Preparation method of nitrogen-doped, boron-doped or phosphorus-doped graphitized carbon nitride material

A graphitization and carbon nitride technology, applied in active material electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., to achieve the effect of simple and easy preparation method, good electrical conductivity, and reduction of internal charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific implementation mode 1: This implementation mode records a method for preparing a nitrogen-doped graphitized carbon nitride material, and the method is specifically:

[0029] Take 5g ~ 10g of dicyandiamide and grind it fully in a mortar, then transfer it to a corundum crucible, cover the crucible with a lid to leave a hole of 1 / 8-1 / 7 lid length, put it into a muffle furnace at 300 ~ 400 Calcining at ℃ for 2h, then raising the temperature to 450-550℃ for 2h, the heating rate is 5℃min -1 , that is, a yellow powder is obtained, which is a nitrogen-doped graphitized carbon nitride material (g-C 3 N 4 ). g-C 3 N 4 The material contains a relatively high content of pyridine nitrogen, which can form a strong chemical bond with lithium polysulfide.

specific Embodiment approach 2

[0030] Embodiment 2: A method for preparing a conductive composite film using the nitrogen-doped graphitized carbon nitride material prepared in Embodiment 1. The method specifically includes: weighing nitrogen according to a mass ratio of 4:2:4 Doped graphitized carbon nitride material (g-C 3 N 4), conductive carbon black (BP2000) and PTFE emulsion (60wt.%), mix the three evenly (first put the nitrogen-doped graphitized carbon nitride material into a mortar and grind it fully, and then add conductive carbon black ( BP2000) to grind evenly, and finally add PTFE emulsion), and add 2~5mL deionized water to mix evenly, fully grind for 20min, remove water, roll press, die cut, dry, and control the thickness to 30~60mm. Specifically, put it into a blast oven to dry until there is no moisture on the surface, then transfer it to a small roller press for rolling into a film, and finally punch it into a pole piece with a diameter of 16mm, and dry it in vacuum at 60°C for 24h. Use a m...

specific Embodiment approach 3

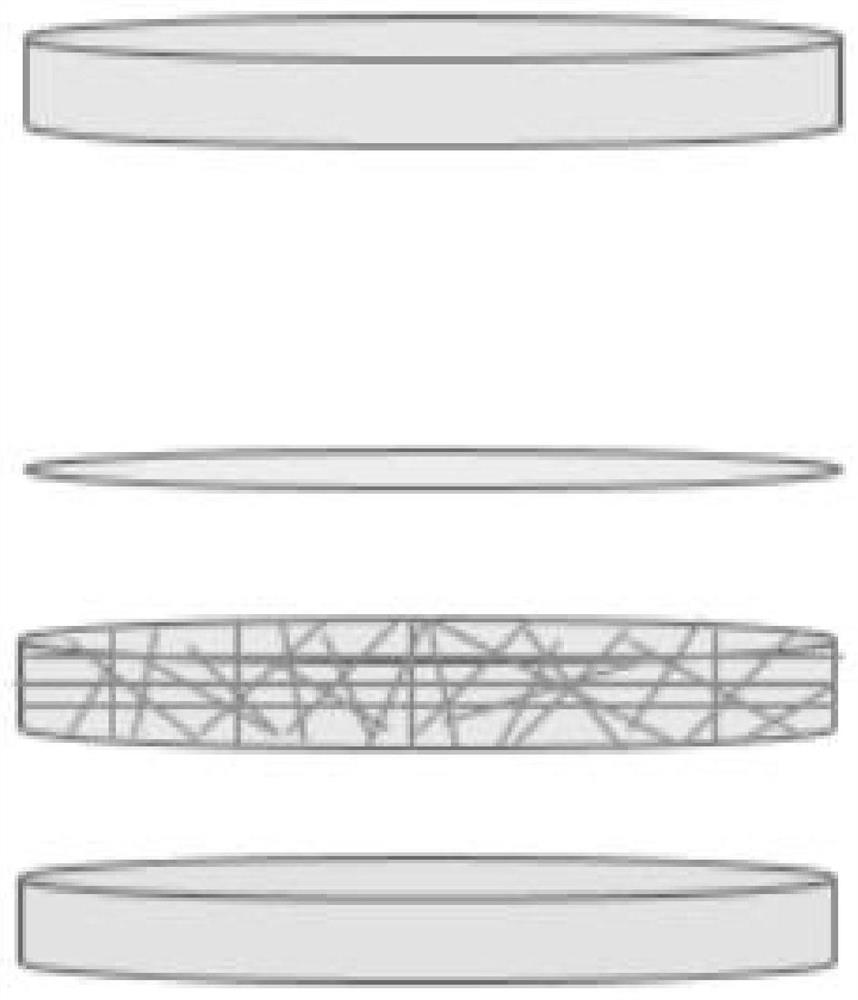

[0031] Specific embodiment three: the application of the conductive composite film prepared in specific embodiment two in lithium-sulfur batteries, the conductive composite film is embedded between the sulfur positive electrode and the separator, which can effectively block the soluble polysulfide from the lithium negative electrode diffusion and migration. in figure 1 From top to bottom, respectively represent the lithium anode, the separator, the g-C 3 N 4 The composite membrane intercalation and the battery structure of the composite sulfur cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com