Ethane recycling method applied to rich gas and with self-cooling circulation

A recovery method and ethane technology, which is applied in the field of gas-rich ethane recovery, can solve the problems of high power consumption of external compressors, reduced gas phase volume of turbine expansion, and large refrigerant circulation volume, etc., to achieve improved ethane recovery rate, lower separation load, and reduced effect of storage and distribution devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

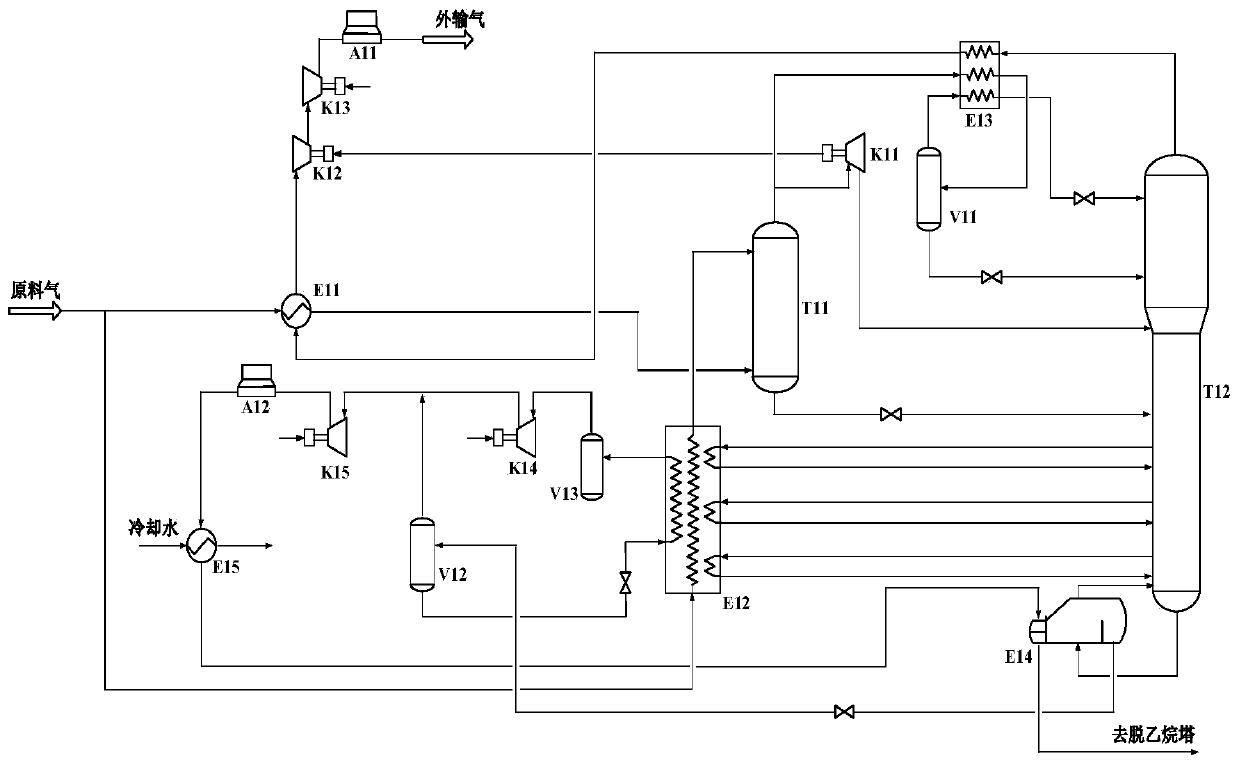

[0036] Such as figure 1 As shown, the composition and working conditions of 4 feed gas are as follows:

[0037] Raw material gas treatment scale: 500×104m 3 / d

[0038] Raw gas pressure: 5.0MPa

[0039] Raw gas temperature: 15°C

[0040] Dry gas output pressure: 5.0MPa

[0041] The raw gas composition is shown in Table 1

[0042] Table 1 Feed gas composition

[0043] composition N 2

CO 2

C 1

C 2

C 3

iC 4

c 4

iC 5

c 5

C 6

mol% 1.24 0.04 73.77 14.29 7.55 0.73 1.84 0.23 0.21 0.1

[0044] Such as figure 1 As shown, the present invention discloses an ethane recovery process suitable for rich gas with a refrigeration cycle,

[0045] The raw material gas (5000kPa, 15°C) is divided into two streams at the inlet, 22mol% of which is exchanged with the external gas to -35°C and then enters the lower part of the absorption tower (T11), and 78mol% is desorbed in the multi-strand cold box (E12). The 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com