Controlled rolling and controlled cooling method for reducing martensite in microstructure of high-alloy steel hot-rolled wire rod

A hot-rolled wire rod and high-alloy steel technology, applied in the field of steel rolling, can solve the problems of brittle fracture and scrapping of the whole coil, so as to reduce the scrap rate and avoid brittle fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

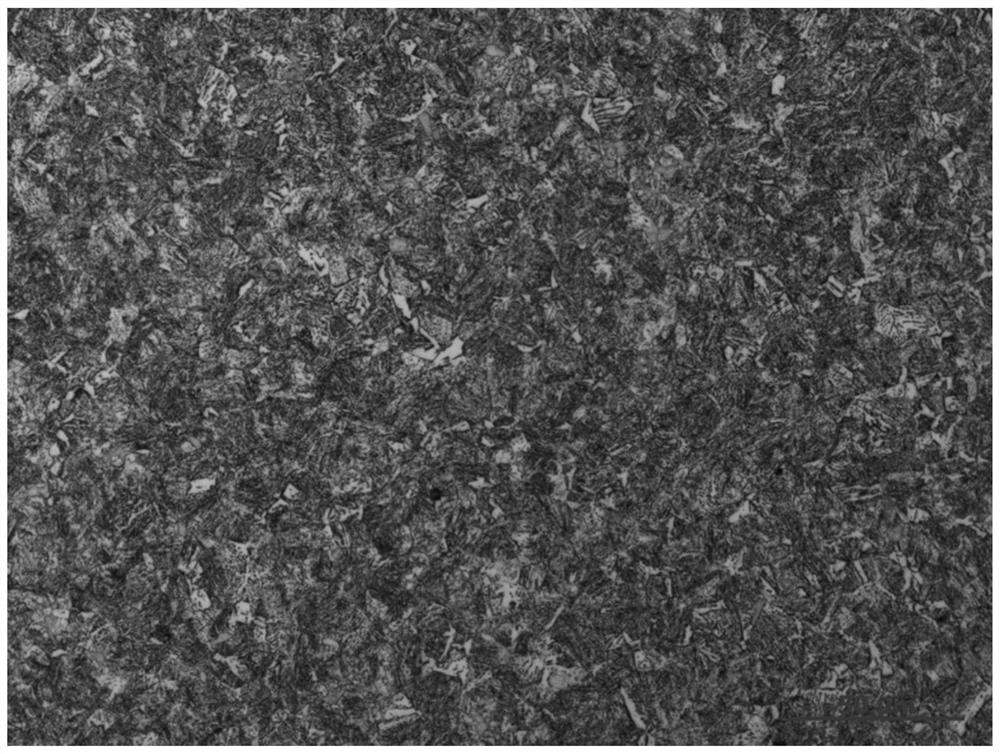

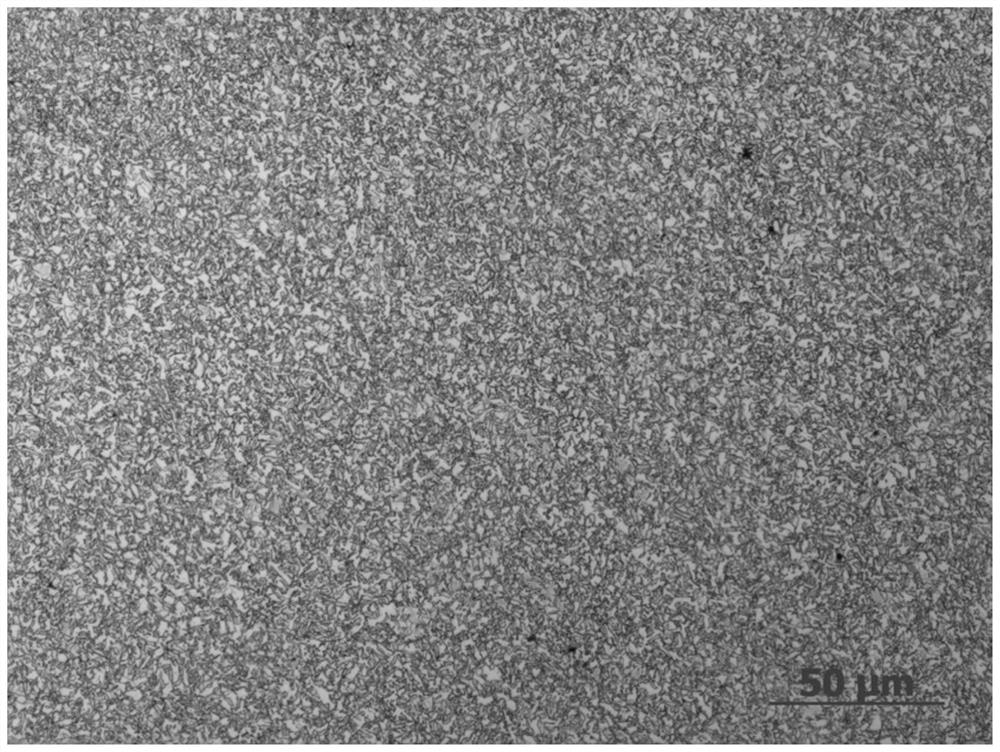

Embodiment 1

[0037] 1. Billet heating

[0038] Rolling composition C: 0.21%, Si: 0.28%, Mn: 1.12%, P: 0.008%, S: 0.004%, Cr: 0.66%, Ni: 0.77%, Cu: 0.02%, Al: 0.034%, Mo: 0.28%.

[0039] Heat the steel billet with a cross-section of 160mm×160mm in the temperature environment of 700-800°C for 40 minutes in the first section of the regenerative heating furnace, heat it in the temperature environment of 900-1000°C in the second section for 40 minutes, and heat it in the temperature environment of 1040-1100°C in the soaking section Heat in medium for 50min.

[0040] 2. Controlled rolling

[0041] After the billet comes out of the heating furnace, it undergoes rough rolling and pre-finishing deformation respectively at 900-1000°C. By adjusting the water flow of the water tank, the temperature of the billet reaching the finishing mill is controlled at 750-800°C. By turning on the cooling water between the stands, the The final rolling temperature of the finishing mill shall not exceed 820°C. ...

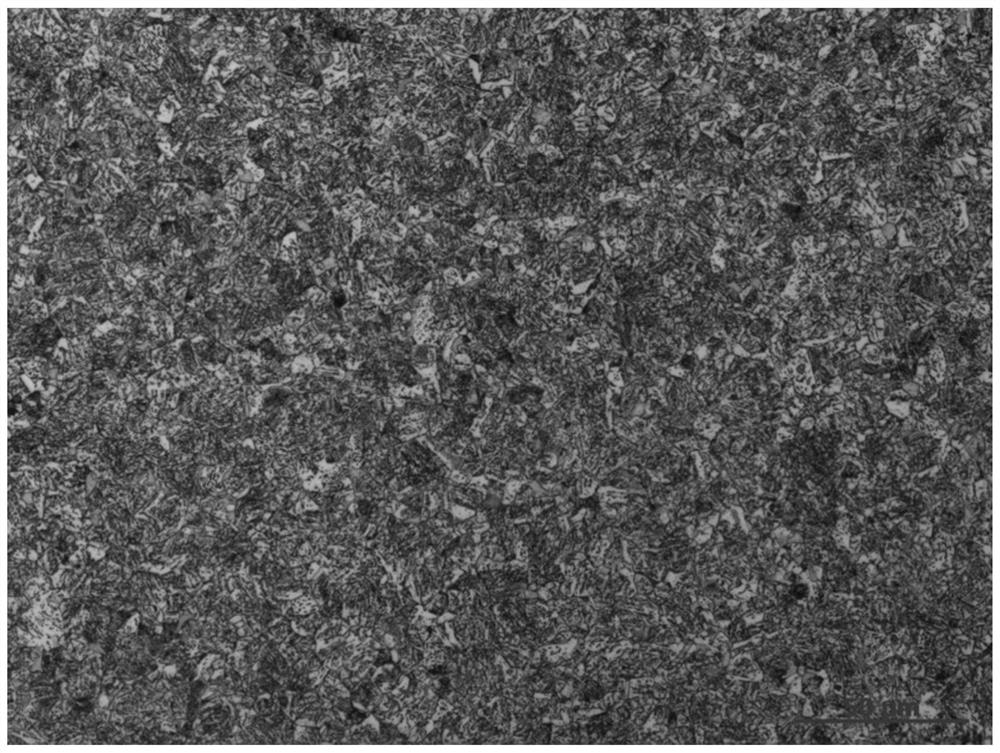

Embodiment 2

[0048] 1. Billet heating

[0049] Rolling composition C: 0.66%, Si: 1.12%, Mn: 0.54%, P: 0.005%, S: 0.002%, Cr: 0.37%, Ni: 0.28%, Cu: 0.01%, Al: 0.027%, Mo: 0.46%, V: 0.23%, Nb: 0.15%.

[0050] Heat the steel billet with a cross-section of 160mm×160mm in the temperature environment of 700-800°C for 40 minutes in the first section of the regenerative heating furnace, heat it in the temperature environment of 900-1000°C in the second section for 40 minutes, and heat it in the temperature environment of 1040-1100°C in the soaking section Heat in medium for 50min.

[0051] 2. Controlled rolling

[0052] After the billet comes out of the heating furnace, it undergoes rough rolling and pre-finishing deformation respectively at 900-1000°C. By adjusting the water flow of the water tank, the temperature of the billet reaching the finishing mill is controlled at 750-800°C. By turning on the cooling water between the stands, the The final rolling temperature of the finishing mill shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com