Lithium-sulfur battery cathode material, preparation method, and lithium-sulfur battery

A cathode material, lithium-sulfur battery technology, applied in the field of lithium-sulfur battery cathode materials, lithium-sulfur battery materials, preparation, can solve the problem of reducing the electrochemical activity of the sulfur electrode conductivity, reducing the discharge capacity of the sulfur cathode, and the limited effect of coating, etc. problems, to achieve the effect of accelerating the electrode reaction kinetics, inhibiting the shuttle effect, and facilitating penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

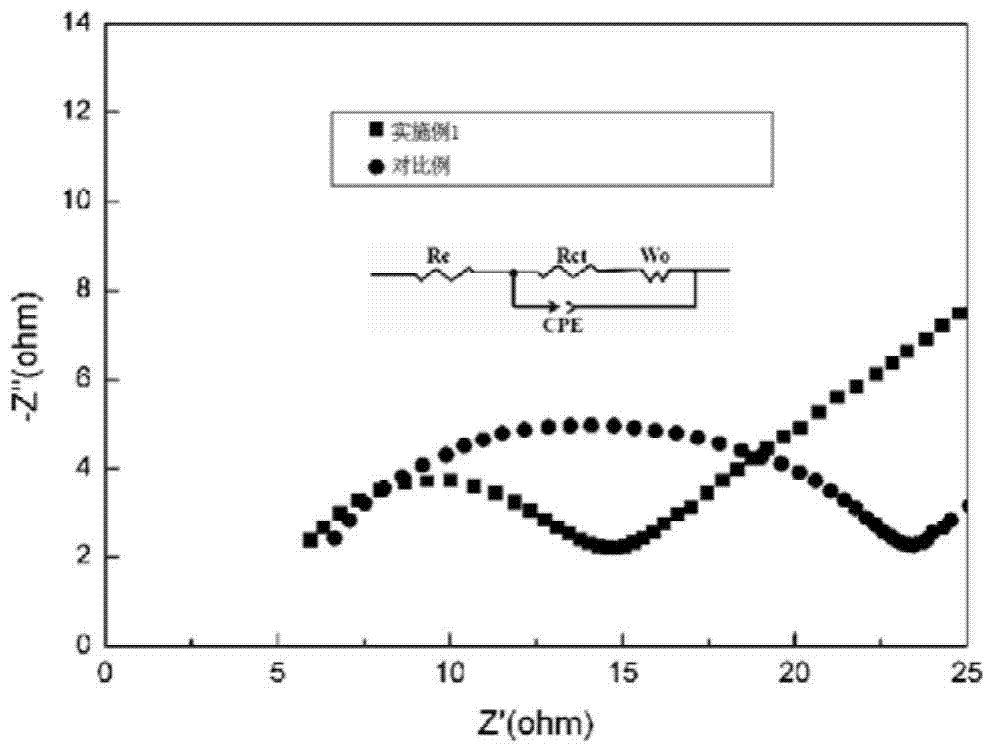

Embodiment 1

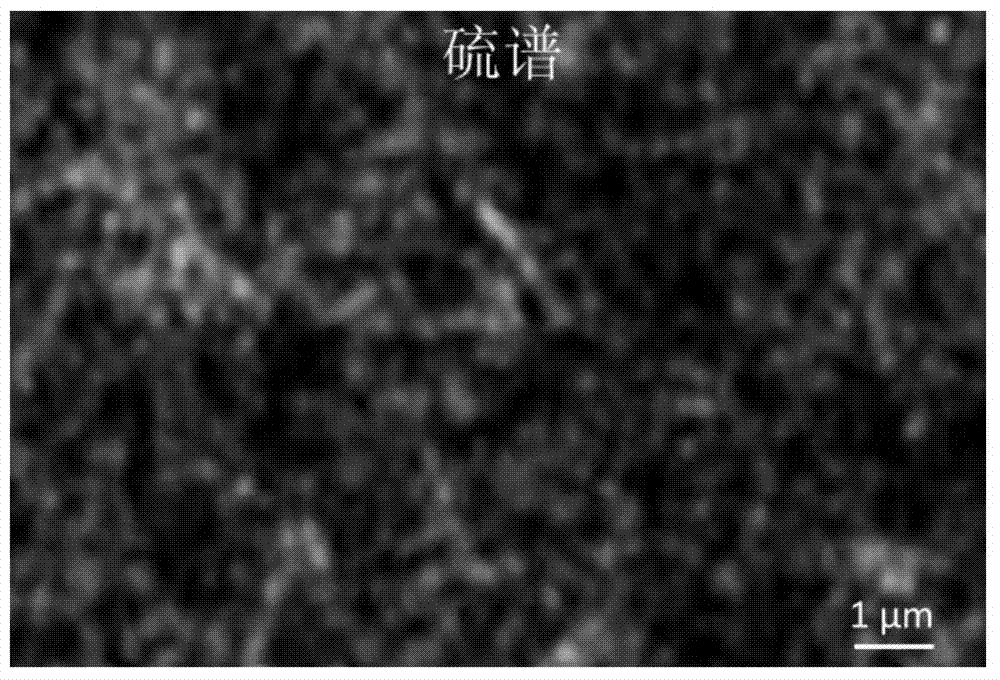

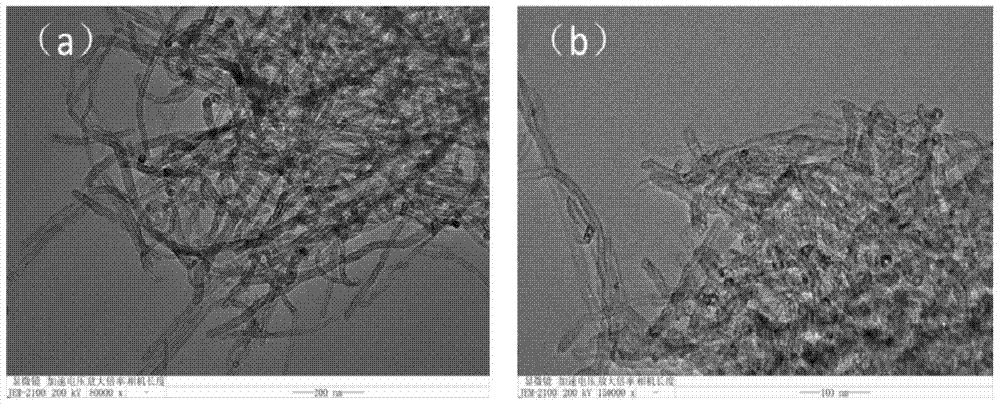

[0040] The positive electrode material of the lithium-sulfur battery in this embodiment includes a carbon-sulfur composite material, and the surface of the carbon-sulfur composite material is coated with a carbon coating layer, wherein the thickness of the carbon coating layer is 0.5 μm, and the pore volume of the carbon coating layer is 0.284 cm 3 / g, the particle size of the carbon-sulfur composite material is 2 μm.

[0041] The preparation method of the lithium-sulfur battery positive electrode material in this embodiment, the specific operation steps are:

[0042] 1) Put 1.8g of carbon nanotubes with a diameter of 20-40nm, 3.9g of sublimed sulfur, and 0.3g of glycine in an agate ball mill jar, control the speed of the planetary ball mill to 400r / min, and mill for 6 hours to obtain a uniform mixture;

[0043] 2) Transfer the homogeneous mixture prepared in step 1) to a vacuumable container, control the vacuum degree to 0.085MPa, raise the temperature from 25°C to 155°C, and...

Embodiment 2

[0050] The positive electrode material of the lithium-sulfur battery in this embodiment includes a carbon-sulfur composite material, and the surface of the carbon-sulfur composite material is coated with a carbon coating layer, wherein the thickness of the carbon coating layer is 4 μm, and the pore volume of the carbon coating layer is 0.241 cm 3 / g, the particle size of the carbon-sulfur composite material is 14 μm.

[0051] The preparation method of the lithium-sulfur battery positive electrode material in this embodiment, the specific operation steps are:

[0052] 1) 1.2g graphene, 4.2g sublimated sulfur, and 0.6g phenolic resin are placed in the ball mill jar of agate, the rotating speed of the planetary ball mill is controlled at 900r / min, and the ball mill is 12h to obtain a uniform mixture;

[0053] 2) Transfer the homogeneous mixture prepared in step 1) to a vacuumable container, control the vacuum degree to 0.095MPa, raise the temperature from 25°C to 155°C, and the h...

Embodiment 3

[0060] The positive electrode material of the lithium-sulfur battery in this embodiment includes a carbon-sulfur composite material, and the surface of the carbon-sulfur composite material is coated with a carbon coating layer, wherein the thickness of the carbon coating layer is 6 μm, and the pore volume of the carbon coating layer is 0.346 cm 3 / g, the particle size of the carbon-sulfur composite material is 27 μm.

[0061] The preparation method of the lithium-sulfur battery positive electrode material in this embodiment, the specific operation steps are:

[0062] 1) Put 2.1g meso-microporous carbon, 3.0g high-purity sulfur with a purity of 99.95%, and 0.90g precursor in an agate ball mill jar, where the precursor is a mixture of glucose and glycine at a mass ratio of 1:1 , control the rotating speed of planetary ball mill 600r / min, ball mill 20h, obtain homogeneous mixture;

[0063] 2) Transfer the homogeneous mixture prepared in step 1) to a vacuumable container, control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com