Silicon-carbon negative electrode material, preparation method and lithium ion battery

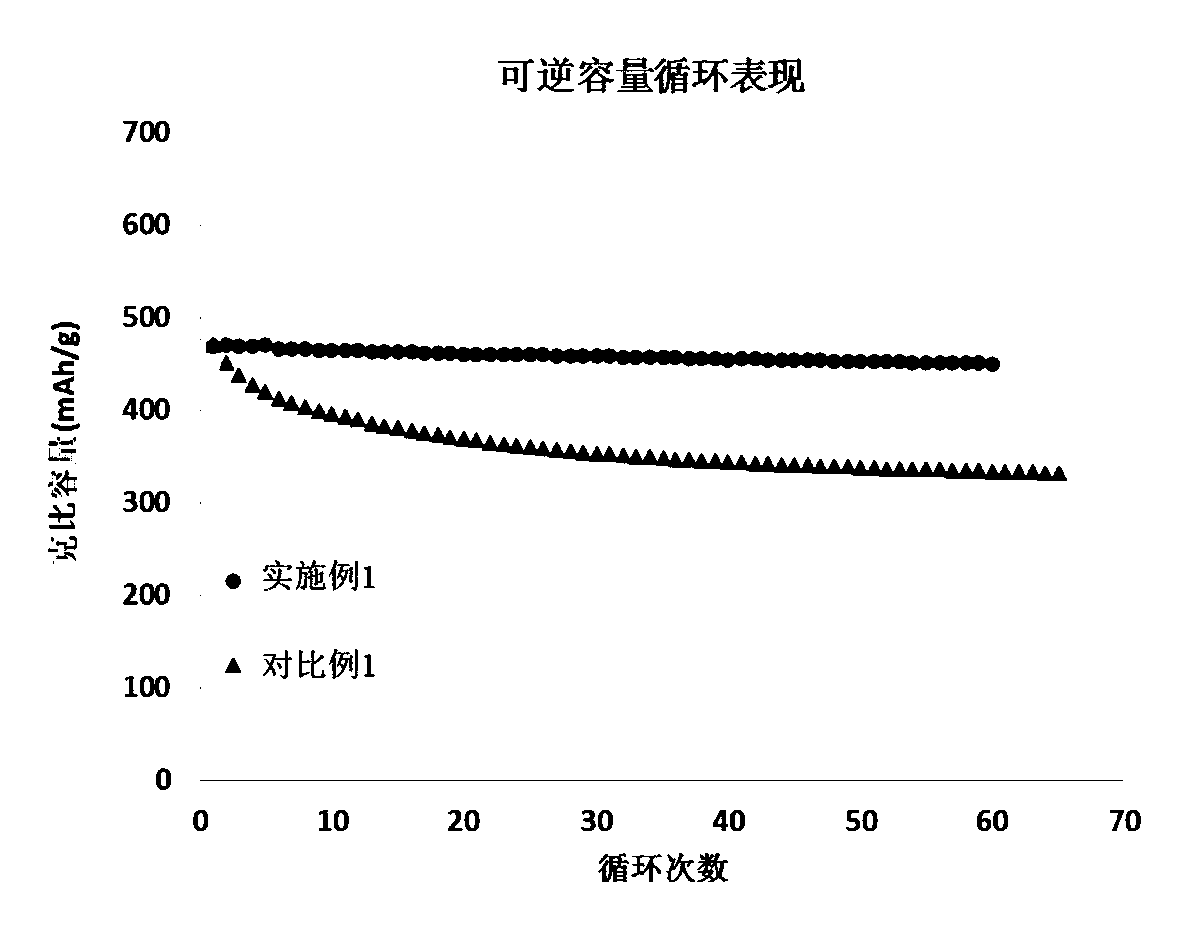

A negative electrode material, silicon carbon technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor volume expansion cycle performance, difficulty in particle dispersion, and increased stress of lithium intercalation expansion, etc., to achieve good kinetic performance, Effect of improving cycle performance and reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

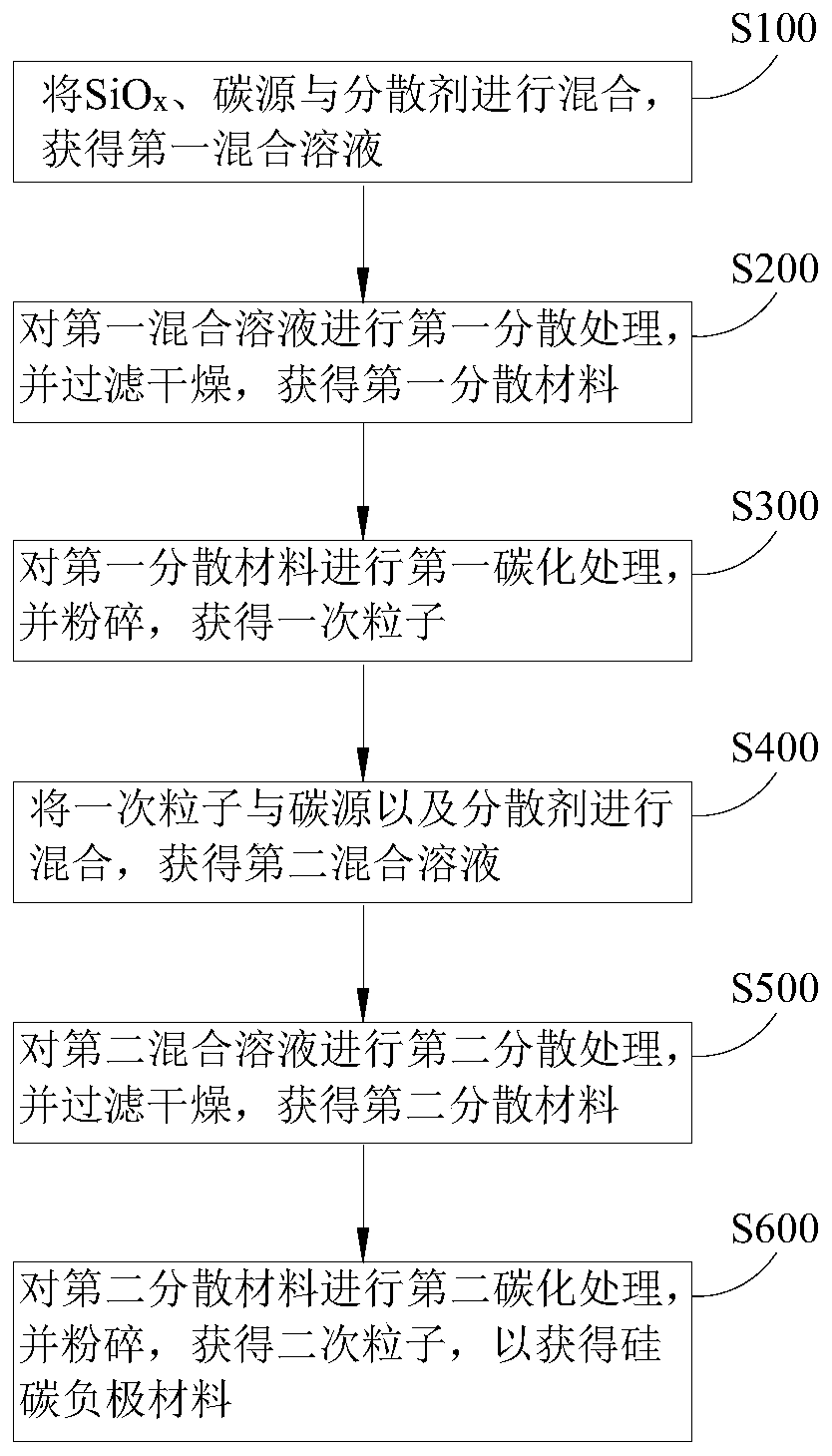

Method used

Image

Examples

Embodiment 1

[0052] (1) Prepare the first mixed solution. Select SiO with a particle size of 100 nm, mix SiO and asphalt at a mass ratio of 1:10, and then add ethanol to obtain the first mixed solution. The ratio of the mass of ethanol to the total mass of SiO and asphalt is 1.5:1.

[0053] (2) Prepare the first dispersion material. The first dispersing treatment was performed on the first mixed solution by using a dispersing machine, the rotation speed of the first dispersing treatment was 600 rpm, and the time was 3 hours. After dispersing, the first dispersing material was obtained by filtering and drying.

[0054] (3) Preparation of primary particles. Put the first dispersion material into a tube furnace, pass high-purity nitrogen gas as a protective gas, start from room temperature at a rate of 5°C / min to 700°C, and keep the temperature constant for 15h to obtain a carbon-coated SiO material. Subsequently, the above material was pulverized to obtain primary particles having a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com