Lithium-sulfur battery membrane and lithium-sulfur battery with same

A lithium-sulfur battery and diaphragm technology, applied in the field of lithium-sulfur batteries, can solve the problems of unsatisfactory lithium-sulfur batteries, polysulfide conversion and low utilization rate, and achieve the effects of superior conductivity, suppressing the shuttle effect, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

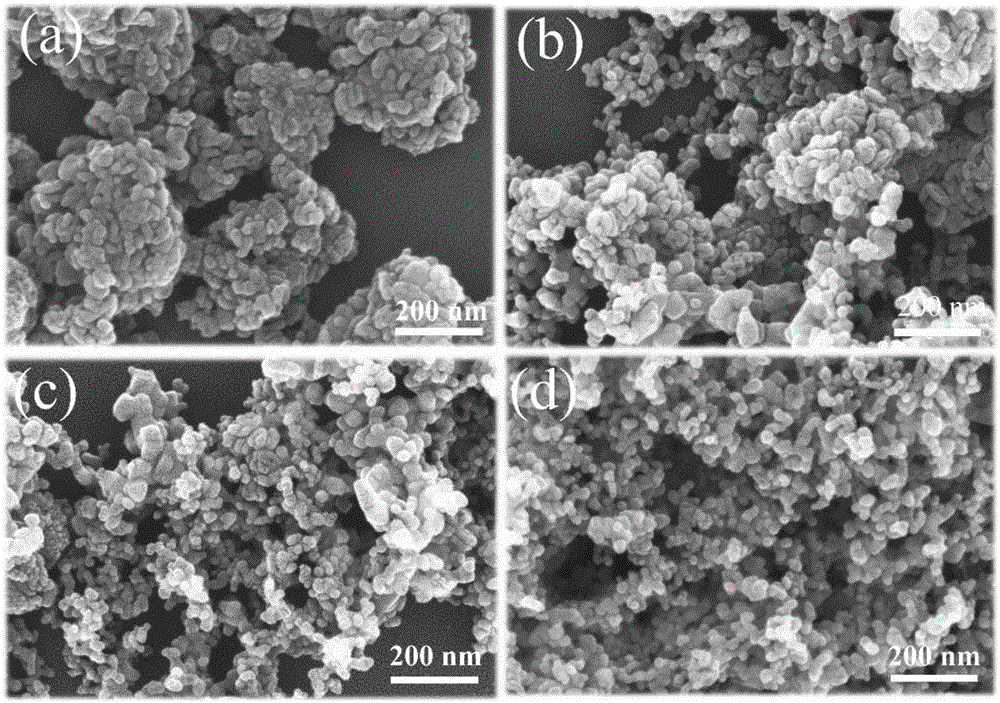

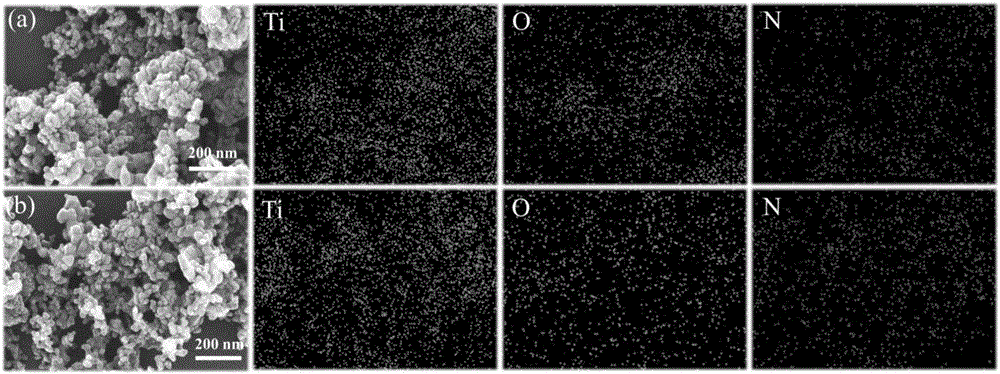

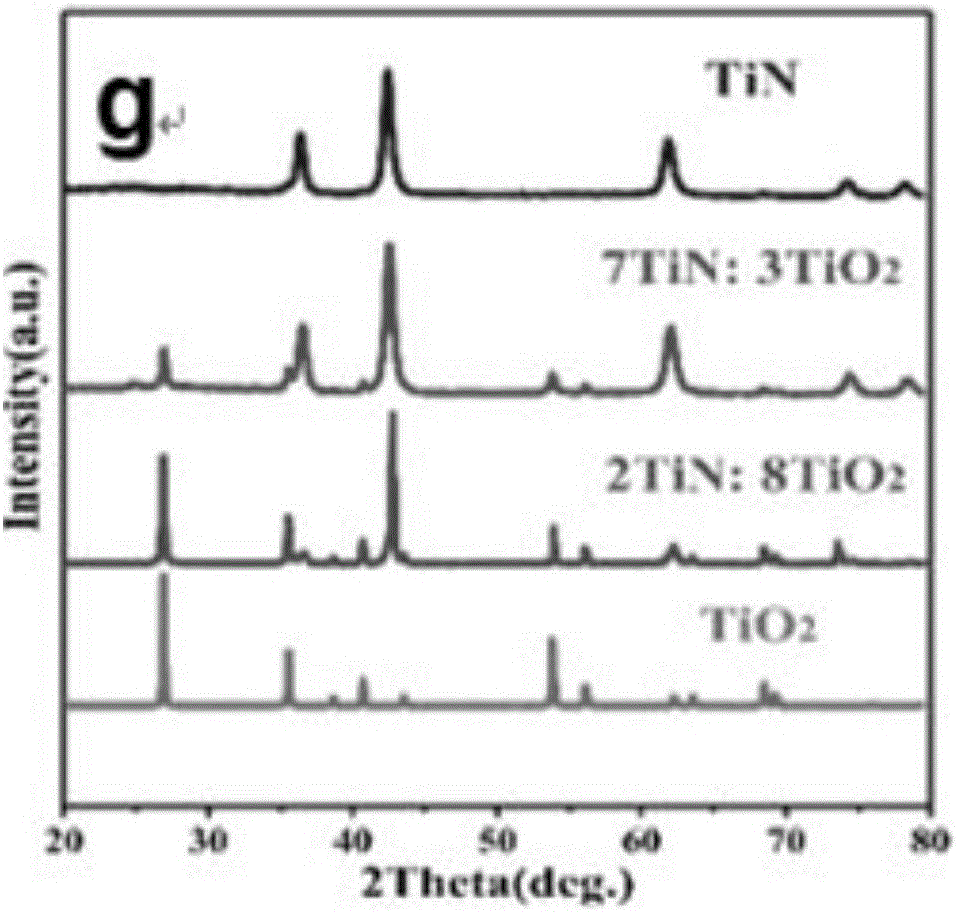

[0031] This embodiment provides a separator for a lithium-sulfur battery, which includes a separator base polyethylene porous membrane, and also includes a cover layer, the cover layer includes graphene and a heterojunction nanomaterial, and the heterojunction nanomaterial is a symbiotic rutile-type titanium dioxide- The mass ratio of titanium nitride, graphene and heterojunction nanomaterials is 9:1, and in the heterojunction nanomaterials, the mass ratio of rutile titanium dioxide to titanium nitride is 3:7.

[0032] Rutile titanium dioxide and titanium nitride are doped intergrowth structures, and there is a common interface between them.

[0033] The preparation method of heterojunction nanomaterials at least includes the following steps:

[0034] In the first step, urea is used as the nitrogen source, titanium tetrachloride is used as the titanium source, and the molar ratio of titanium tetrachloride and urea is controlled to be 1:8;

[0035] In the second step, disperse...

Embodiment 2

[0038]This embodiment provides a separator for a lithium-sulfur battery, which includes a separator base polypropylene porous membrane, and also includes a covering layer, the covering layer includes graphene and a heterojunction nanomaterial, and the heterojunction nanomaterial is a symbiotic rutile-type titanium dioxide- The mass ratio of titanium nitride, graphene and heterojunction nanomaterials is 9:1, and in the heterojunction nanomaterials, the mass ratio of rutile titanium dioxide to titanium nitride is 8:2.

[0039] Rutile titanium dioxide and titanium nitride are doped intergrowth structures, and there is a common interface between them.

[0040] The preparation method of heterojunction nanomaterials at least includes the following steps:

[0041] In the first step, urea is used as the nitrogen source, titanium tetrachloride is used as the titanium source, and the molar ratio of titanium tetrachloride and urea is controlled to be 1:8;

[0042] The second step is to ...

Embodiment 3

[0045] This embodiment provides a diaphragm for lithium-sulfur batteries, including a diaphragm substrate polyethylene / polypropylene composite diaphragm, and a covering layer, the covering layer includes graphene and heterojunction nanomaterials, and the heterojunction nanomaterials are symbiotic rutile Type titanium dioxide-titanium nitride, the mass ratio of graphene to heterojunction nanomaterials is 12:1, and in the heterojunction nanomaterials, the mass ratio of rutile titanium dioxide to titanium nitride is 5:5.

[0046] Rutile titanium dioxide and titanium nitride are doped intergrowth structures, and there is a common interface between them.

[0047] The preparation method of heterojunction nanomaterials at least includes the following steps:

[0048] In the first step, urea is used as the nitrogen source, titanium tetrachloride is used as the titanium source, and the molar ratio of titanium tetrachloride and urea is controlled to be 1:9;

[0049] The second step is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com