Composite diaphragm for lithium ion battery for lithium-sulfur battery and preparation method and application of composite diaphragm for lithium ion battery

A lithium-ion battery and composite diaphragm technology, applied in the field of electrochemical energy storage, can solve the problems of limited infiltration and adsorption capacity, large internal polarization of battery devices, and reduced safety performance, so as to improve electrochemical performance and safety performance, and improve thermal performance. Effects of stability and safety performance, excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

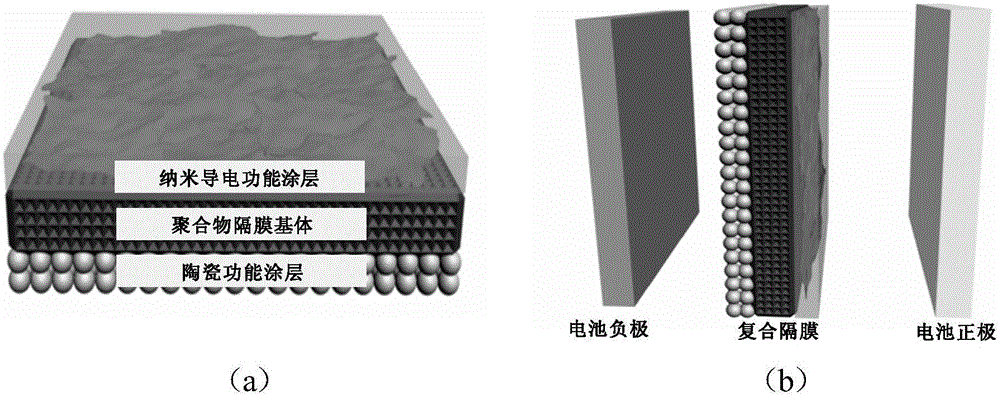

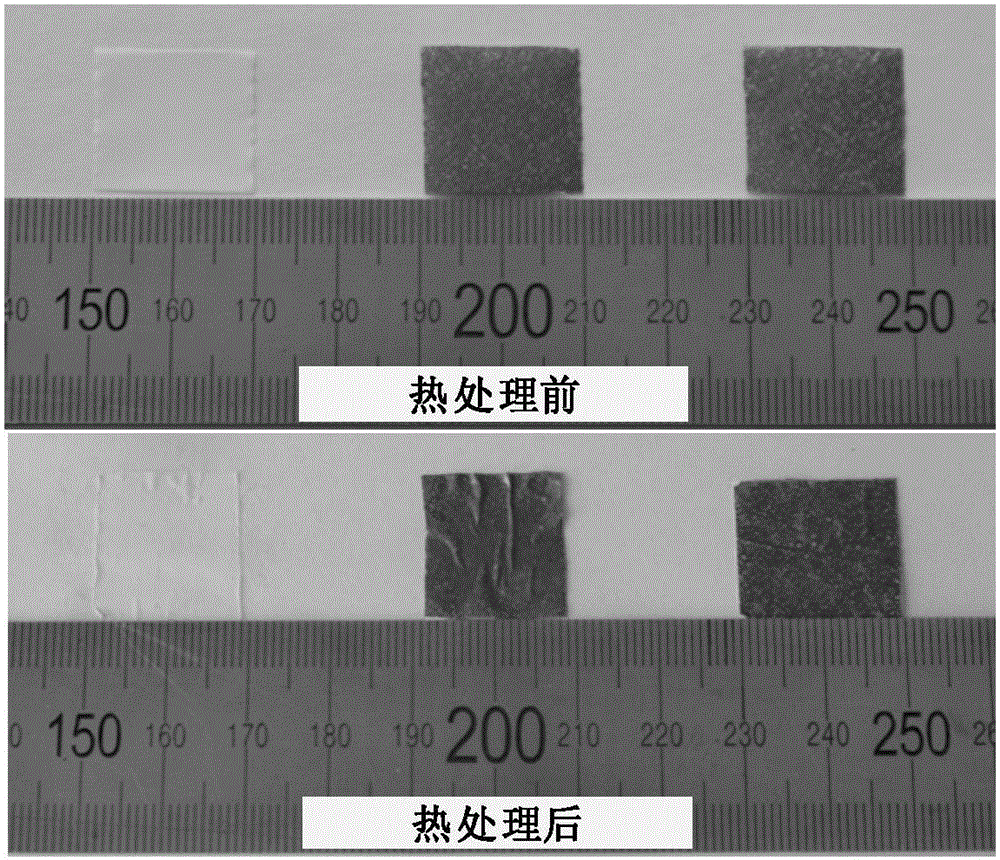

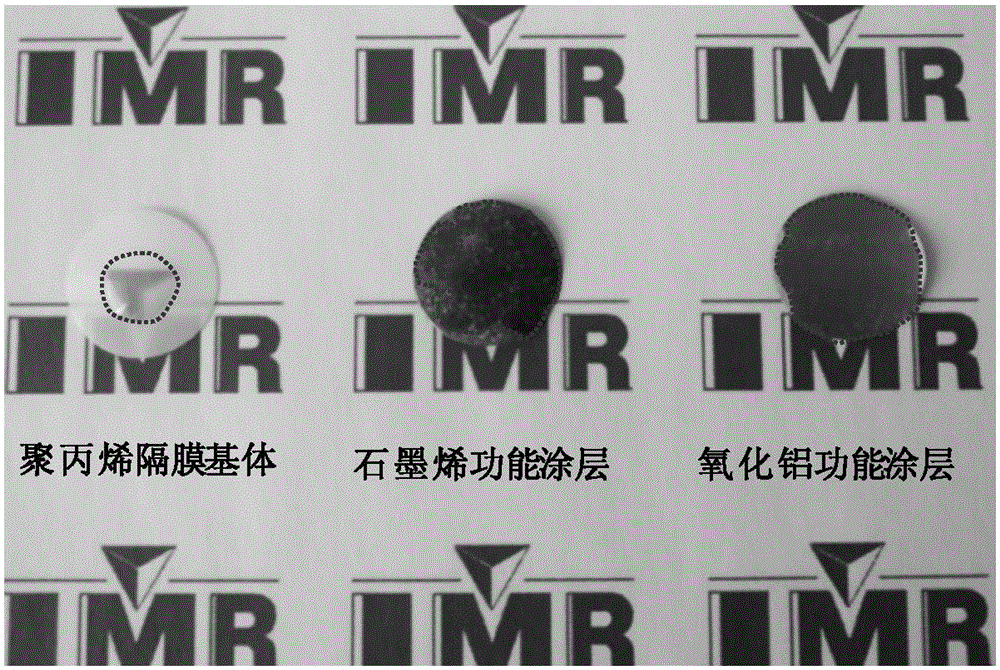

[0032] In this embodiment, the graphene nano-conductive functional coating and the alumina ceramic functional coating are respectively coated on both sides of the polypropylene diaphragm substrate to form a battery composite diaphragm, and it is assembled in a lithium-sulfur battery. The process is as follows:

[0033] 1. Preparation of single-functional graphene nano-conductive functional coating: first dissolve 1.016g of polyvinylidene fluoride (PVDF) in 253g of N-methylpyrrolidone (NMP) solvent, and stir with a mechanical stirrer at a rate of 700 rpm 1h to uniform, and configure a PVDF solution with a concentration of 0.4wt.%; add 4g of graphene powder obtained by the intercalation exfoliation method into the PVDF solution (the number of graphene layers is 3 to 7 layers, and the typical size of graphene is 5 to 7 layers). 10 μm), continue to use a mechanical stirrer to stir at a rate of 1000 rpm for 1 h to uniformly disperse the graphene in the PVDF solution, and prepare a g...

Embodiment 2

[0040] In this embodiment, carbon nanotube nano-conductive functional coating and alumina ceramic functional coating are respectively coated on both sides of the polypropylene diaphragm substrate to form a battery composite diaphragm, and it is assembled in a lithium-ion battery. The process is as follows:

[0041] 1. Preparation of single-functional carbon nanotube-coated diaphragm: First, 1.016g of polyvinylidene fluoride (PVDF) was dissolved in 253g of N-methylpyrrolidone (NMP) solvent, and a mechanical stirrer was used to stir at a rate of 700 rpm for 1h to Evenly, be configured into a PVDF solution of 0.4% content; 4g multi-walled carbon nanotube powder is added to the PVDF solution (its diameter is between 30-50 nanometers, and the length is 1-5 microns), and continue to use a mechanical stirrer to Stirring at a rate of revolutions per minute for 1 h until the carbon nanotubes are uniformly dispersed in the PVDF solution to prepare a carbon nanotube coating slurry. Subse...

Embodiment 3

[0046] In this embodiment, carbon black nano-conductive functional coating and alumina ceramic functional coating are respectively coated on both sides of the polypropylene diaphragm substrate to form a battery composite diaphragm, and it is assembled into a lithium-sulfur battery. The process is as follows:

[0047] 1. Preparation of single-functional nano-carbon black coating diaphragm: first, 1.016g of polyvinylidene fluoride (PVDF) was dissolved in 253g of N-methylpyrrolidone (NMP) solvent, and stirred at a rate of 700 rpm for 1h to Uniform, configured into a PVDF solution with a content of 0.4%; add 4g of nano-carbon black powder to the PVDF solution (its primary particle diameter is 40nm), continue to use a mechanical stirrer to stir at a rate of 1000 rpm for 1h until the nano-carbon black is uniform Disperse in PVDF solution to prepare nano carbon black coating slurry. Subsequently, the nano-carbon black slurry was uniformly coated on one side of a polypropylene diaphra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com