Preparation method of cold-rolled sheet for flux-cored wire

A technology of cold-rolled sheet and flux-cored wire, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of unstable performance, low elongation, high content of inclusion elements, etc., and achieve excellent cold forming performance and drawing performance , high tensile strength, low yield strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The invention provides a cold-rolled thin plate for flux-cored welding wire, the grade is HS1, and the chemical composition mass percentage of its steel is shown in Table 1:

[0063] Table 1 Example 1 adopts the chemical composition of billets

[0064] Grade

C

Si

mn

P

S

Alt

N

Fe

HS1

0.020

0.03

0.15

0.010

0.010

0.030

0.0030

the remaining

[0065] The preparation method of the cold-rolled sheet for the flux-cored welding wire comprises the following steps:

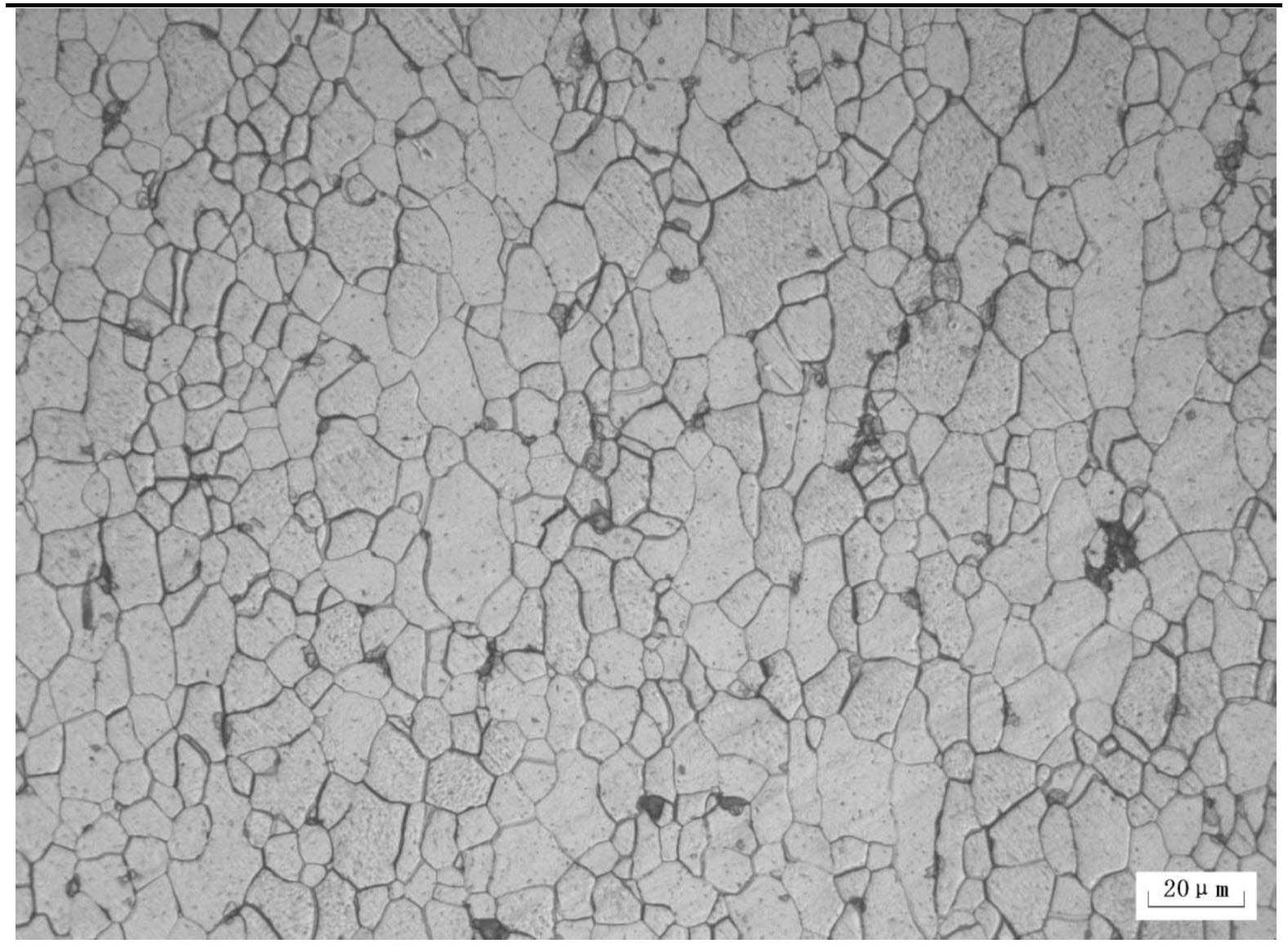

[0066] The steel billets whose chemical composition mass percentages are shown in Table 1 are sequentially hot-rolled, pickled, and cold-rolled to obtain cold-rolled steel coils, and then processed by continuous annealing and tempering.

[0067] Wherein, in the hot rolling step, the hot rolling process parameters of the billet are: the heating temperature is 1282°C, the final rolling temperature is 913°C, and...

Embodiment 2

[0080] The invention provides a cold-rolled thin plate for flux-cored welding wire, the grade is HS1, and the chemical composition mass percentage of its steel is shown in Table 2:

[0081] Table 2 Example 2 adopts the chemical composition of billets

[0082] Grade

C

Si

mn

P

S

Alt

N

Fe

HS1

0.020

0.03

0.15

0.010

0.010

0.030

0.0030

the remaining

[0083] The preparation method of the cold-rolled sheet for the flux-cored welding wire comprises the following steps:

[0084] The steel billets whose chemical composition mass percentages are shown in Table 2 are sequentially hot-rolled, pickled, and cold-rolled to obtain cold-rolled steel coils, and then processed by continuous annealing and tempering.

[0085] Wherein, in the hot rolling step, the hot rolling process parameters of the billet are: the heating temperature is 1293°C, the final rolling temperature is 992°C, and...

Embodiment 3

[0098] The invention provides a cold-rolled thin plate for flux-cored welding wire, the grade is HS2, and the chemical composition mass percentage of its steel is shown in Table 3:

[0099] Table 3 Example 3 adopts the chemical composition of billet

[0100] Grade

C

Si

mn

P

S

Alt

N

Fe

HS2

0.040

0.03

0.26

0.010

0.010

0.030

0.0030

the remaining

[0101] The preparation method of the cold-rolled sheet for the flux-cored welding wire comprises the following steps:

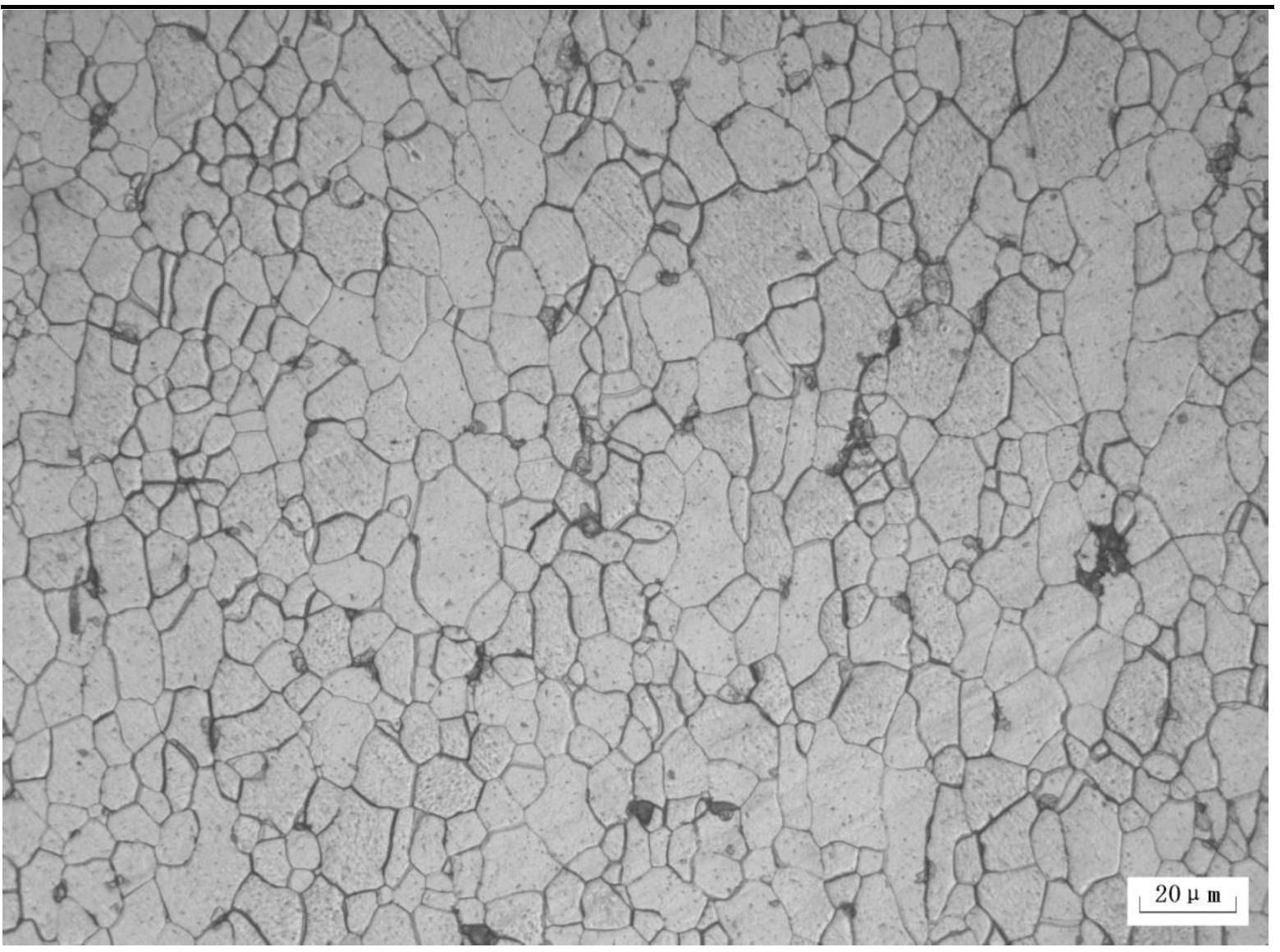

[0102] The steel billets whose chemical composition mass percentages are shown in Table 3 are sequentially hot-rolled, pickled, and cold-rolled to obtain cold-rolled steel coils, and then processed by continuous annealing and tempering.

[0103] Wherein, in the hot rolling step, the hot rolling process parameters of the billet are: the heating temperature is 1273°C, the final rolling temperature is 918°C, and ...

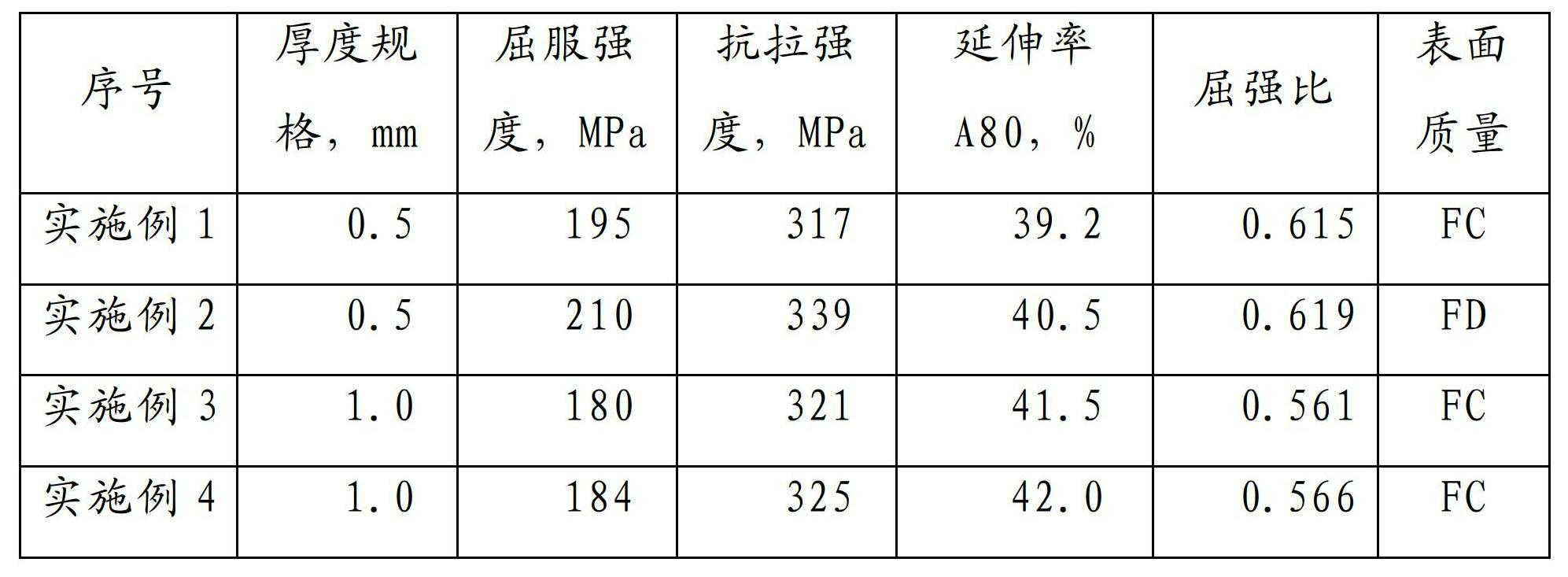

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com