Method for separating and purifying DHA ethyl ester from DHA oil fermented by microorganisms

A microbial fermentation, separation and purification technology, which is applied in the field of separation and purification to prepare DHA ethyl ester, can solve the problems of high cost and unsatisfactory purification effect, and achieve the effects of ensuring quality, improving DHA purification degree, and high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

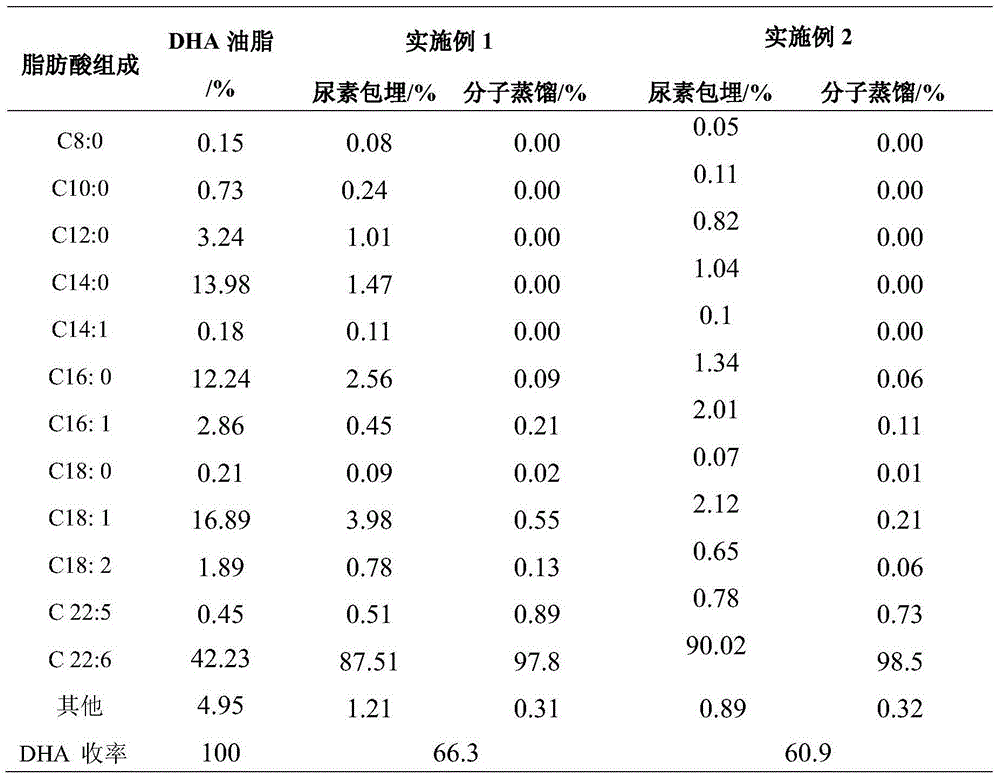

Embodiment 1

[0027](1) Ethyl esterification of DHA oil: Dissolve 4g KOH in 160g ethanol, mix 500g of DHA oil (DHA accounts for 42.23%) produced by the fermentation of Cryptodinium algae with KOH-ethanol solution, under the condition of nitrogen filling, Heated to reflux in a water bath at 60°C for 0.5h. Cool to room temperature under the condition of nitrogen filling, after static layering, take the upper layer of DHA ethyl ester, distill under reduced pressure at 60°C and -0.1Mpa to recover ethanol, then use 40°C warm water to wash repeatedly until the washing water is neutral, after oil-water separation , the oil phase passes through anhydrous Na 2 SO 4 Filter and dry to obtain 464.15 g of ethyl-esterified DHA oil.

[0028] (2) Urea embedding - primary separation of gradient freeze crystallization: Prepare a urea ethanol solution with a mass fraction of 20%, and heat and reflux in a water bath at 65°C until the urea is completely dissolved. After mixing the ethyl-esterified DHA oil an...

Embodiment 2

[0034] (1) Ethylification of DHA oil: Dissolve 7.5g KOH in 500g ethanol, and fully mix 500g of DHA oil (DHA accounts for 42.23%) produced by the fermentation of Cryptodinium algae with KOH-ethanol solution. Heated to reflux in a water bath at 50°C for 4h. Cool to room temperature under the condition of nitrogen filling, after static layering, take the upper layer of DHA ethyl ester, distill under reduced pressure at 60°C and -0.1Mpa to recover ethanol, then use 40°C warm water to wash repeatedly until the washing water is neutral, after oil-water separation , the oil phase was filtered and dried by anhydrous Na2SO4 to obtain 472.1 g of ethyl-esterified DHA grease.

[0035] (2) Urea embedding - primary separation of gradient freeze crystallization: prepare a urea ethanol solution with a mass fraction of 30%, and heat and reflux in a water bath at 70°C until the urea is completely dissolved. Ethyl-esterified DHA oil and 30% urea ethanol were mixed evenly at a mass ratio of 1:10...

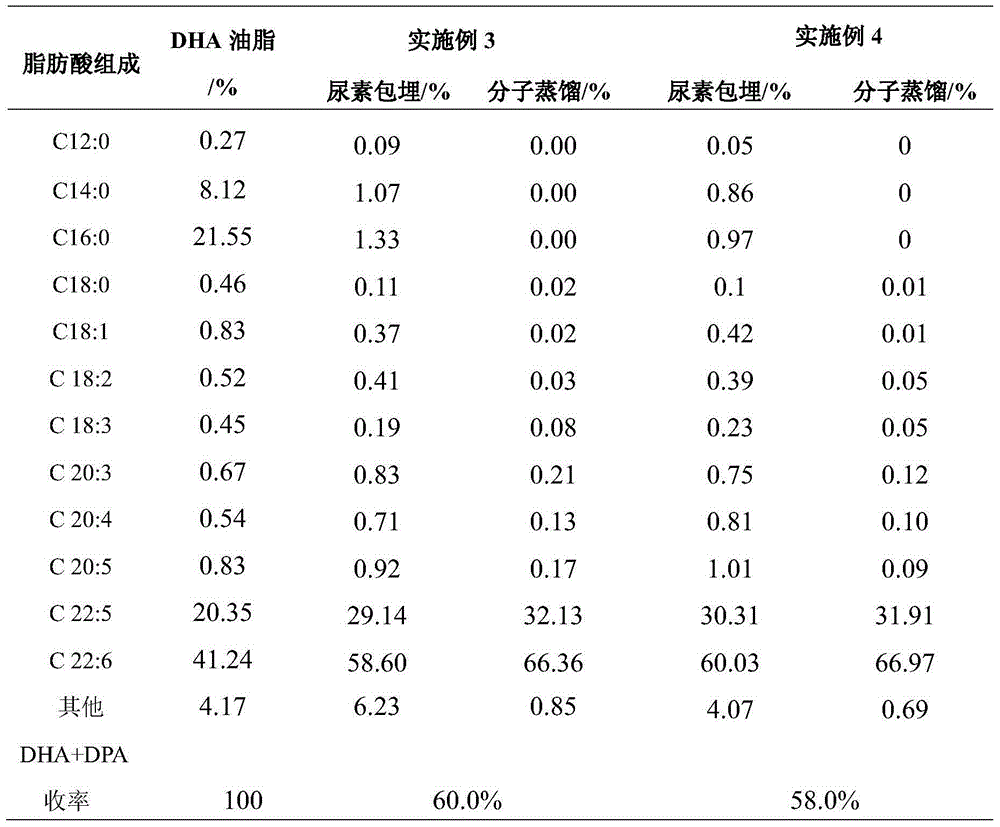

Embodiment 3

[0043] (1) Ethyl esterification of DHA oil: Dissolve 5g KOH in 150g ethanol, and fully mix 500g of mixed oil (DHA accounts for 41.24%) produced by Schizochytrium fermentation with KOH-ethanol solution. Heated to reflux in a water bath at 70°C for 0.5h. Cool to room temperature under the condition of nitrogen filling, after standing for stratification, take the fatty acid ethyl ester in the upper layer, distill and recover ethanol under reduced pressure at 60°C and -0.1Mpa, wash with warm water at 40°C repeatedly until the washing water is neutral, and separate the oil and water , the oil phase passes through anhydrous Na 2 SO 4 Filter and dry to obtain 474.8 g of ethyl-esterified DHA oil.

[0044] (2) Urea embedding - primary separation of gradient freeze crystallization: Prepare a urea ethanol solution with a mass fraction of 20%, and heat and reflux in a water bath at 65°C until the urea is completely dissolved. Mix the ethyl-esterified DHA oil and 20% urea-ethanol soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com