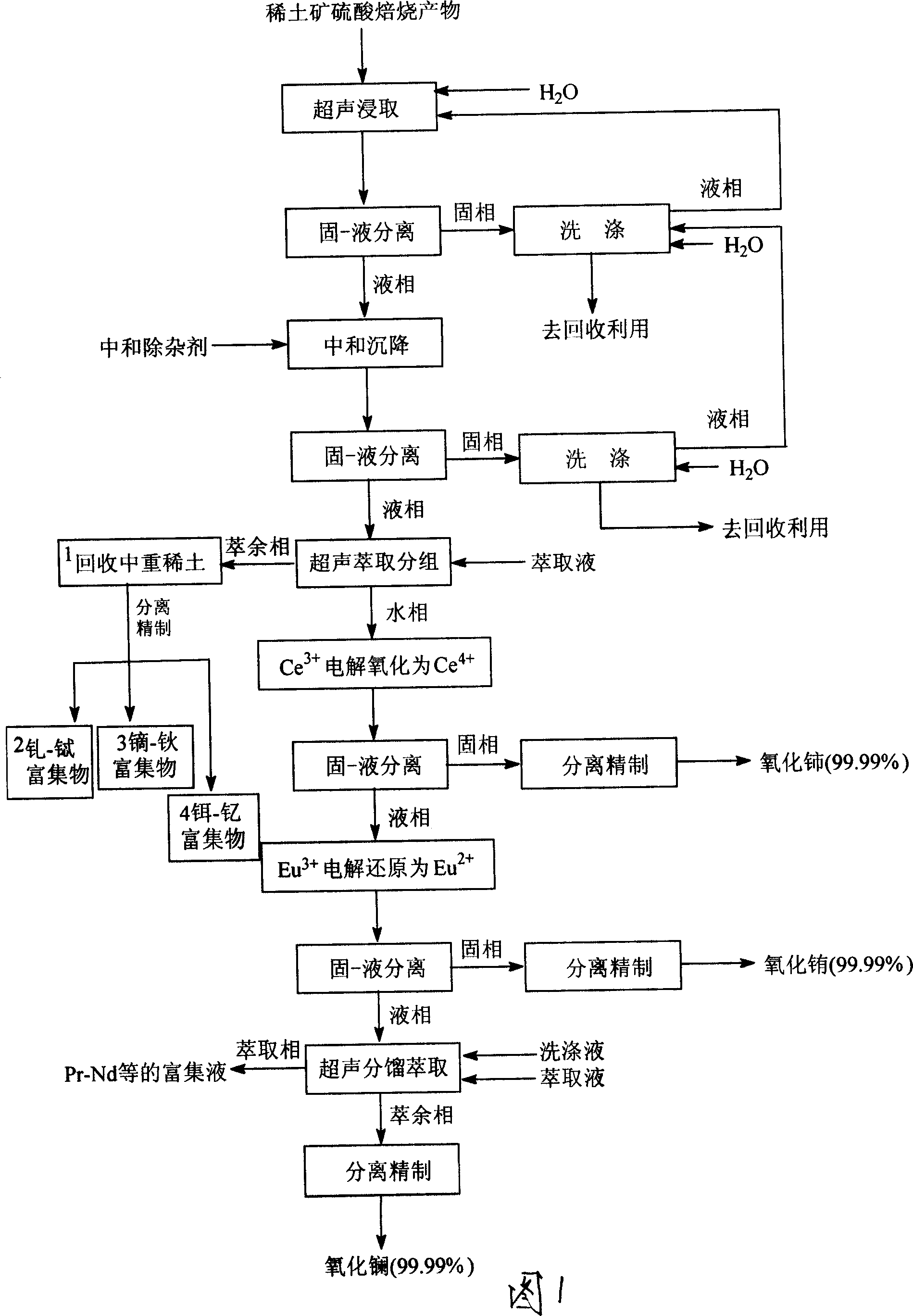

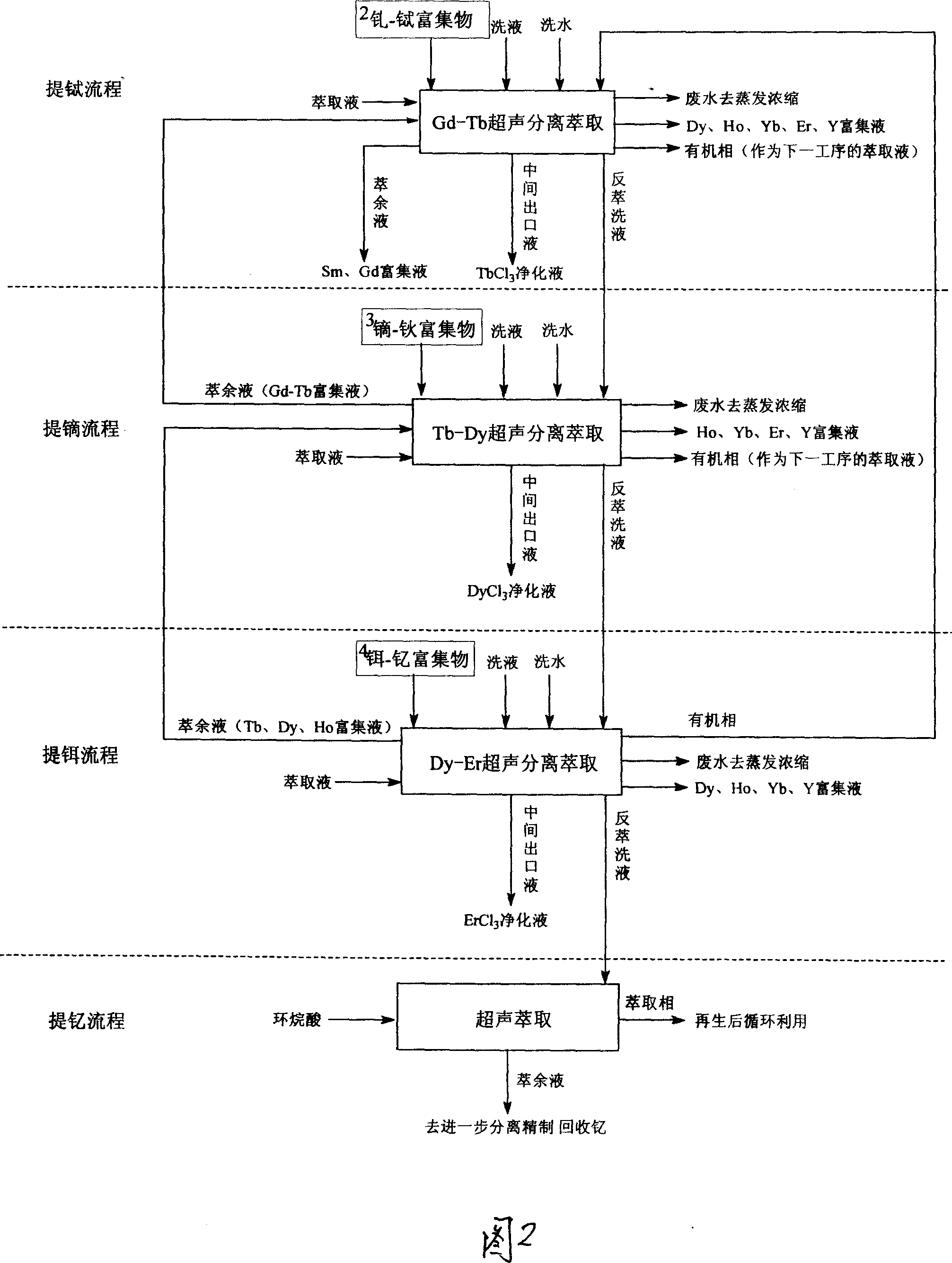

Method for separating highly-pure rare-earth oxide from sulphating roasting rare earth mine

A rare earth oxide and rare earth ore technology, applied in the field of hydrometallurgy, can solve the problems of large equipment loss, difficult stripping, complicated operation, etc., achieve the effect of reducing the amount of slag, improving the recovery rate, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Main production equipment: stirring batching mixing tank, ultrasonic leaching equipment, ultrasonic extraction equipment, ionic membrane electrochemical reactor, stirring neutralization precipitation tank, ultrasonic crystallization tank, filtration solid-liquid separation device, pure water and pure acid equipment and analysis and testing Instruments etc.

[0064] Main raw materials: sulfuric acid, hydrochloric acid, liquid ammonia, ammonium bicarbonate, ammonium carbonate, P204 extraction agent, P507 extraction agent, sulfuric acid intensified roasting method to smelt rare earth ores.

[0065] The process steps are as follows:

[0066] (1) Ultrasonic leaching: In a 1L stirred tank, add water, weigh 45g of the concentrated sulfuric acid roasting material of rare earth ore (the content of mixed rare earth oxide is greater than 30%), and add it to the ultrasonic leaching device, using an ultrasonic frequency of 19.8kHz, 250W For the probe-type ultrasonic generator, add ...

Embodiment 2

[0081] The purified rare earth sulfuric acid solution is used as the feed liquid for the fractional distillation extraction of neodymium-samarium, the concentration of the rare earth is 45.38g / L, the acidity of the feed liquid is 0.06mol / L sulfuric acid, and the organic phase has a P204 content of 1.0mol / L No. 260 solvent oil solvent, the acidity of the lotion is 0.572mol / L sulfuric acid, 4 stages of extraction section, 7 stages of washing section, 11 stages in total, and the flow ratio of organic phase, feed liquid and lotion is 15 milliliters: 66 milliliters: 5.5 milliliters, the contact time between the organic phase and the aqueous phase is 6 minutes, the extraction temperature is 27°C, and the percentage of each rare earth element in the feed liquid is La 2 o 3 27.53, CeO 2 49.70, Pr 6 o 11 5.13, Nd 2 o 3 15.44, Sm 2 o 3 1.20, Eu 2 o 3 0.23, Gd 2 o 3 0.33,Y 2 o 3 0.20. The aqueous phase discharged from the outlet of the first-stage aqueous phase in th...

Embodiment 3

[0084] Its experimental condition is basically the same as embodiment 4, and the difference is that the concentration of rare earth in the feed liquid is 30.17g / L rare earth oxide, and the acidity of feed liquid is 0.05mol / L sulfuric acid; The flow ratio of organic phase, feed liquid and washing liquid is 15 ml: 99 ml: 5.5 ml, the extraction temperature was 23°C. The rare earth concentration in the aqueous phase discharged from the organic phase outlet was 27.89g / L rare earth oxide. The concentration of its free acid is 0.089mol / L sulfuric acid, and the rare earth concentration in the discharged organic phase from the organic phase is 3.92g / L rare earth oxide. The composition in the organic phase is Nd 2 o 3 2 o 3 51.23%, Eu 2 o 3 11.55%, the composition of the aqueous phase La 2 o 3 28.21%, CeO 2 50.80%, Pr 6 o 11 5.23%, Nd 2 o 3 16.35%, Sm 2 o 3 2 o 3The recovery rate of 100.12%, Nd 2 o 3 The recovery rate was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com