Lithium-rich manganese-based positive electrode material coated with double conductive layers as well as preparation method and application thereof

A lithium-rich manganese-based, cathode material technology, applied in the field of materials, can solve problems such as unfavorable cycle capacity retention, unsustainable capacity provision, and rapid cycle loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

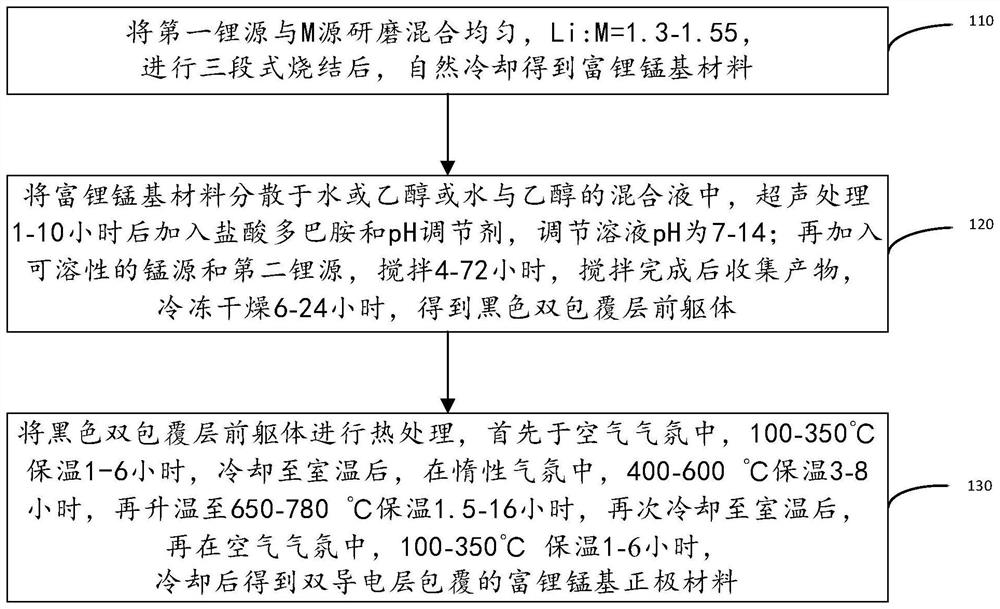

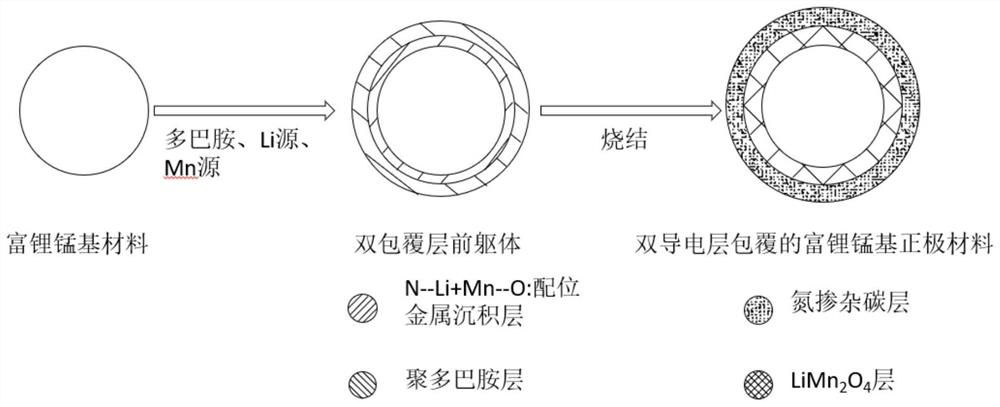

[0050] The preparation process proposed above has low complexity, the uniformity and completeness of the double-layer coating of the material can be controlled, and it is easy to realize industrial mass production.

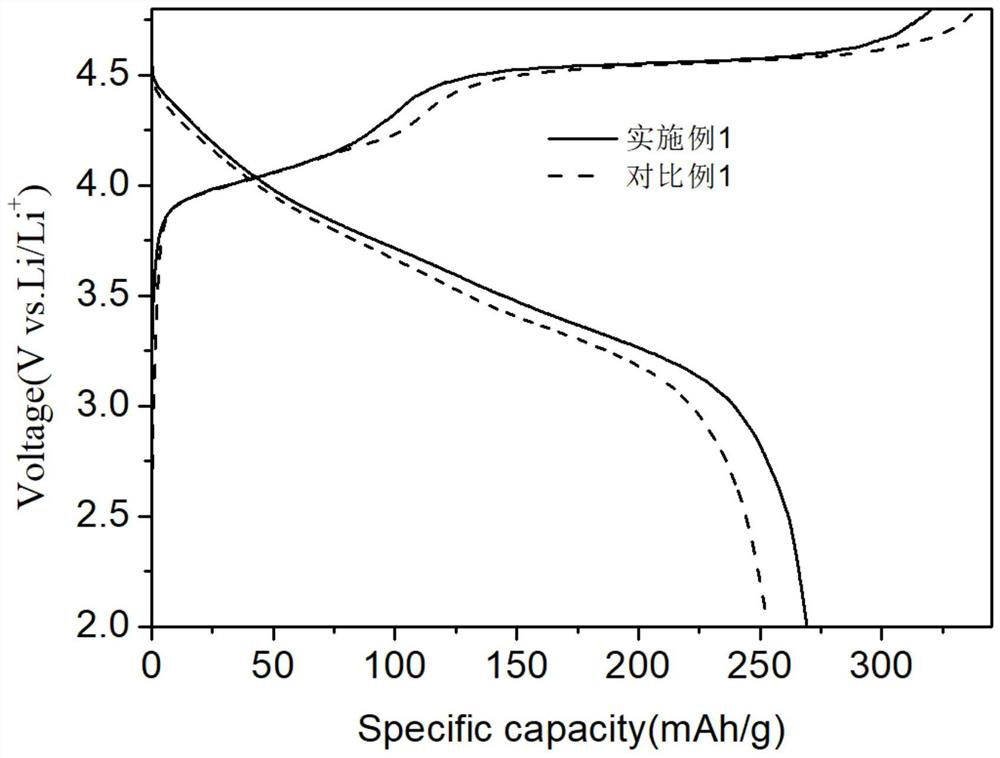

[0051] In order to better understand the technical solution provided by the present invention, the following specific examples are used to illustrate the specific process of applying the several methods provided by the above-mentioned embodiments of the present invention to prepare the lithium-rich manganese-based lithium battery cathode material coated with double conductive layers , and its properties.

Embodiment 1

[0053] Step 1, take an appropriate amount of manganese-rich ternary carbonate precursor Ni 0.16 co 0.16 mn 0.68 CO 3 , weigh LiOH according to Li:M=1.55, grind and mix evenly, and carry out three-stage sintering. First, heat at 350°C in air for 2 hours, then heat up to 500°C for 5 hours, and finally heat up to 750°C for 6 hours, and then After natural cooling, a lithium-rich manganese-based material is obtained. Wherein, the heating rate of each stage is 5°C / min.

[0054] Step 2, disperse 880 g of the obtained lithium-rich manganese-based material in 1 L of water, ultrasonicate for 6 hours, then add 9.45 g of dopamine hydrochloride, then add 2.6 g of potassium permanganate and 0.55 g of lithium acetate, and finally add tris ( Tirs) buffer to adjust the pH to 8.5 and stir for 16 hours. After the stirring was completed, the product was collected and freeze-dried for 6 hours to obtain a black double-coated precursor.

[0055] Step 3, the black double-coated layer precursor ...

Embodiment 2

[0063] Step 1, take an appropriate amount of manganese-rich ternary carbonate precursor Ni 0.16 co 0.16 mn 0.68 CO 3 , weigh LiOH according to Li:M=1.65, grind and mix evenly, carry out three-stage sintering, keep warm at 380°C in the air for 7 hours, then heat up to 550°C for 8 hours, and finally heat up to 800°C for 6 hours, and then wait for Lithium-rich manganese-based materials were obtained by natural cooling. Wherein, the heating rate of each stage is 5°C / min.

[0064] Step 2, disperse 880 g of the obtained lithium-rich manganese-based material in 1 L of water, ultrasonicate for 6 hours, add 4.72 g of dopamine hydrochloride, then add 1.58 g of potassium permanganate and 0.28 g of lithium acetate, and finally add Tirs buffer to adjust the pH to 8.5, Stir for 36 hours. After the stirring was completed, the product was collected and freeze-dried for 8 hours to obtain a black double-coated precursor.

[0065] Step 3, the black double-coated layer precursor is firstly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com