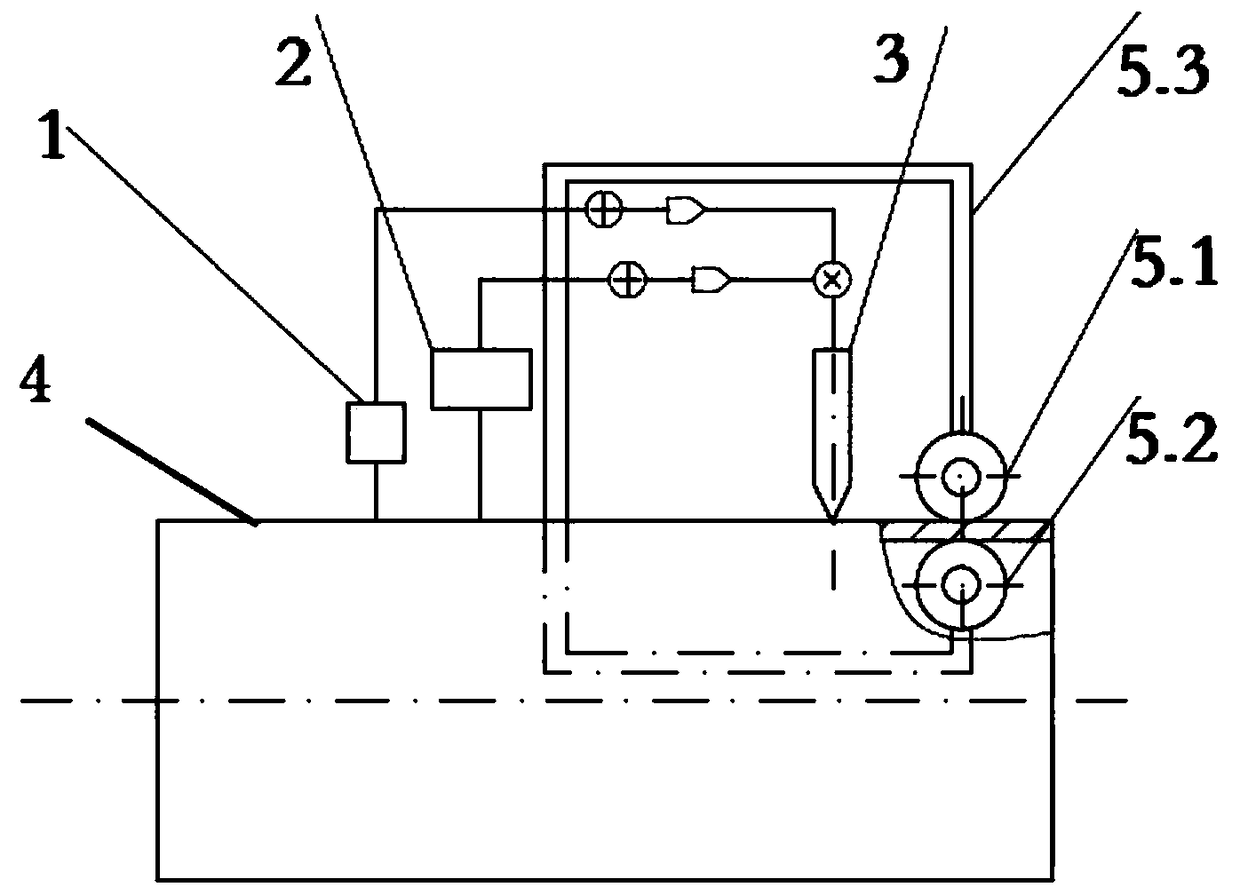

[0032] combine figure 1 As shown, the welding device for ultrasonic arc lamination and rolling of thin-walled steel pipes includes an ultrasonic arc generating device and a rolling lamination device.

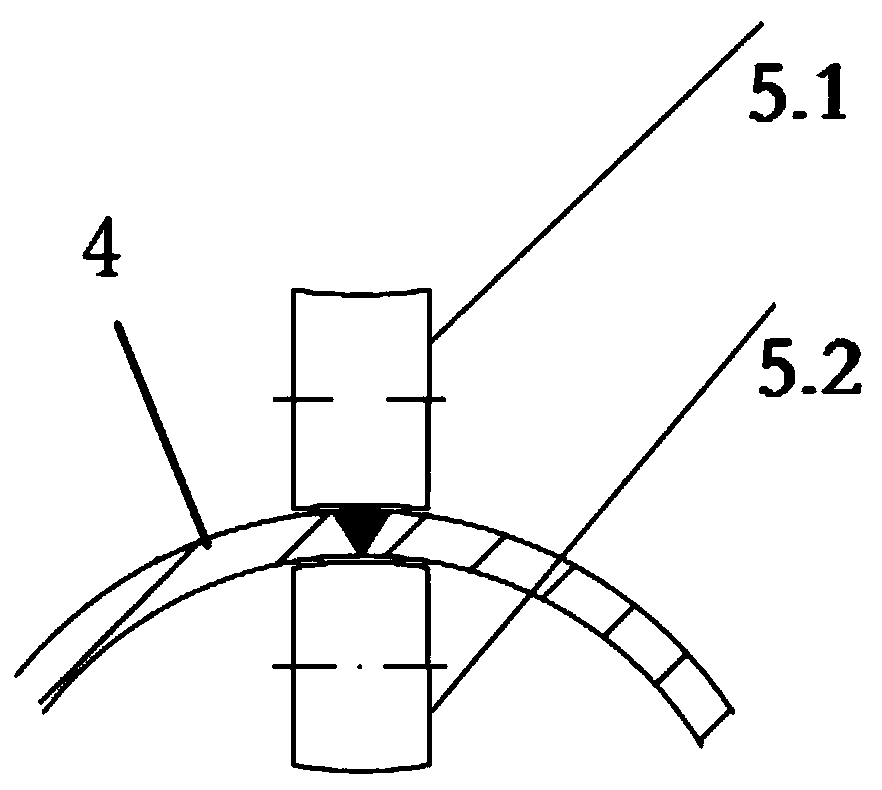

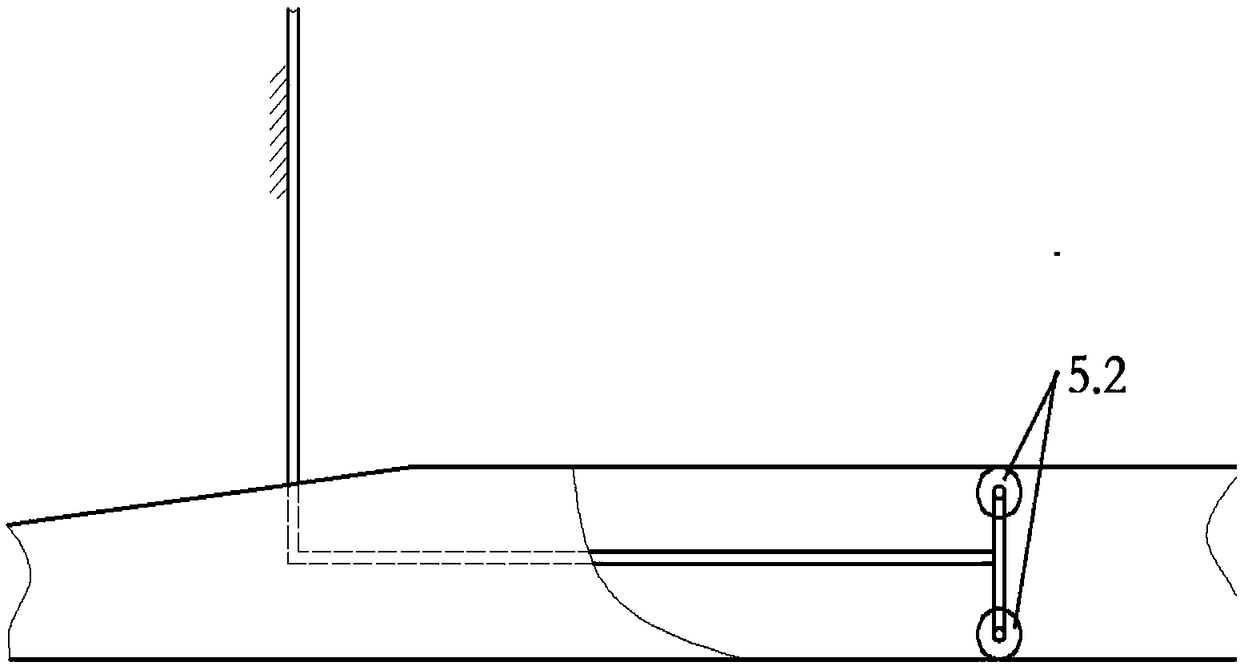

[0033] combine figure 2 As shown, the rolling laminating device includes an upper rolling laminating wheel 5.1, a lower rolling laminating wheel 5.2 and a connecting bracket 5.3; the upper rolling laminating wheel 5.1 is mounted on a thin-walled steel pipe 4 The outer wall surface of the upper rolling and fitting wheel 5.1 radian curvature matches the outer diameter of the thin-walled steel pipe 4; the lower rolling and fitting wheel 5.2 is mounted on the inner wall of the thin-walled steel pipe 4 with zero clearance, and The radian curvature of the lower rolling and fitting wheel 5.2 matches the inner diameter of the thin-walled steel pipe 4; the positions of the upper rolling and fitting wheel 5.1 and the lower rolling and fitting wheel 5.2 correspond; the first end of the c...

Embodiment 2

[0043] The patent of the invention can improve weld seam defects of welded steel pipes and reduce the probability of cracking in the subsequent drawing process. In order to illustrate the treatment effect of the patented welded steel pipe of the present invention, 2507 duplex stainless steel provided by Shanghai Baosteel was selected as the base material for the test in Example 2.

[0044] 1) Selection of raw materials

[0045] The size of the steel strip is 2000mm×60mm×1mm, and the main chemical composition and mechanical properties are shown in Table 1 and Table 2:

[0046] The chemical composition (wt.%) of table 1 steel strip

[0047]

[0048] Table 2 Steel Strip Mechanical Properties

[0049]

[0050] 2) Welding method and equipment selection

[0051] Use a steel strip with a size of 2000mm×60mm×1mm to roll up the butt self-fusion welding, and first use acetone to remove the oil on the surface of the steel strip to ensure that there is no pollutant in the area to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com