Isolating plate structure for continuous casting of molten steel

A separation plate and molten steel technology, applied in the field of metallurgy, can solve the problems of reducing the amount of reaction between strong reducing elements and mold slag, and achieve the effects of reducing the amount of inclusions, reducing cracks in casting slabs, and reducing the loss of alloy elements in molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

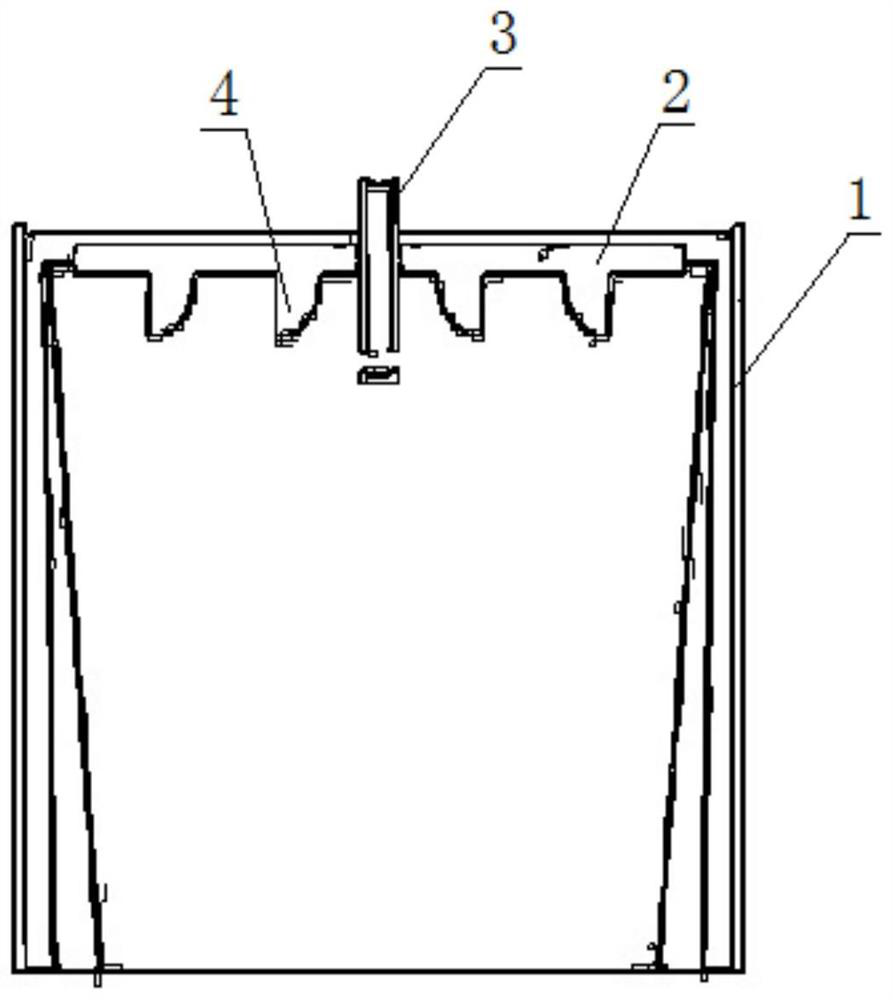

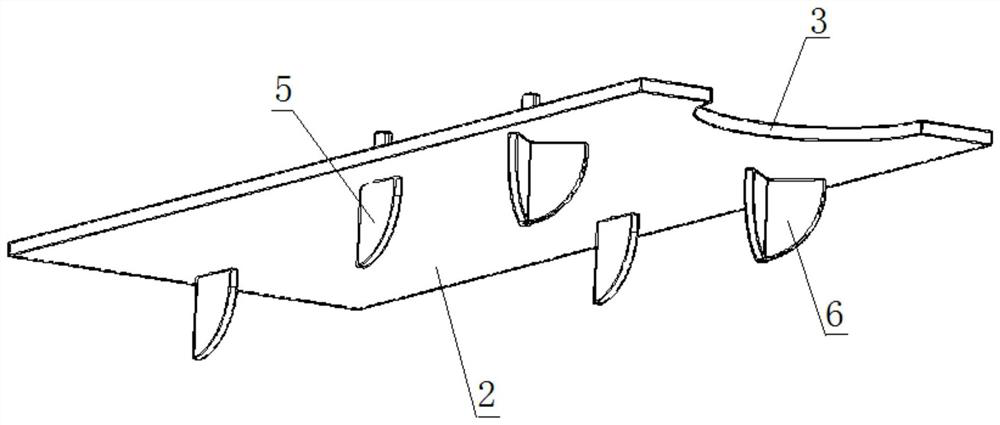

[0029] like figure 1 and figure 2 As shown, the present invention is a molten steel continuous casting isolation plate structure, including a crystallizer 1, and an isolation plate 2 is placed horizontally in the crystallizer 1. The isolation plate 2 is not eroded by mold slag and does not react with active ingredients in molten steel. The density of plate 2 is greater than the density of liquid mold slag and smaller than the density of molten steel. The isolation plate 2 is stabilized in the crystallizer 1 through several brackets installed on the continuous casting machine, and the size of the isolation plate 2 is smaller than the cross-sectional size of the mold 1. The isolation plate There is a gap between 2 and the wall of crystallizer 1.

[0030]Among them, the middle part of the isolation plate 2 has a hole 3 for the submerg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com