Positive electrode active material, preparation method thereof and lithium battery

A positive electrode active material and lithium ion technology, which is applied in the field of positive electrode active material and its preparation and lithium battery, can solve the problems such as the limited effect of improving the stability of lithium nickel manganese oxide material, so as to improve the cycle stability performance and Coulomb efficiency, and improve the stability properties, the effect of inhibiting the dissolution of manganese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 18g of LiNi 0.5 mn 1.5 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54g CuO and 0.267g (NH 4 ) 2 HPO 4 Mix evenly, and calcinate the obtained mixture in oxygen at 600° C. for 5 h, with a heating rate of 3° C. / min and a cooling rate of 5° C. / min.

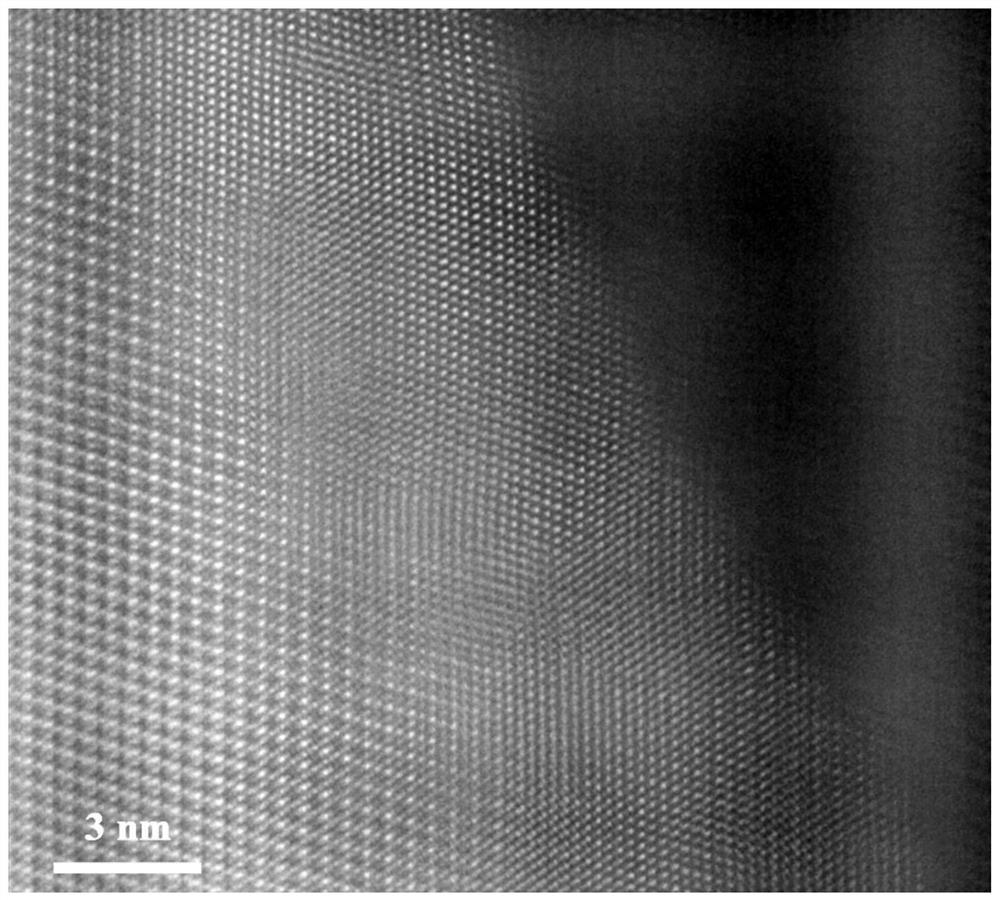

[0047] figure 1 LiNi after showing the phosphorus element doping that embodiment 1 makes 0.5 mn 1.5 o 4 STEM map. From figure 1 Phosphorus doped LiNi 0.5 mn 1.5 o 4 It can be seen from the STEM image that there is a rock-salt-like phase generated by the occupation of 16c atoms of spinel octahedron on the surface of the material, and the thickness of the rock-salt-like phase on the surface is about 12nm.

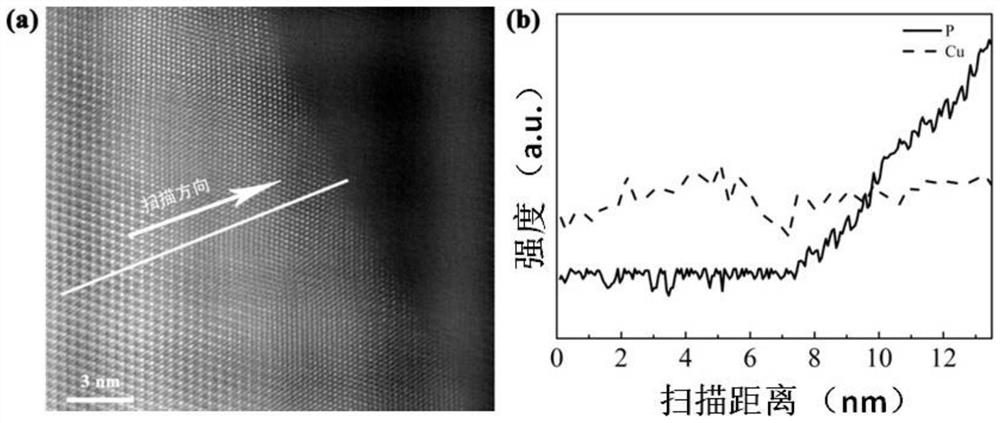

[0048] figure 2 (a) and (b) are LiNi after phosphorus element doping that embodiment 1 makes 0.5 mn 1.5 o 4 STEM line scan of the surface, from figure 2 It can be seen that the surface of lithium nickel manganese oxide after doping is still a typical spinel structure of lithium nickel man...

Embodiment 2

[0050] 18g of LiNi 0.4 mn 1.6 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54g H 3 PO 4 Mix evenly with 1 g of oxalic acid, and calcinate the resulting mixture in oxygen at 600° C. for 5 h, with a heating rate of 3° C. / min and a cooling rate of 5° C. / min.

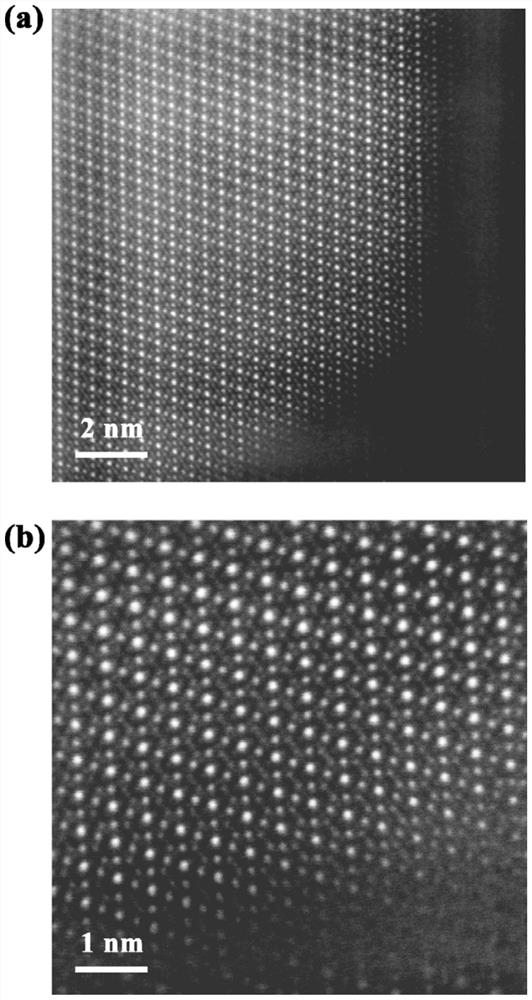

[0051] image 3 LiNi after showing the phosphorus element doping that embodiment 2 makes 0.4 mn 1.6 o 4 STEM images of , where (a) and (b) are images at different magnifications, respectively. From image 3 Phosphorus doped LiNi 0.4 mn 1.6 o 4 It can be seen from the STEM image that there is a rock-salt phase occupying the spinel octahedron 8a atoms on the surface of the material, and the thickness of the surface rock-salt phase is about 10nm.

[0052] Figure 4 LiNi after showing the phosphorus element doping that embodiment 2 makes 0.4 mn 1.6 o 4 The relative content of phosphorus on the surface was characterized by XPS at different etching depths. We can see that the content of phosphorus ...

Embodiment 3

[0054] 18g of LiNi 0.5 mn 1.5 o 4 Material (Shandong Qixing Energy Materials Co., Ltd.), 0.54g Cr 2 o 3 and 0.267g (NH 4 ) 2 HPO 4 and 20ml of deionized water were added into a beaker and mixed evenly, and the beaker was placed in an oil bath at 120° C. and heated with stirring for 5 hours to obtain a dry mixture. The resulting mixture was calcined in air at 725°C for 5h, with a heating rate of 3°C / min and a cooling rate of 5°C / min.

[0055] Figure 5 LiNi after showing the phosphorus element doping that embodiment 3 makes 0.5 mn 1.5 o4 STEM map. From Figure 5 Phosphorus doped LiNi 0.5 mn 1.5 o 4 It can be seen from the STEM image that there are rock-salt-like phases occupying 2-3nm spinel octahedral 8a and 16c atoms on the surface of the material, and the thickness of the rock-salt-like phase on the surface is about 2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com