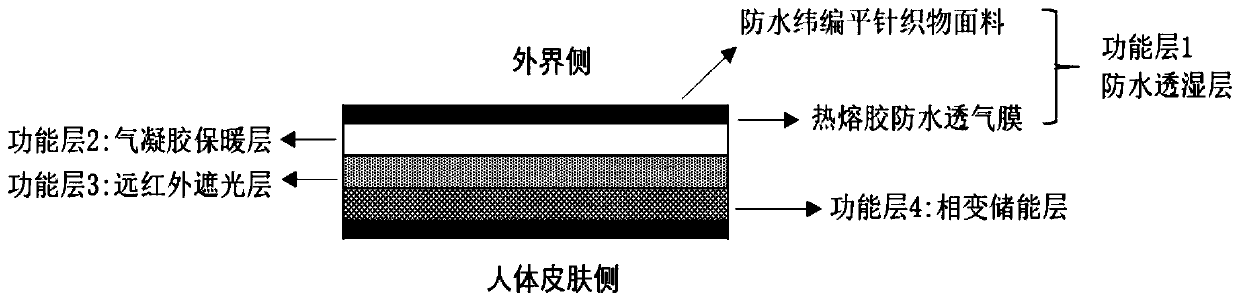

Aerogel based high-heat retention textile composite and preparation method thereof

An airgel thermal insulation layer and composite material technology, applied in the field of textile materials, can solve the problems of large thermal radiation heat loss, airgel powder loss, three-dimensional space structure damage, etc., to achieve good warmth retention, washability, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

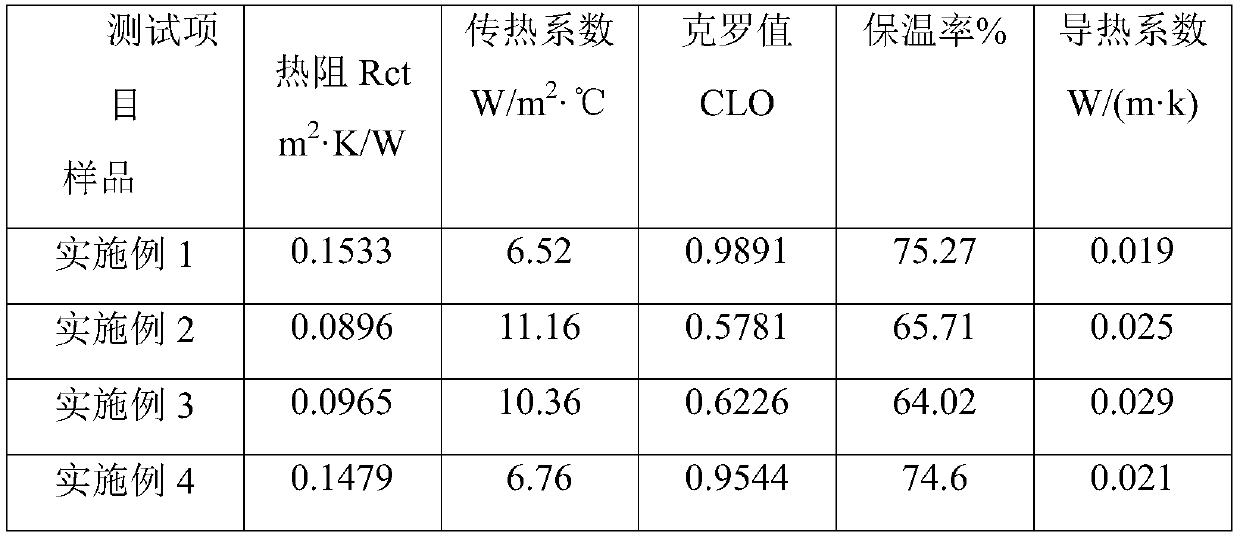

Embodiment 1

[0054] a. Finishing process of waterproof weft-knitted jersey fabric:

[0055] 2% TG-5671, padding liquid rate 60%, setting machine temperature 160 ℃, setting time 60s.

[0056] b. Hydrophobic airgel powder preparation:

[0057] Use methyltrimethoxysilane as the silicon source, mix it with isopropanol at a ratio of 1:4, stir vigorously at 30°C, then add deionized water and oxalic acid or hydrochloric acid as an acid catalyst, and stir for 1.5h to make The silicon source is fully hydrolyzed under acidic conditions, and the methoxyl group is hydrolyzed into hydroxyl groups. The above reaction process is maintained in a water bath at 30°C; then ammonia water is added dropwise to adjust the pH of the system to 8, and stirred for 10 minutes, and then the temperature of the water bath is adjusted to 40°C. Insulation for 3 hours, under the action of alkali catalysis, condensation reactions will occur between the hydroxyl groups produced by the hydrolysis of the silicon source and th...

Embodiment 2

[0067] a. Outer waterproof fabric finishing process:

[0068] 1% TG-5671, padding liquid rate 60%, setting machine temperature 150 ℃, setting time 60s.

[0069] b. Hydrophobic airgel powder preparation:

[0070] The preparation and grinding process of the airgel are the same as in Example 1, and the parameters are slightly changed, mainly including the molar ratio of silicon source to isopropanol 1:2, after the system conditions, the gel is incubated at 40°C for 4h, and the aging at 60°C for 36h, The drying time of each stage under normal pressure is 1h.

[0071] c. Phase change material microcapsule preparation:

[0072] The preparation of the microcapsules is the same as in Example 1, and the process parameters are slightly changed mainly including: the core material is selected from n-octadecane, the mass ratio of the core material to the capsule wall is 1:3, and the emulsifier selected when the core material is emulsified is polyvinylpyrrolidone , the dosage is 1.5%, an...

Embodiment 3

[0080] a. Outer waterproof fabric finishing process:

[0081] 1% TG-5671, padding liquid rate 60%, setting machine temperature 150 ℃, setting time 60s.

[0082] b. Hydrophobic airgel powder preparation:

[0083] The preparation and grinding process of the airgel are the same as in Example 1. The parameters are slightly changed, mainly including the molar ratio of silicon source to isopropanol 1:3, after the system conditions, the gel is incubated at 40°C for 3h, and the aging at 60°C for 48h, The drying time at each level of temperature under normal pressure is 2h.

[0084] c. Phase change material microcapsule preparation:

[0085] The preparation of the microcapsules is the same as in Example 1, and the process parameters are slightly changed mainly including: the core material is selected from the compound of n-17 and n-eicosane at 1:1, the mass ratio of the core material to the capsule wall is 1:2, and the core material is emulsified The selected emulsifier is the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com