Production method for optimizing drawing performance of steel wire rod for carbon steel welding wire

A production method and wire rod technology, applied in temperature control, metal rolling, etc., can solve problems such as deterioration of wire rod drawing performance, limited length of slow cooling zone, loss of wire rod yield, etc., to eliminate frequent brittle fractures , The length of the slow cooling zone is shortened, and the effect of tapping the potential of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

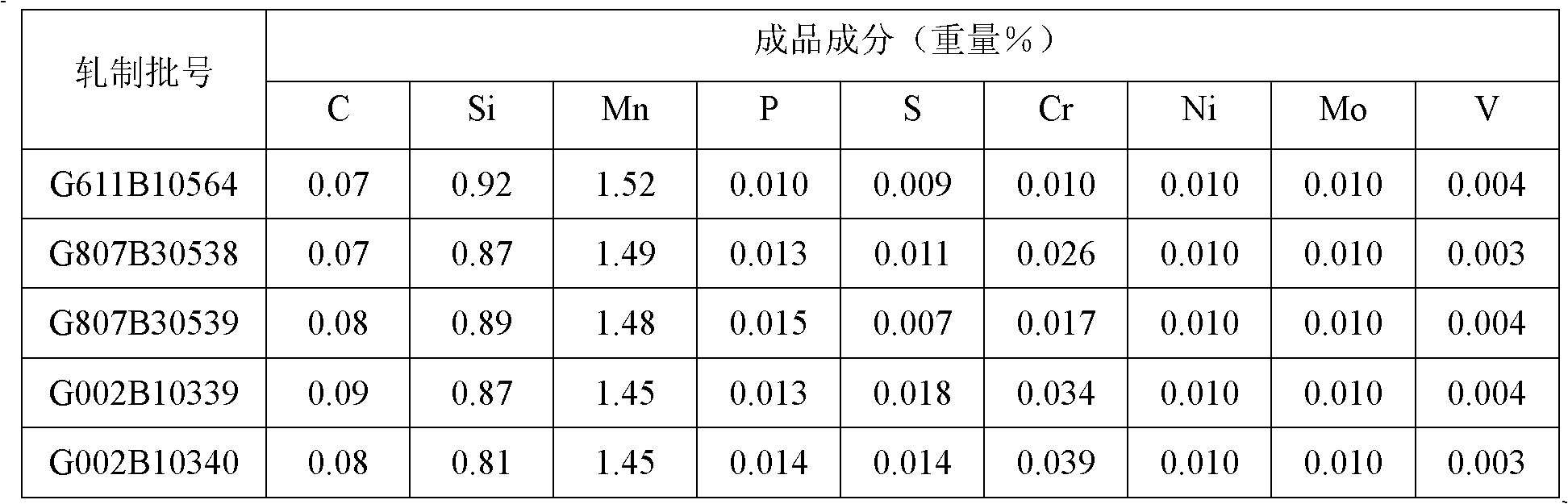

[0020] The present invention can be implemented in a steel rolling mill with a slow cooling zone. The following Tables 1 to 5 list the key parameter examples of the production process when the high-speed wire rod plant of Shougang adopts the present invention to produce products such as wire rods for carbon steel welding wire ER50-6.

[0021] Table 1 Chemical Composition of Finished Products

[0022]

[0023] Table 2 Rolling process temperature, ℃

[0024] Rolling lot number

[0025] Table 3 Roller speed in heat preservation area, m / s

[0026] Rolling lot number

[0027] G807B30539

[0028] Table 4 Sampling test results of mechanical properties of wire rod

[0029]

[0030] Table 5 Sampling test results of wire rod tissue

[0031] Rolling lot number

[0032] As an efficient welding material, gas shielded welding wire is one of the main development directions of welding materials in the future. However, my country's national cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com