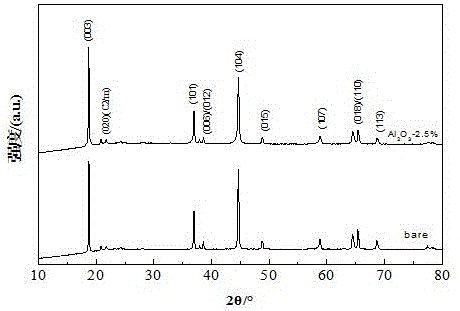

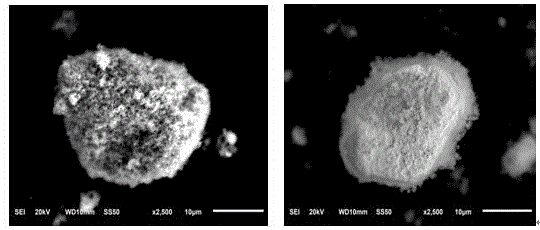

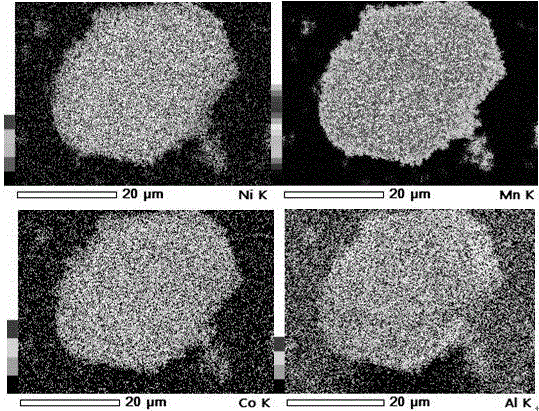

Modifying method by coating surface of lithium-rich positive electrode material with alumina

A lithium-rich cathode material and surface coating technology, which is applied to battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of low coulombic efficiency in the first cycle, affecting the performance of cathode materials, and uneven distribution of coating layers. Achieve the effects of simple process, inhibition of metal ion dissolution, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Lithium-rich cathode material xLi 2 MnO 3 ·(1-x)LiNi 0.5 co 0.3 mn 0.2 o 2 The preparation steps are as follows:

[0040](1) Weigh 5.257 g NiSO4·H2O, 3.3732 g CoSO4·H2O, 11.4933 g MnSO4·H2O, configure into 50 mL mixed solution, stir with a glass rod until all metal salts are dissolved, weigh 2 g ammonia water (mass fraction 28%) As a complexing buffer, add the metal salt solution configured above, weigh 8 g NaOH as a precipitant, and configure it into a 50 mL solution, stir with a glass rod until the NaOH is completely dissolved;

[0041] (2) Before starting the reaction, add 100 mL of deionized water to a four-hole flask with a capacity of 500 mL, then add an appropriate amount of ammonia water with a mass fraction of 28%, and control the pH at 11.0±0.1;

[0042] (3) After the reaction started, the temperature of the reaction system was controlled at 50 °C, and the stirring intensity was 700 r / min. The metal ion solution and the precipitant were fed into the reac...

Embodiment 2

[0053] Lithium-rich cathode material xLi 2 MnO 3 ·(1-x)LiNi 0.5 co 0.3 mn 0.2 o 2 The preparation steps are as follows:

[0054] (1) Weigh 7.8855 g NiSO4·H2O, 5.0598 g CoSO4·H2O, 8.7890 g MnSO4·H2O, configure into 50 mL mixed solution, stir with a glass rod until all metal salts are dissolved, weigh 2 g ammonia water (mass fraction 28%) As a complexing buffer, add the metal salt solution configured above, weigh 8 g NaOH as a precipitant, and configure it into a 50 mL solution, stir with a glass rod until the NaOH is completely dissolved;

[0055] (2) Before starting the reaction, add 100 mL of deionized water to a four-hole flask with a capacity of 500 mL, then add an appropriate amount of ammonia water with a mass fraction of 28%, and control the pH at 11.0±0.1;

[0056] (3) After the reaction started, the temperature of the reaction system was controlled at 50 °C, and the stirring intensity was 700 r / min. The metal ion solution and the precipitant were fed into the rea...

Embodiment 3

[0067] Lithium-rich cathode material xLi 2 MnO 3 ·(1-x)LiNi 0.5 co 0.3 mn 0.2 o 2 The preparation steps are as follows:

[0068] (1) Weigh 6.5713 g NiSO4·H2O, 7.0275 g CoSO4·H2O, 10.1412 g MnSO4·H2O, configure into 50 mL mixed solution, stir with a glass rod until all metal salts are dissolved, weigh 2 g of ammonia water (mass fraction 28%) As a complexing buffer, add the metal salt solution configured above, weigh 8 g NaOH as a precipitant, and configure it into a 50 mL solution, stir with a glass rod until the NaOH is completely dissolved;

[0069] (2) Before starting the reaction, add 100 mL of deionized water to a four-hole flask with a capacity of 500 mL, then add an appropriate amount of ammonia water with a mass fraction of 28%, and control the pH at 11.0±0.1;

[0070] (3) After the reaction started, the temperature of the reaction system was controlled at 50 °C, and the stirring intensity was 700 r / min. The metal ion solution and the precipitant were fed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com