Rutile flux-cored wire with tensile strength of 800 MPa grade and preparation method thereof

A technology of flux-cored welding wire and tensile strength, which is applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of slow deposition speed of welding rod and can not meet the needs of users for all positions, and achieve the purpose of improving the performance of welding wire, Welding process performance and physical and chemical properties are good, and the effect of spatter is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

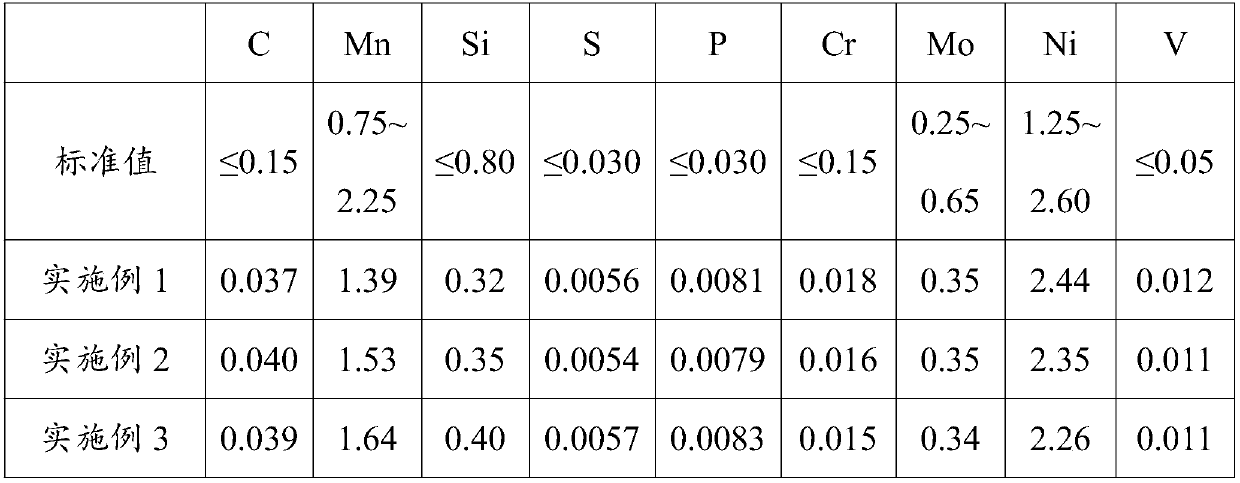

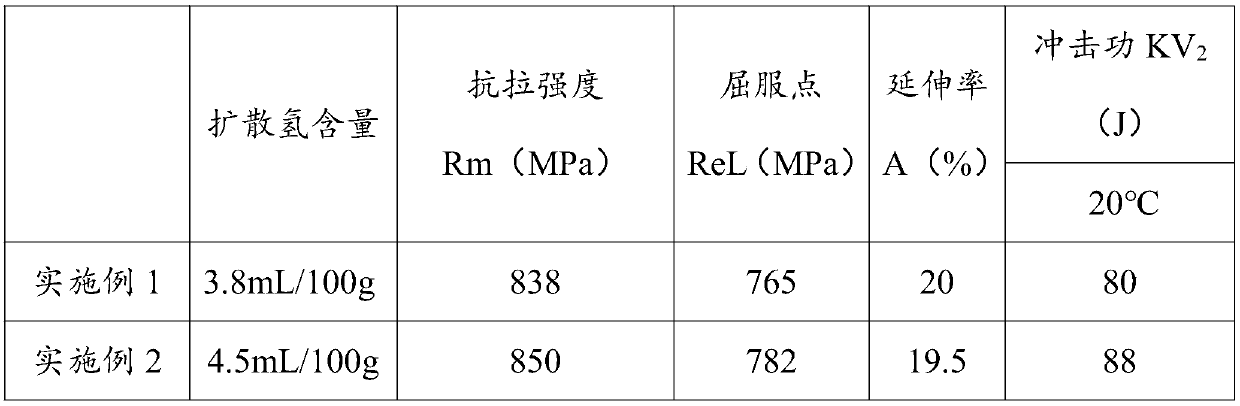

Embodiment 1

[0045] A 14mm×0.8mm (width×thickness) steel strip is used as the sheath of the welding wire, and its chemical composition includes C0.035wt%, Mn 0.23wt%, Si 0.015wt%, S 0.006wt%, P 0.009wt%, and the balance is Iron and inevitable impurities.

[0046] The weight of the flux core accounts for 15wt% of the weight of the entire welding wire. The contents of the components in the flux core are: rutile: 30kg, silicate minerals: 4kg, magnesium powder: 6kg, fluoride: 1kg, titanium iron: 1kg, molybdenum iron: 6kg , Nickel powder: 12kg, electrolytic manganese: 11kg, 75 ferrosilicon: 5kg, wollastonite: 7kg, iron powder 16.2kg.

[0047] After mixing the components of the flux core evenly, put the outer sheath in the welding wire forming machine, pour the flux core mixture to be used into the groove of the outer sheath that is bent horizontally into a "U" shape, and then roll it into a wire. , After fine drawing to Φ1.2mm, the rutile-type flux-cored welding wire with tensile strength of 8...

Embodiment 2

[0049] A 14mm×0.8mm (width×thickness) steel strip is used as the outer skin of the welding wire, and its chemical composition is C0.035wt%, Mn0.23wt%, Si 0.015wt%, S 0.006wt%, P 0.009wt%, and the balance is Iron and inevitable impurities.

[0050] The weight of the flux core accounts for 15wt% of the weight of the entire welding wire. The contents of each component in the flux core are: rutile: 30kg, silicate minerals: 5kg, magnesium powder: 6kg, fluoride: 1kg, ferrotitanium: 1kg, ferromolybdenum: 6kg , nickel powder: 11kg, electrolytic manganese: 13kg, 75 ferrosilicon: 5kg, wollastonite: 7kg, iron powder 14.2kg.

[0051] After mixing the components of the flux core evenly, put the outer sheath in the welding wire forming machine, pour the flux core mixture to be used into the groove of the outer sheath that is bent horizontally into a "U" shape, and then roll it into a wire. , After fine drawing to Φ1.6mm, the rutile flux-cored welding wire with tensile strength of 800MPa is...

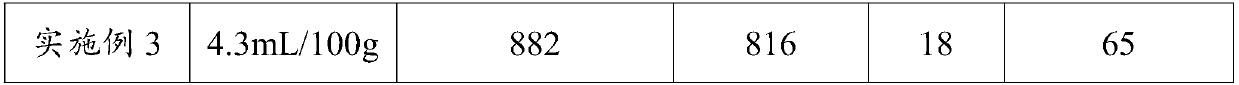

Embodiment 3

[0053] A 14mm×0.8mm (width×thickness) steel strip is used as the outer skin of the welding wire, and its chemical composition is C0.035wt%, Mn0.23wt%, Si 0.015wt%, S 0.006wt%, P 0.009wt%, and the balance is Iron and inevitable impurities.

[0054] The weight of the flux core accounts for 15wt% of the weight of the whole welding wire. The contents of each component in the flux core are: rutile: 30kg, silicate minerals: 6kg, magnesium powder: 6kg, fluoride: 1kg, ferrotitanium: 1kg, ferromolybdenum: 6kg , nickel powder: 10kg, electrolytic manganese: 15kg, 75 ferrosilicon: 5kg, wollastonite: 7kg, iron powder 12.2kg.

[0055] After mixing the components of the flux core evenly, put the outer sheath in the welding wire forming machine, pour the flux core mixture to be used into the groove of the outer sheath that is bent horizontally into a "U" shape, and then roll it into a wire. , After fine drawing to Φ2.0mm, the rutile flux-cored welding wire with tensile strength of 800MPa is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com