Desorption and regeneration method for organic matter adsorbent

A technology of adsorbent and organic matter, which is applied in the field of regeneration of organic pollutant adsorbent, can solve the problems of slow heat transfer rate, difficult storage and separation, and low dielectric constant, so as to reduce high-temperature hot spots and sparks, omit unit operation, Effect of reducing separation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

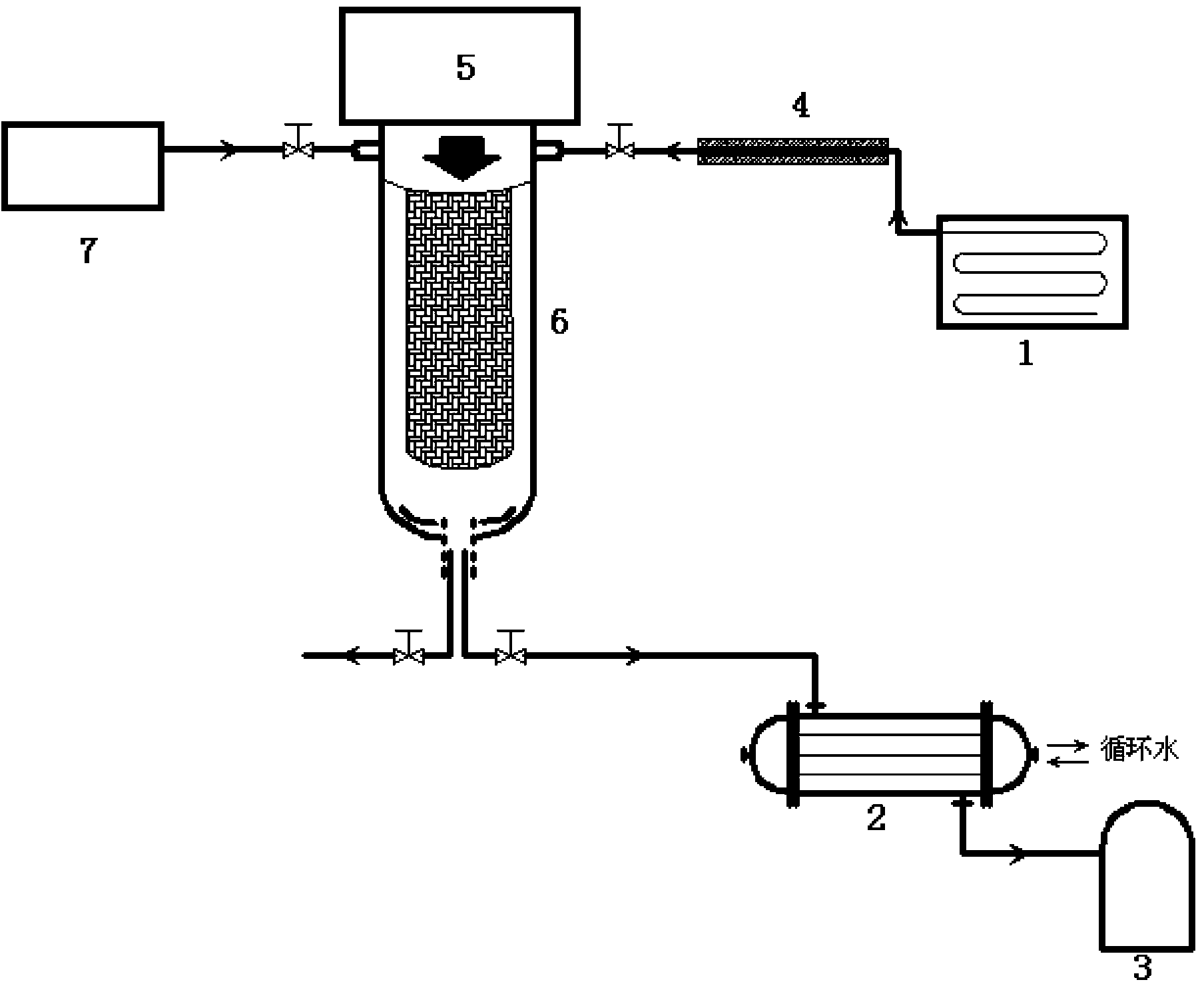

[0025] Get 2 grams of activated carbon fibers, absorb 2 grams of toluene, and pack into a desorption tower, such as figure 1 to build a desorption device. The desorption tower 6 is provided with a microwave generator 5, and the steam generator 1 is communicated with the steam inlet at the top of the desorption tower 6 through a flow meter, and the nitrogen generator 7 is communicated with the nitrogen inlet at the top of the desorption tower 6 through a flow meter, and the nitrogen gas The outlet and the steam outlet are respectively arranged at the bottom of the desorption tower 6, the steam outlet is connected to the condenser 2, and the outlet of the condenser 2 is connected to a storage container 3 for storing liquid organic matter and water condensed from the condenser. The pipeline between the steam generator 1 and the steam inlet at the top of the desorption tower 6 is provided with an insulation jacket 4 to prevent steam from condensing.

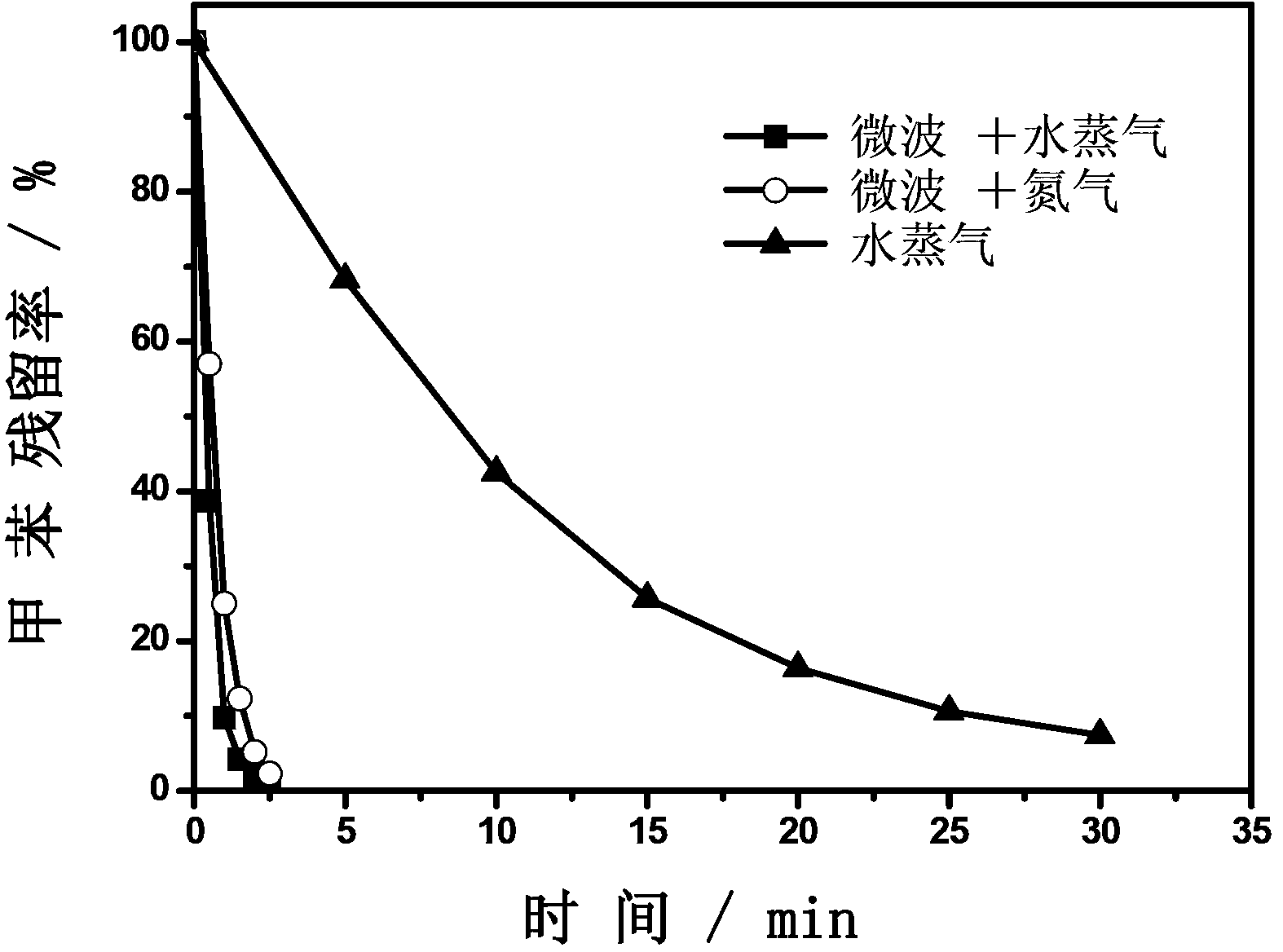

[0026] Desorption is perform...

Embodiment 2

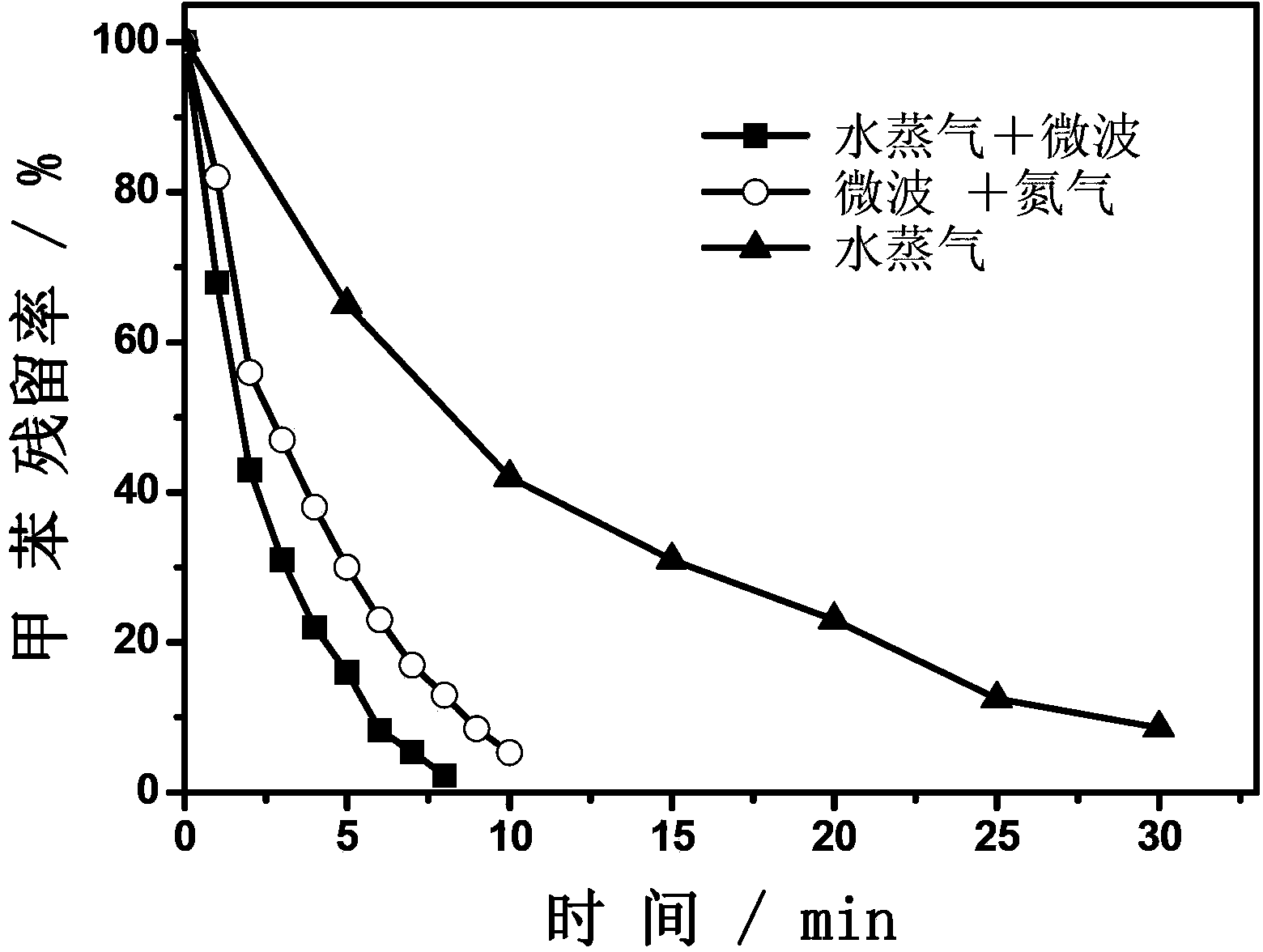

[0032]Take 2 grams of Y-type molecular sieves, absorb 2 grams of toluene, put them into a microwave desorption tower, and perform desorption according to the three methods of Example 1: (1) Microwave + water vapor, microwave power is 600W, water vapor flow rate is 1.0g / min; (3) microwave + nitrogen, nitrogen air velocity 2000h -1 ; (2) Water vapor, water vapor flow rate 1.0g / min.

[0033] The desorption rate comparison results of the above three methods are shown in image 3 , the results show that under the action of microwave, toluene on the surface of Y molecular sieve can be completely desorbed within 10 minutes. Under the synergistic effect of water vapor and microwave, the desorption rate is faster than single microwave, and the desorption can be completed within 7 minutes. However, it takes nearly 30 minutes to desorb completely by using a single water vapor desorption. Therefore, for Y molecular sieve adsorbents with a certain polarity, microwave can significantly ...

Embodiment 3

[0035] Take 2 grams of porous polymer resin polydivinylbenzene (PDVB), absorb 10 grams of toluene, put it into a microwave desorption tower, and perform desorption according to the three methods of Example 1: (1) microwave + water vapor, microwave power is 600W, water vapor flow rate 1.0g / min; (3) microwave + nitrogen, nitrogen air velocity 2000h -1 ; (2) Water vapor, water vapor flow rate 1.0g / min.

[0036] The desorption rate comparison results of the above three methods are shown in Figure 4 , found that under the action of a single microwave, the desorption rate of toluene on the resin surface was very slow, and after 30 minutes, the desorption rate only reached 40%. However, under the synergistic effect of water vapor and microwave, the desorption rate is greatly improved compared with single microwave, and the desorption can be completed within 5 minutes. However, it takes nearly 30 minutes to desorb completely by using a single water vapor desorption. Therefore, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com