Method for continuously predicting carbon content of converter molten pool

A carbon content and molten pool technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of specifying the control process, specifying the control of raw materials, etc., to achieve stable furnace gas flow and composition, Ensure stable and reliable effects of molten steel composition and information

Active Publication Date: 2010-09-15

ANGANG STEEL CO LTD

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above methods are all focused on the research of detection means, relying too much on the mathematical model calculated by using the detection data, and the literature materials that have been found have not made regulations on raw material control, such as the type and proportion of scrap steel, nor on the process. Explain the control process, such as the control of the gun position and the amount of oxygen blowing, and these are important factors affecting the carbon hit at the end point. The mathematical model must be combined with the actual process control to play its due role

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

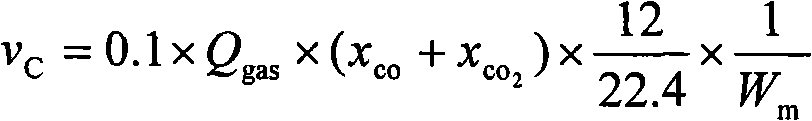

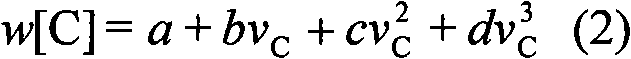

The invention discloses a method for continuously predicting carbon content of a converter molten pool, which comprises data acquisition, raw material control, operation control and technical process and specifically comprises the following steps of: in the data acquisition, detecting converter gas flow by using a converter gas flow meter, transmitting all detection information to a computer through a data communication system, and analyzing and calculating the detection information through the following two mathematical models w[C]=0.1*(sigma Cori-sigma Cde) / Wm (1); in the raw material control, controlling a waste steel ratio to be 8 to 13 percent, and controlling the weight percentage of light waste steel and heavy waste steel to be 14 to 70 percent; in the operation control, holding a fixed gun position and a fixed smoke hood in 2 to 3 minutes before finishing blowing; and in the technical process, ensuring that the carbon content of the molten pool meets the formula (1) when the oxygen blowing amount accounts for less than or equal to 75 percent of the total oxygen blowing amount and the carbon content of the molten pool meets the formula (2) when the oxygen blowing amount accounts for over 75 percent of the total oxygen blowing amount. The method fulfills the purpose of continuously predicting the carbon content of the converter molten pool by combining the mathematical models and the technical process.

Description

technical field The invention relates to a processing method for predicting carbon content in a steelmaking process, in particular to a method for continuously predicting carbon content in a melting pool during a converter smelting process. Background technique Two methods, static model control and dynamic model control, are commonly used in the control process of converter steelmaking. No matter what kind of control method it is, it needs accurate raw furnace data and process inspection data. Among them, the raw data of the furnace is determined by the specific actual conditions of each steelmaking plant, and it is difficult to achieve substantial improvement and change within a certain period of time. important. One of the key tasks of converter steelmaking is carbon determination. How to obtain the change of the carbon content of the melt pool during the blowing process quickly, accurately and at low cost has great practical significance and economic value. In the pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/64

Inventor 万雪峰李德刚廖相巍李镇曹东赵刚贾吉祥王鹏王丽娟徐咏梅

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com