Hollow-structure carbon and silicon negative pole material used for lithium ion battery, and preparation method of hollow-structure carbon and silicon negative pole material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as difficult to ensure rapid transmission of lithium ions and electrons, and achieve improved volume expansion, good cycle stability, and The effect of low swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

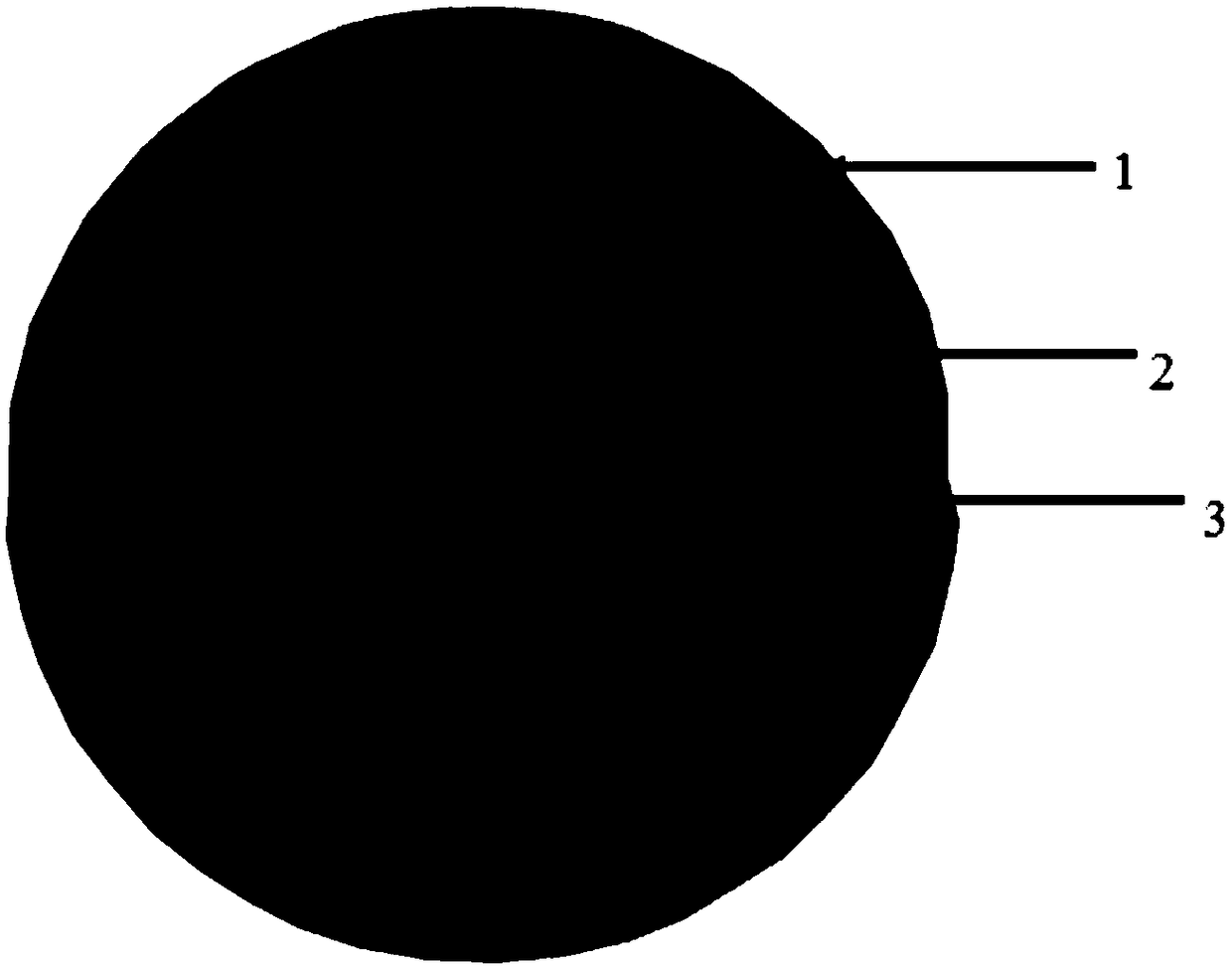

[0034] Such as figure 1 As shown, the present embodiment provides a silicon-carbon negative electrode material with a hollow structure for lithium-ion batteries. The interior of the negative electrode material is a hollow structure, and the wall layer of the negative electrode material includes an inner wall and an outer wall, and the inner wall is made of nano-silicon 2 and the low-carbon residual carbon source 3 are homogeneously composited, and the outer wall is a carbon coating layer 1 formed by organic cracking carbon source;

[0035] The particle size of the nano-silicon 2 is 30nm;

[0036] The softening point of the low carbon residue carbon source 3 is <200°C, and the carbon residue rate is <40%;

[0037] The thickness of the outer wall is 0.1-10 μm;

[0038] The thickness of the inner wall is 1-8 μm.

[0039] In the negative electrode material, the mass percentage of nano-silicon is 41.2%, the mass percentage of the low-carbon residual carbon source is 18.7%, and t...

Embodiment 2

[0047] This embodiment provides a silicon-carbon negative electrode material with a hollow structure for lithium-ion batteries. The interior of the negative electrode material is a hollow structure, and the wall layer of the negative electrode material includes an inner wall and an outer wall, and the inner wall is made of nano-silicon and low residue. Carbon and carbon sources are formed by homogeneous compounding, and the outer wall is a carbon coating layer formed by organic cracking of carbon sources;

[0048] The particle size of the nano-silicon is 60nm;

[0049] The softening point of the low carbon residue carbon source is <200°C, and the carbon residue rate is <40%;

[0050] The thickness of the outer wall is 0.1-10 μm;

[0051] The thickness of the inner wall is 1-8 μm.

[0052] In the negative electrode material, the mass percentage of nano-silicon is 37.3%, the mass percentage of the low carbon residue carbon source is 34.9%, and the mass percentage of the carbon...

Embodiment 3

[0060] This embodiment provides a silicon-carbon negative electrode material with a hollow structure for lithium-ion batteries. The interior of the negative electrode material is a hollow structure, and the wall layer of the negative electrode material includes an inner wall and an outer wall, and the inner wall is made of nano-silicon and low residue. Carbon and carbon sources are formed by homogeneous compounding, and the outer wall is a carbon coating layer formed by organic cracking of carbon sources;

[0061] The particle size of the nano-silicon is 30nm;

[0062] The softening point of the low carbon residue carbon source is <200°C, and the carbon residue rate is <40%;

[0063] The thickness of the outer wall is 0.1-10 μm;

[0064] The thickness of the inner wall is 1-8 μm.

[0065] In the negative electrode material, the mass percentage of nano-silicon is 22.1%, the mass percentage of the low carbon residue carbon source is 44.5%, and the mass percentage of the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com