Nanometer silicon carbide coated lithium nickel manganese cobalt cathode material and preparation method thereof

A technology of nickel-cobalt lithium manganate and nano-silicon carbide, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Rate capability and cycling capability, simple operation, and the effect of reducing surface polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a kind of nano-silicon carbide coated nickel-cobalt lithium manganese oxide positive electrode material, and its preparation method comprises the following steps:

[0033] (a) Precursor (Ni 0.5 co 0.2 mn 0.3 )OH 2 Li:Ni 0.5 co 0.2 mn 0.3 =1.04:1 molar ratio using dry mixing method for uniform mixing; then packed into a sagger for compaction, sintered at a constant temperature of 910°C in an air atmosphere for 12h, naturally cooled to below 80°C after completion, coarsely broken, Finely crushing and sieving to obtain the nickel-cobalt-lithium-manganese-oxide positive electrode material;

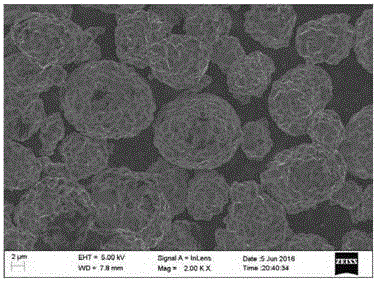

[0034] (b) Put the above-mentioned nickel-cobalt lithium manganese oxide positive electrode material and nano-silicon carbide (primary particle size is 10-100nm) at a mass ratio of 1000:4, and put them into a ball mill tank lined with polytetrafluoroethylene (using oxidation Zirconium balls are mixed and coated by dry ball milling at a speed of 200 rpm fo...

Embodiment 2

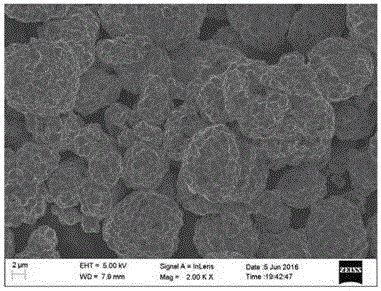

[0036] This embodiment provides a nano-silicon carbide-coated nickel-cobalt-lithium-manganese-oxide positive electrode material. Its preparation method is basically the same as that in Example 1, except that different nano-silicon carbides are used, and the primary particle size is 100-400nm, the sample number is SY523C-2, such as image 3 shown.

Embodiment 3

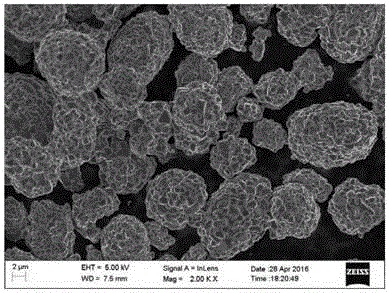

[0038]This embodiment provides a nano-silicon carbide-coated nickel-cobalt lithium manganese oxide positive electrode material. Its preparation method is basically the same as that in Example 1, except that the nickel-cobalt lithium manganese oxide prepared by sintering is LiNi 0.6 co 0.2 mn 0.2 o 2 ; In step (b), sintering at 800°C for 8h in an air atmosphere to obtain LiNi coated with nano-silicon carbide 0.6 co 0.2 mn 0.2 o 2 Sample SY622C-3, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com