Low-expansion silicon-based composite material and manufacturing method thereof, silicon-based anode material and lithium ion battery

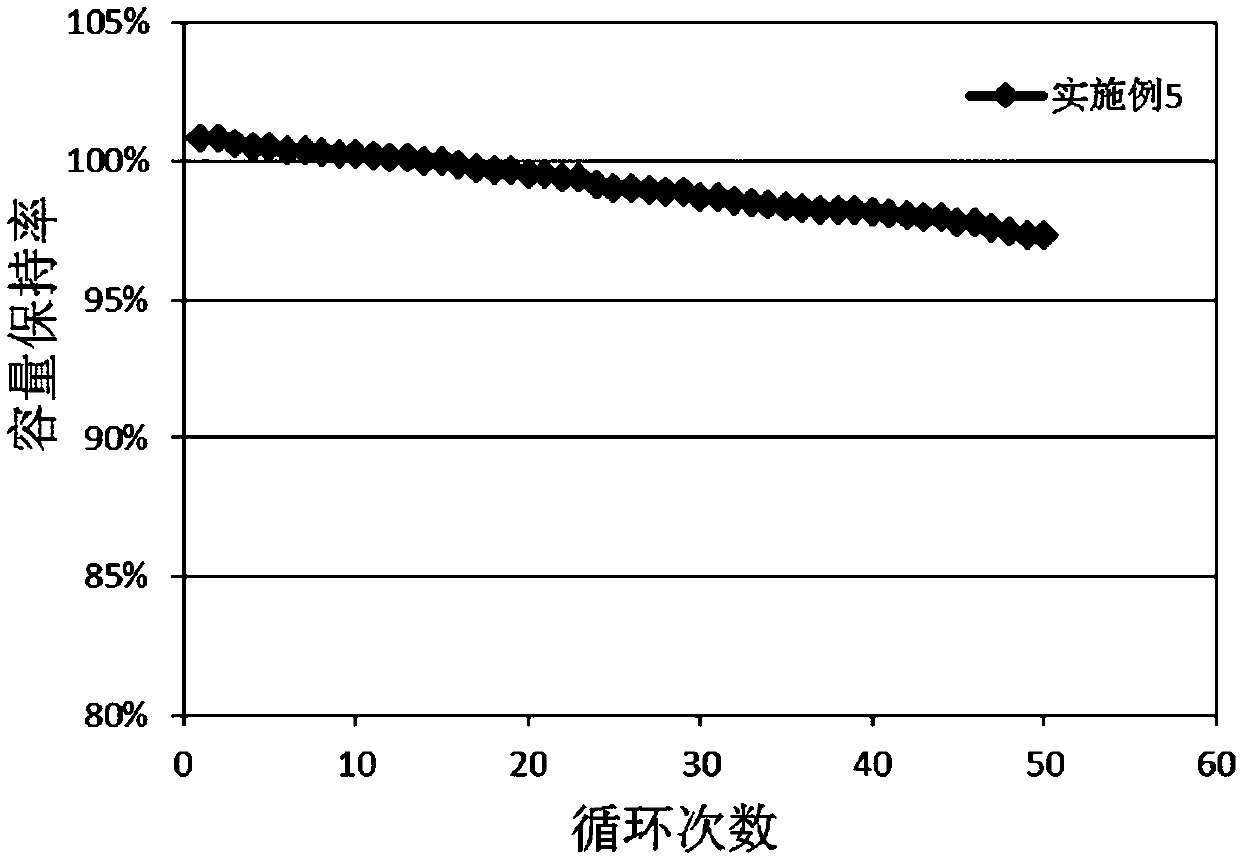

A technology of silicon-based composite materials and silicon-based negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large volume expansion and cannot effectively alleviate the negative electrode volume expansion, and achieve low full charge rebound and improve battery performance. Cycling performance, effect of reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 of the preparation method of the low-expansion silicon-based composite material of the present invention is specifically prepared by the following steps:

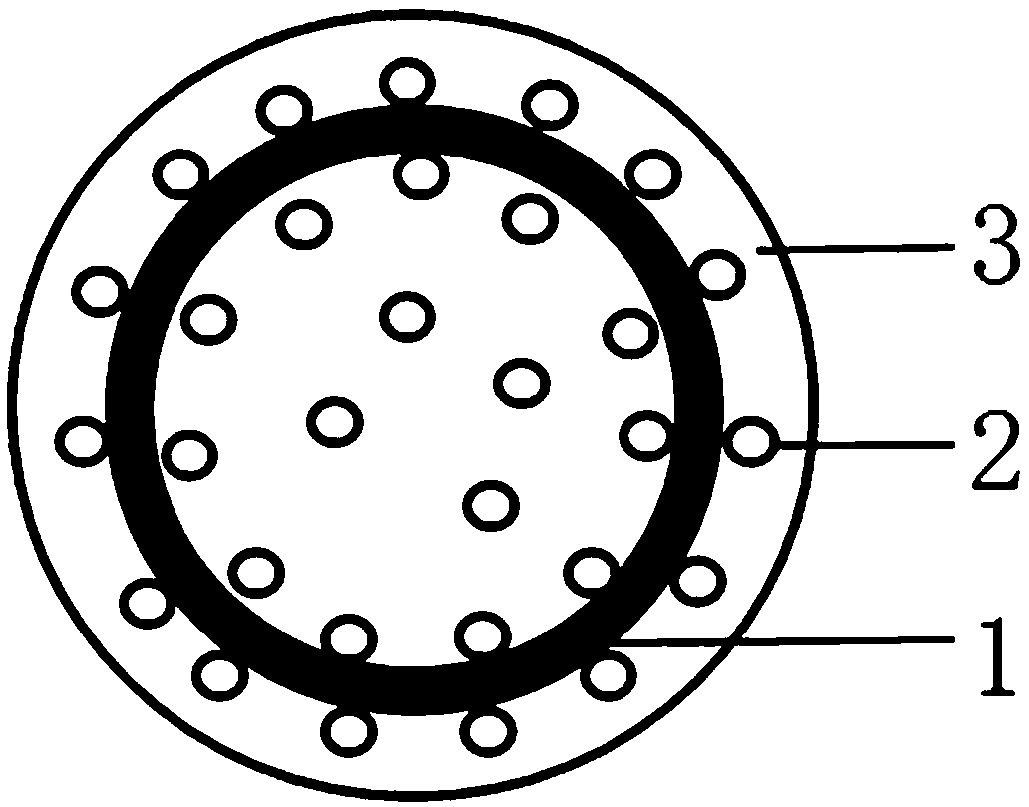

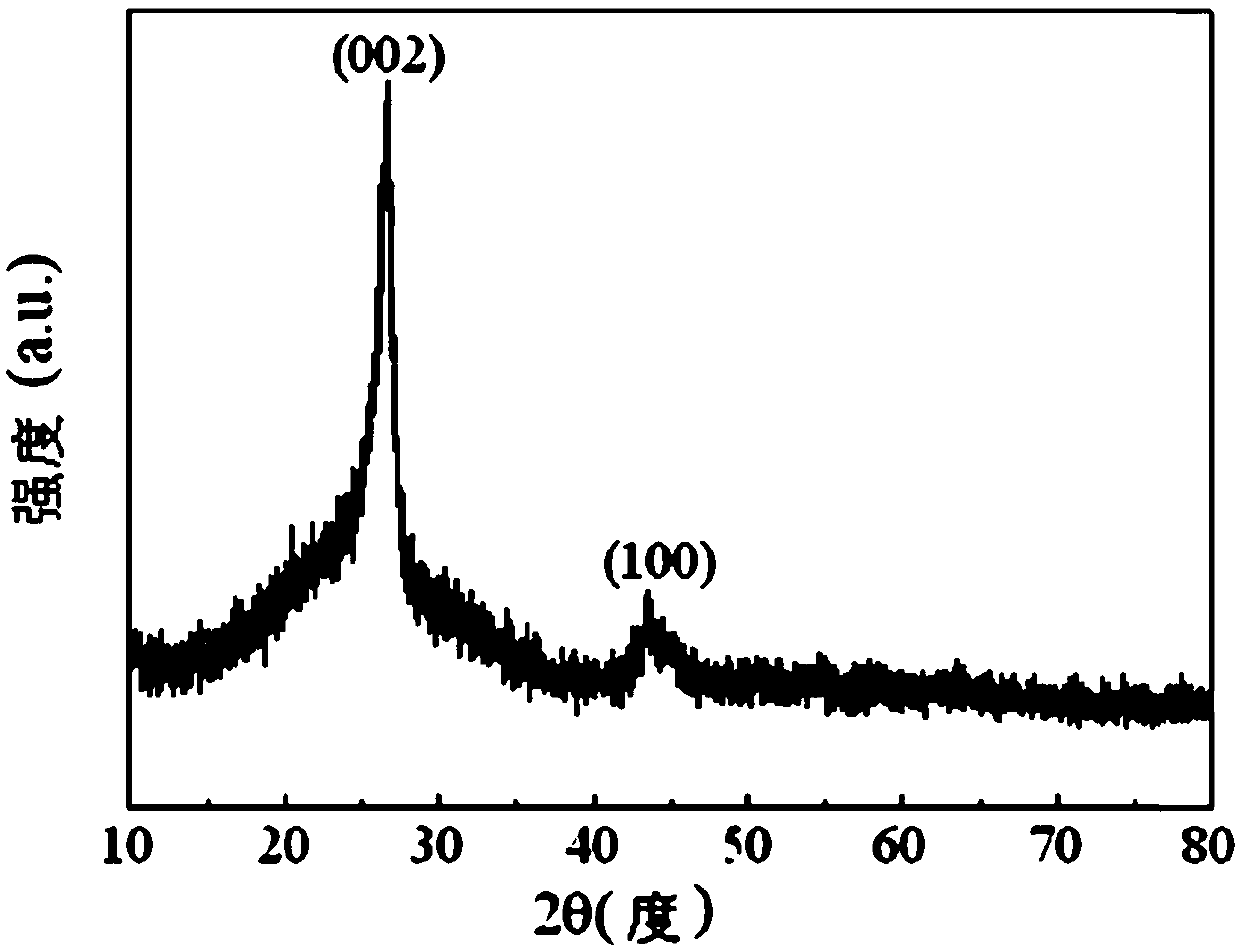

[0042] 1) Weigh 1000g of liquid polyacrylonitrile in a porcelain boat, place it in a muffle furnace and raise the temperature to 250°C at 5°C / min, keep it warm for 4h, cool it down to room temperature naturally, and grind the obtained solid matter with a mortar; weigh Put 200g of the ground solid substance in a porcelain boat, place it in a tube furnace, pass in argon gas, set the furnace pressure at 0.8MPa, set the temperature at 1000°C, and heat it at a rate of 5°C / min for 10h; Cool down to 200°C at a rate of ℃ / min, and then cool naturally to room temperature to obtain a sintered solid (that is, carbon microtubes to be processed). The diameter of the carbon microtubes to be processed is 0.1-2 μm, the wall thickness is 5-30 nm, and the specific surface area 100-1000g / m 2 .

[0043] Disperse the sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com