Purification method and purification system of electronic-grade tetraethoxysilane

A technology of ethyl orthosilicate and purification method, which is applied in the field of purification method and purification system of electronic grade ethyl orthosilicate, can solve the problems of incapable of continuous production, high production cost, large energy consumption and the like, and achieves easy operation, Low cost and effect of reducing separation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

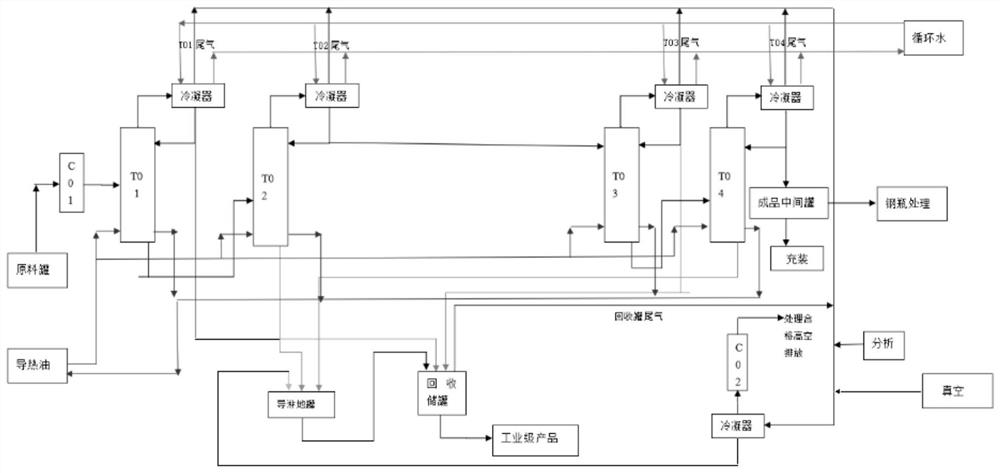

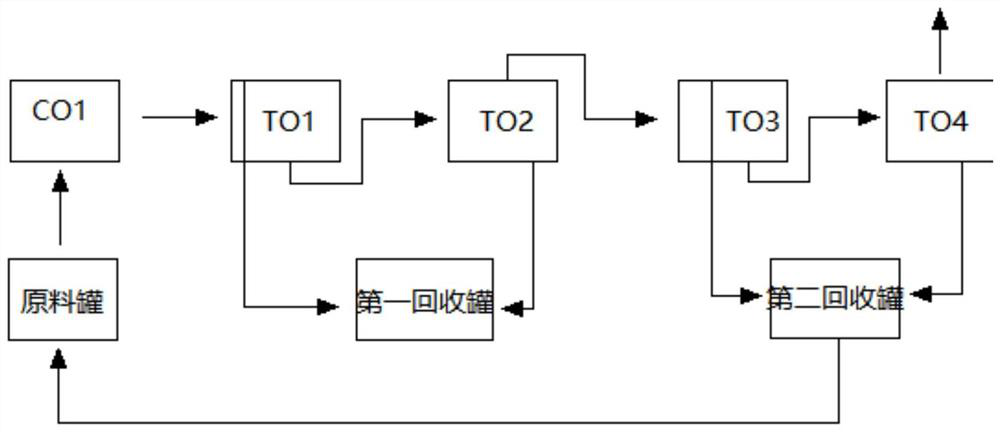

[0040] Please refer to figure 1 , a purification system for electronic-grade orthosilicate, comprising a raw material tank for storing and outputting orthosilicate; an adsorption column communicated with the discharge end of the raw material tank; a first rectification tower connected with The discharge end of the adsorption column is communicated; the second rectification tower is communicated with the bottom of the first rectification tower; the third rectification tower is communicated with the top of the second rectification tower; the fourth rectification tower is communicated with the top of the second rectification tower; A rectification tower communicates with the bottom of the second rectification tower.

[0041] Also comprising the first recovery tank, its feed end is connected with the tower top of the first rectification tower and the bottom of the second rectification tower; the second recovery tank, its feed end is connected with the third rectification tower Th...

Embodiment 2

[0043] This embodiment is carried out on the basis of the above-mentioned embodiment 1, and the similarities with the above-mentioned embodiment will not be repeated.

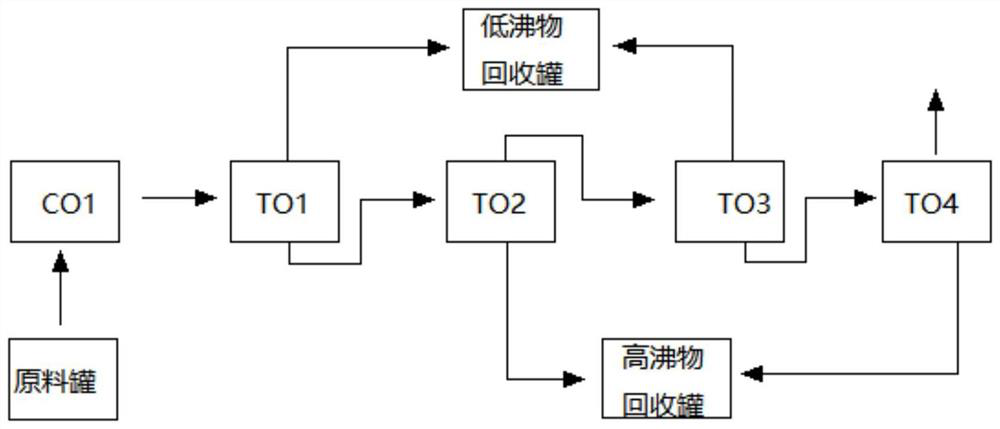

[0044] Please refer to figure 2 , the first recovery tank and the second recovery tank are replaced by a low boiler recovery tank and a high boiler recovery tank; The top of the distillation tower is connected; the feed end of the high boiler recovery tank is connected with the bottom of the second rectification column and the bottom of the fourth rectification column; the low boiler recovery tank and the high boiler recovery tank are respectively A deluge system is connected; part of tetraethyl orthosilicate, water vapor, ethanol, ether and others are recovered in the low boiling matter recovery tank; part of tetraethyl orthosilicate, high Silicon tetrachloride, monomethoxytriethoxy silicon, metal ions and others.

Embodiment 3

[0046] This embodiment mainly introduces a method for purifying electronic grade orthosilicate, the steps are as follows:

[0047] S100) filling with nitrogen;

[0048] Wherein, the nitrogen filling in step S100) specifically includes opening the communication valve inside the system, closing the communication valve connecting the system to the outside, performing nitrogen filling and pressure relief operations in the system, and repeating the above operations at least three times;

[0049] More specifically, first check the heating medium temperature, pressure, circulating soft water pressure, flow rate, nitrogen pressure, instrument air pressure, exhaust gas environmental protection treatment device input and pipeline inspection, etc., to ensure that all pneumatic valves in the system have been debugged and act normally, and Consistent with the computer display; then open the internal communication valve of the system, close the communication valve connecting the system to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com