Method for preparing positive electrode composite material

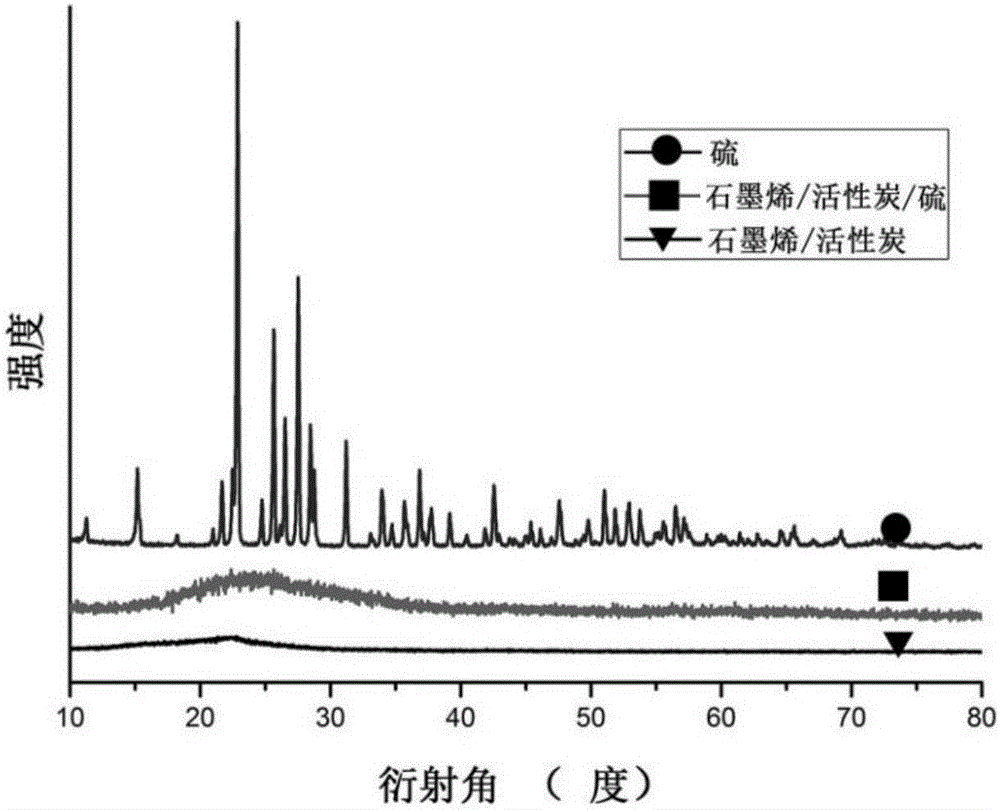

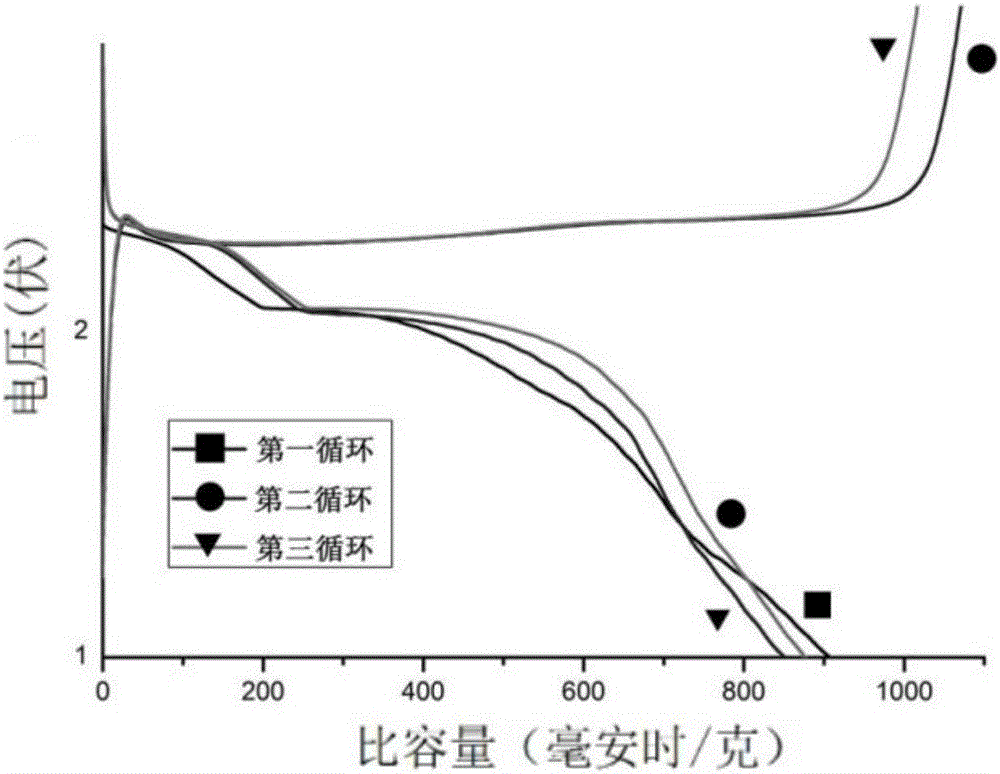

A composite material and cathode technology, which is applied in the field of graphene/activated carbon/sulfur composite cathode material preparation, can solve the problems of disrupting the ecological balance of the earth, resource shortage mining costs, battery capacity attenuation, etc., and achieves improved utilization and stable discharge. The effect of good cycle performance and increased discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Utilize the Hummers method to prepare graphene oxide; (Hummers method is an existing public method, which will not be described in detail here), take 20mg graphene oxide and add 10mL deionized water, ultrasonic 1h, get 2mg / mL graphene oxide suspension;

[0029] (2) 3 mg of acid-treated activated carbon (acid treatment process is: 1, the activated carbon of 5 g is added to 50 mL of concentrated nitric acid with a concentration of 68% by mass, and the mixed suspension is placed in a magnetic stirrer and stirred for 1 h ; 2. Centrifuge the suspension obtained in 1 to obtain acid-treated activated carbon; 3. Wash the treated activated carbon with water until the pH value is 7, and finally place it in a drying oven at 60 ° C for 10 h) and add it to 1.5 mL of graphite oxide olefin suspension (2mg / mL), sonicate at room temperature for 10min, then stand at room temperature for 10min;

[0030] (3) Take 1mL of the mixed solution obtained in (2), then add 20mg of 1mol / L sodiu...

Embodiment 2

[0037] (1) Utilize Hummers method to prepare graphene oxide, take 40mg graphene oxide and add 10mL deionized water, ultrasonic 3h, obtain 4mg / mL graphene oxide suspension;

[0038] (2) 3 mg of acid-treated activated carbon was added to 1.5 mL of graphene oxide suspension (4 mg / mL), ultrasonicated at room temperature for 10 min, and then left to stand at room temperature for 10 min;

[0039] (3) Take 1mL of the mixed solution obtained in (2), then add 60mg of 1mol / L sodium ascorbate solution, then place it in an oil bath, and heat it at 100°C for 120min to obtain a graphene hydrogel;

[0040] (4) the graphene hydrogel obtained in (3) is placed in a drying oven and dried at 90° C. for 6 hours to obtain a graphene / activated carbon composite material;

[0041] (5) Fully grind the graphene / activated carbon composite material obtained in (4) with a mass ratio of 1:1 for 3 hours, use a ball mill for grinding, and then put it in a tube furnace for calcination at 170°C for 5 hours unde...

Embodiment 3

[0045] (1) Graphene oxide was prepared by the Hummers method; 20 mg of graphene oxide was added to 10 mL of deionized water, and ultrasonicated for 1 hour to obtain a 2 mg / mL graphene oxide suspension;

[0046] (2) 3 mg of acid-treated activated carbon was added to 1.5 mL of graphene oxide suspension (2 mg / mL), ultrasonicated at room temperature for 10 min, and then left to stand at room temperature for 10 min;

[0047] (3) Take 1mL of the mixed solution obtained in (2), then add 20mg of 2mol / L sodium ascorbate solution, then place it in an oil bath, and heat it at 100°C for 120min to obtain a graphene hydrogel;

[0048] (4) the graphene hydrogel obtained in (3) is placed in a drying box and dried at 60° C. for 12 hours to obtain a graphene / activated carbon composite material;

[0049] (5) Graphene / activated carbon and sulfur mass ratio obtained in (4) are fully ground 3h at 1:1, and the ball mill is selected for grinding, and then placed in a tube furnace and calcined at 155°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com