Molybdenum containing stainless steel welding rod steel and preparing method thereof

A technology of stainless steel and welding rod steel, which is applied in the direction of electric furnace, furnace, process efficiency improvement, etc. It can solve the problems of poor high-temperature plasticity, low yield, and poor surface quality of materials, achieve good drawing performance, overcome easy overacid, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Design principle of the present invention is as follows:

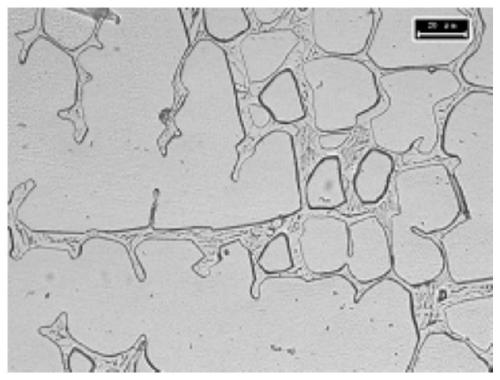

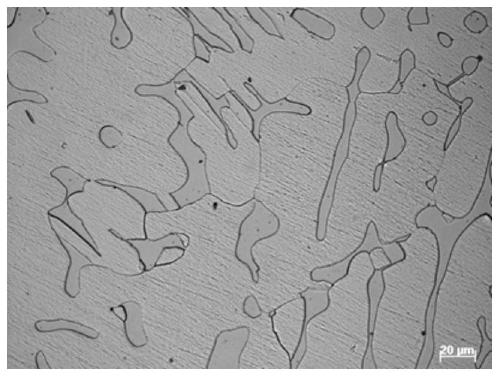

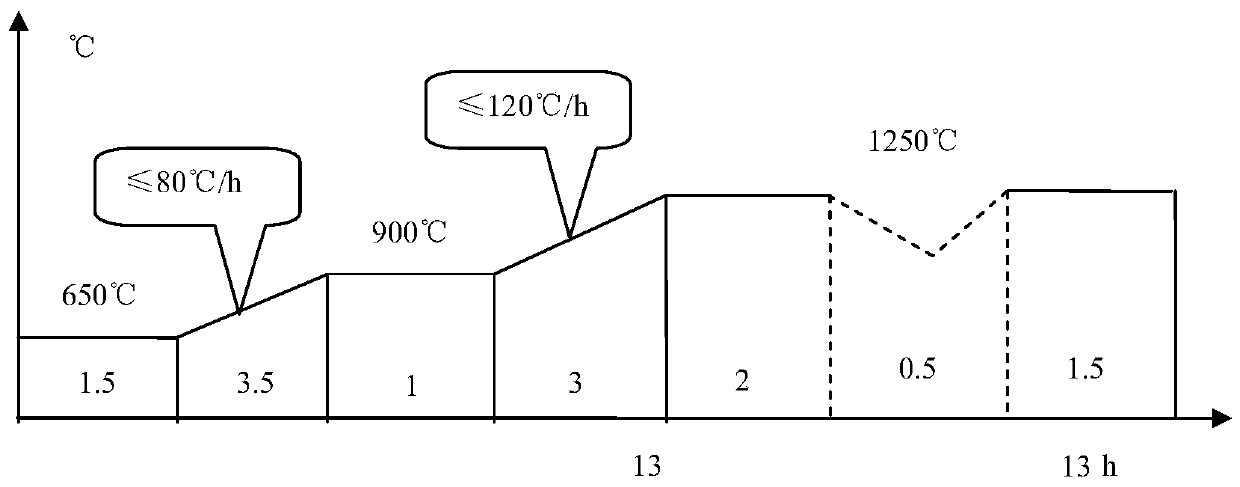

[0027] When the content of molybdenum is high, it is easy to produce 6 intermediate phases in austenitic stainless steel. 6 phases are a brittle and hard secondary phase. Chromium and molybdenum can improve the precipitation behavior of 6 phases at high temperatures, which is unfavorable to the mechanical properties of stainless steel. The influence of plasticity and toughness will decrease. Generally, the ferrite content of 309 is between 8% and 12%, and the ferrite content of 309Mo reaches about 25% (see figure 1 ), in the process of thermal deformation, the austenite and ferrite phases have obvious differences in strength due to the difference in lattice structure and solid solution elements. During thermal deformation, stress concentration is formed at the phase boundary between the two phases and cracks are likely to occur. The thermoplasticity of this steel is poor, and the deformation temperature range i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com