Spheroidizing annealing method for low-alloy high-strength welding wire

A low-alloy, high-strength, annealing technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of plasticity decrease, work hardening index increase, etc., and achieve the effect of plasticity increase and good drawing process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The ER80S-G welding wire is used as the raw material, and the method of the present invention is used for annealing treatment, and the actual effect is judged by the metallographic structure before and after annealing and whether the wire is smooth and broken during the drawing process. Determine its A by the thermal expansion method C1 The point is 740°C. The specific steps are:

[0036] 1) Use a bell-type atmosphere protection furnace to heat the ER80S-G welding wire to 690~710°C for 12 hours;

[0037] 2) Cool the ER80S-G welding wire in step 1) to 160°C with the furnace, then air cool to room temperature to complete the annealing operation.

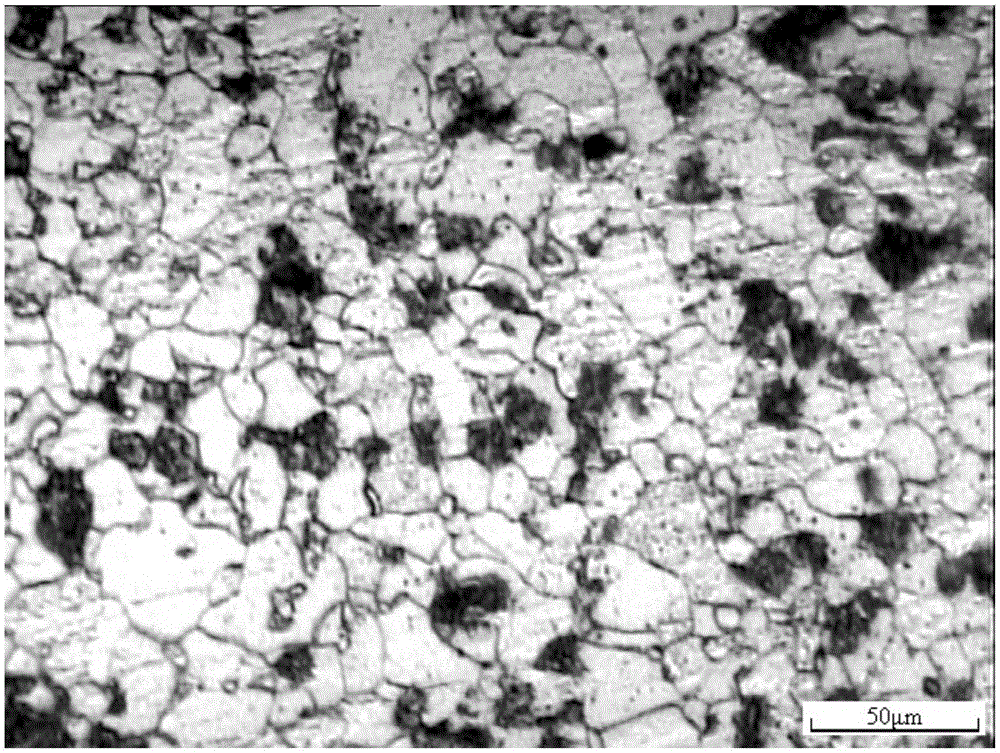

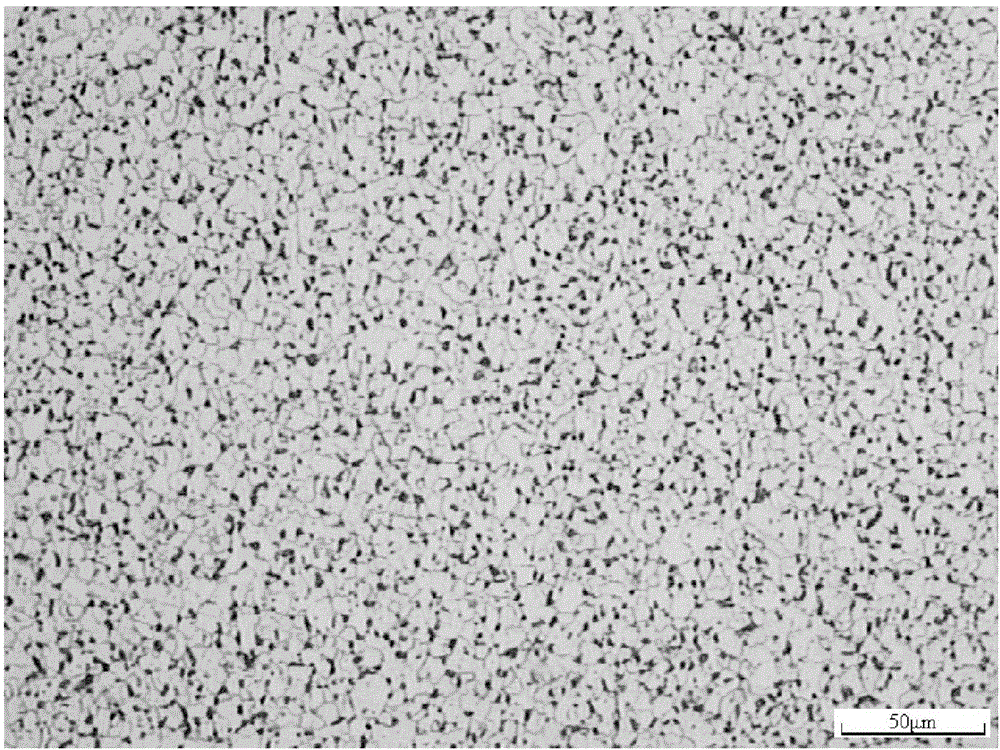

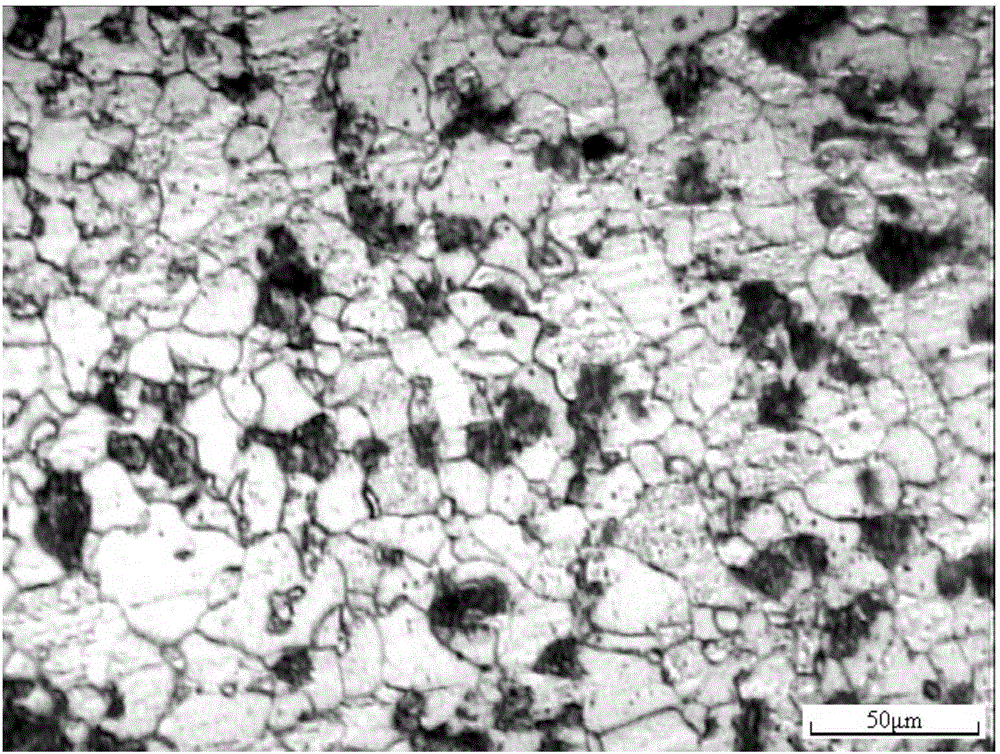

[0038] Figure 1-A It is the metallographic diagram of unannealed welding wire. The structure is ferrite, dispersed carbide and discontinuously distributed island-shaped bainite. The welding wire has high strength and hardness and poor plasticity. Figure 1-B It is the metallographic diagram of the welding wire after recrysta...

Embodiment 2

[0041] Using 76-G welding wire as raw material, the method of the present invention is used for annealing treatment, the actual effect is judged by the metallographic structure before and after annealing and whether the drawing process is smooth and broken wire, and the A C1 The point is 730°C. The specific steps are:

[0042] 1) Use a bell-type atmosphere protection furnace to heat the 76-G welding wire to 680~700°C for 14 hours;

[0043] 2) After cooling the 76-G welding wire in step 1) to 180°C with the furnace, air-cool to room temperature to complete the annealing operation.

[0044] Figure 2-A It is the metallographic diagram of unannealed welding wire. The structure is ferrite, dispersed carbide and discontinuously distributed island-shaped bainite. The welding wire has high strength and hardness and poor plasticity. Figure 2-B It is the metallographic diagram of the welding wire after recrystallization annealing. The structure is ferrite and fine spherical carbide...

Embodiment 3

[0047] Using SMHG-700 welding wire as raw material, the method of the present invention is used for annealing treatment, the actual effect is judged by the metallographic structure before and after annealing and whether the drawing process is smooth and broken wire, and the A C1 The point is 710°C. The specific steps are:

[0048] 1) Heat the SMHG-700 welding wire to 660~680°C for 14 hours in a bell-type atmosphere protection furnace;

[0049] 2) Cool the SMHG-700 welding wire in step 1) to 180°C with the furnace, then air cool to room temperature to complete the annealing operation.

[0050] Figure 3-A It is the metallographic diagram of unannealed welding wire. The structure is a small amount of ferrite, discontinuously distributed island-shaped bainite and dispersed carbide. The welding wire has high strength and hardness, and poor plasticity and toughness. Figure 3-B It is the metallographic diagram of the welding wire after recrystallization annealing. The structure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com