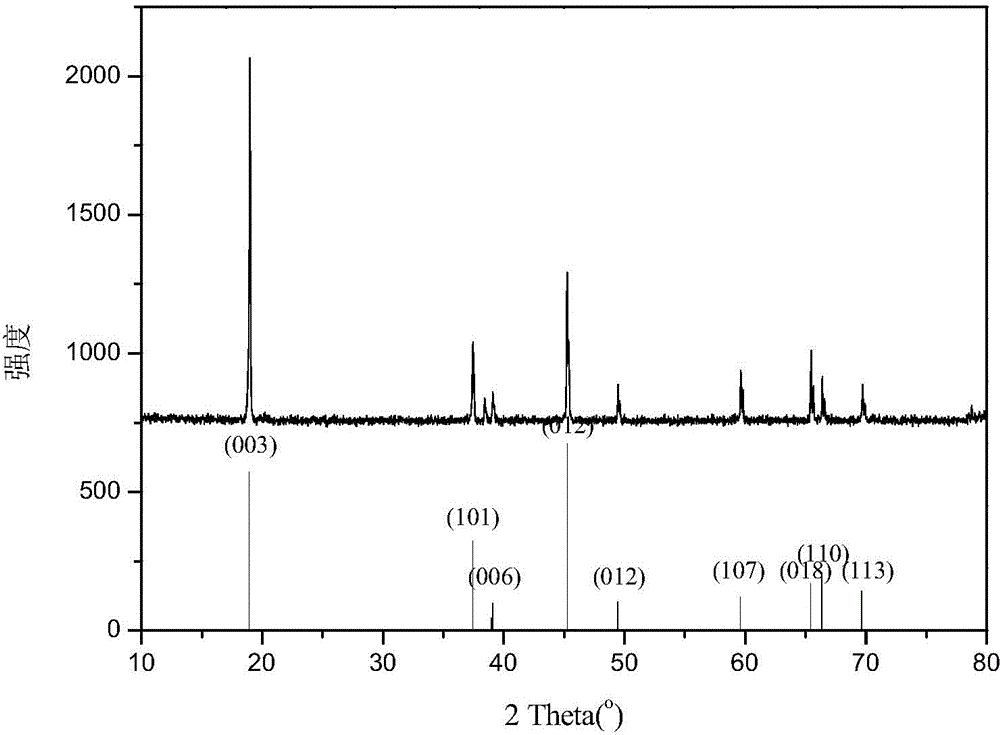

Surface-modified lithium cobaltate material and preparation method thereof

A surface modification, lithium cobalt oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of not meeting the sample performance, reducing the energy density of lithium-ion batteries, and not improving the material discharge specific capacity and first efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is a method for preparing a surface-modified lithium cobaltate material, comprising the following steps:

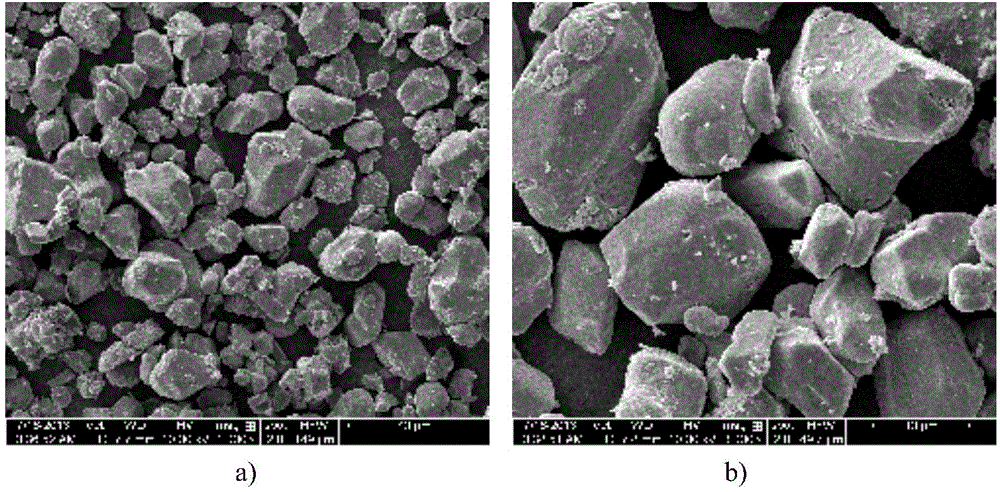

[0041] (1) Lithium carbonate, cobalt tetroxide, cobalt acetate, and magnesium oxide are ball-milled and mixed in a dry method at a molar ratio of 1.20:0.98:0.02 for lithium, cobalt, and magnesium; Roasting in air atmosphere and under normal pressure at 600°C for 13 hours to obtain magnesium-doped single crystal lithium cobaltate; the roasted material is coarsely crushed and then crushed and sieved by jet mill to finally obtain lithium cobaltate to be coated material, its average particle size D 50 is 6 microns.

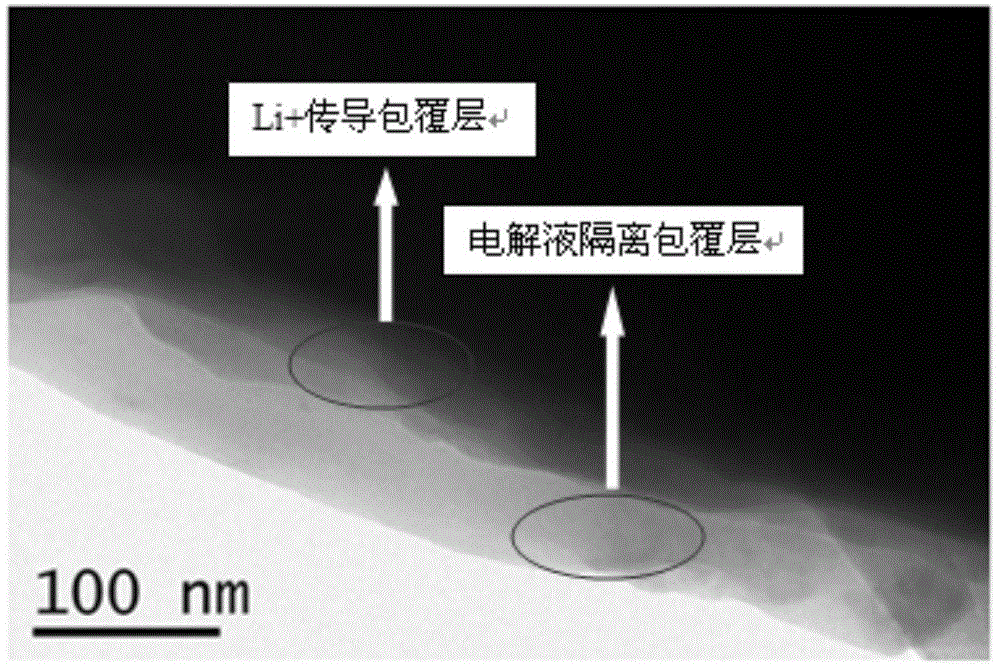

[0042] (2) Add nickel acetate to ethanol, wherein the mass ratio of nickel acetate to ethanol is 1:100, stir for 4 hours, add lithium cobaltate obtained in step (1) to the above mixed solution, and heat at 300°C The first layer of coating on lithium cobaltate was preliminarily completed after drying for 2 hours. The thickness of the coati...

Embodiment 2

[0046] This embodiment is a preparation method of a surface-modified lithium cobaltate material, and the specific steps are as follows:

[0047] (1) Lithium hydroxide, cobalt hydroxide, tetrabutyl titanate, and aluminum oxide are mixed by ball milling in a dry method according to the ratio of lithium, cobalt, titanium, and aluminum in a molar ratio of 1.07:0.98:0.01:0.01; the mixing is completed Finally, the above materials are placed in a roasting furnace and roasted in an air atmosphere and under normal pressure at 1000°C for 13 hours to obtain titanium-aluminum-doped single crystal lithium cobaltate. The roasted materials are coarsely crushed and then crushed by a jet mill Sieve to finally obtain the lithium cobaltate material to be coated, its average particle size D 50 about 20 microns.

[0048](2) Add manganese acetate and cobalt acetate to deionized water, wherein the mass ratio of the sum of the mass of manganese acetate and cobalt acetate to deionized water is 1:5, s...

Embodiment 3

[0052] This embodiment is a preparation method of a surface-modified lithium cobaltate material, and the specific steps are as follows:

[0053] (1) Lithium carbonate, cobalt tetroxide, magnesium oxide and titanium dioxide are mixed by ball milling in a dry method according to the molar ratio of lithium, cobalt, magnesium and titanium at a molar ratio of 1.06:0.96:0.02:0.02; Roasting in the furnace in the air atmosphere and under normal pressure at 1015°C for 13 hours; the roasted material is coarsely crushed and then crushed and sieved by a jet mill to finally obtain the magnesium-titanium-doped single crystal lithium cobaltate to be coated material, its average particle size D 50 About 16 microns.

[0054] (2) Add cobalt acetate to the de-ethanol, wherein the mass ratio of cobalt acetate to ethanol is 1:50, stir for 1 hour, and add the single crystal lithium cobaltate doped with magnesium and titanium obtained in step (1) to the above mixed solution and dry at 200°C for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com