Multielement material collaborative gasification method and system

A gasification system and material technology, applied in the field of resource utilization of waste, can solve the problems of inability to utilize organic fluid waste, increase investment, consume large energy consumption, etc., achieve the combination of high and low energy levels, and avoid disposal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

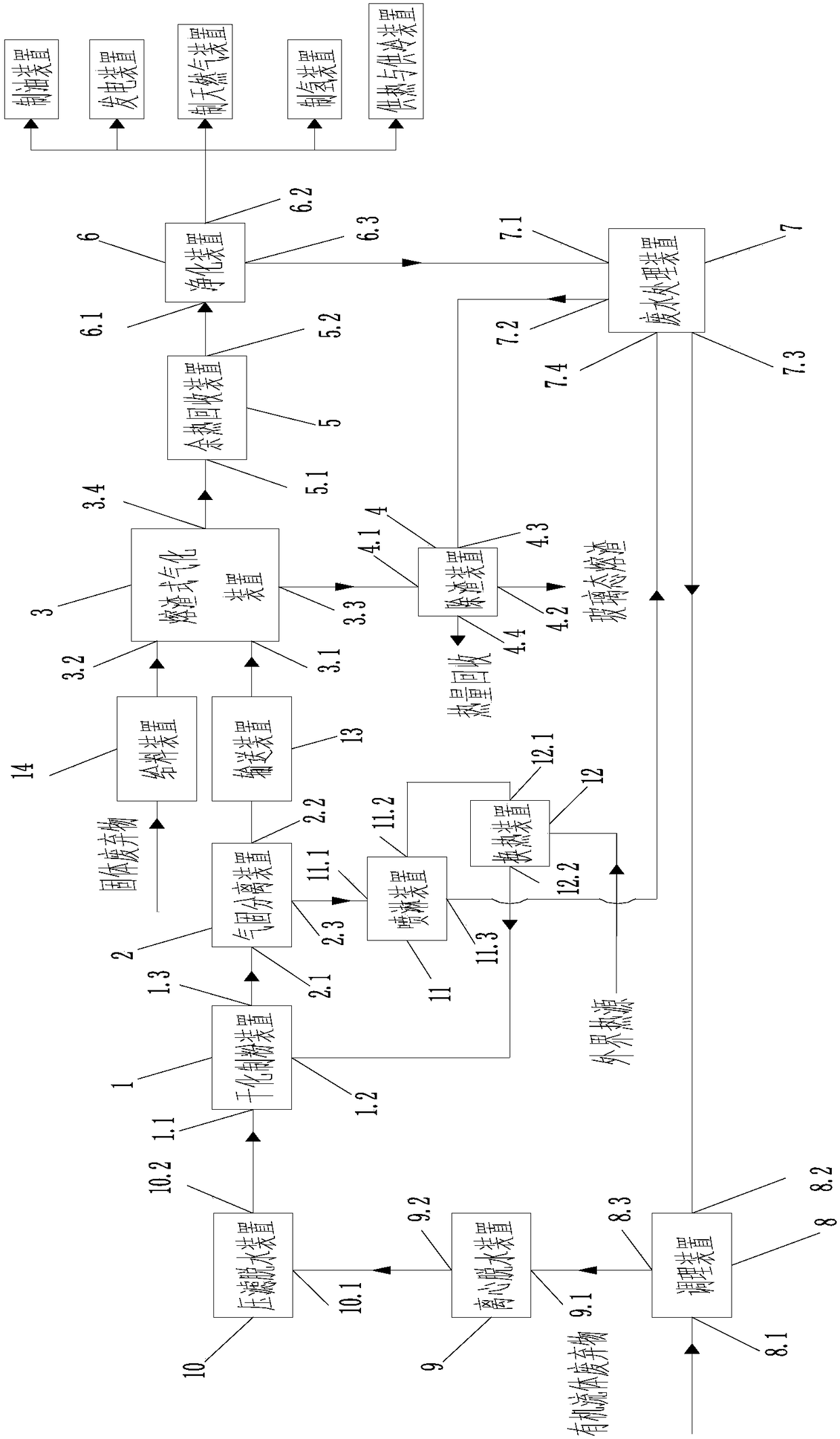

[0057] like figure 1 Shown is the multi-material collaborative gasification system of the first embodiment, including a dry pulverization device 1, a gas-solid separation device 2, a slag-type gasification device 3, a slag removal device 4, a waste heat recovery device 5, and a purification device 6. Wastewater treatment device 7 , conditioning device 8 , centrifugal dehydration device 9 , filter press dehydration device 10 , spray device 11 , and heat exchange device 12 . In this embodiment, the gas-solid separation device 2 is preferably a cyclone separator; the slag gasification device 3 is preferably a fixed bed slag gasifier, a fluidized bed slag gasifier, or a plasma slag gasifier. One; the slag removal device 4 is preferably a slag removal tank; the waste heat recovery device 5 is preferably a waste heat recovery boiler; the purification device 6 is preferably a purification tower; the conditioning device 8 is preferably a conditioning tank; the centrifugal dehydration ...

Embodiment 2

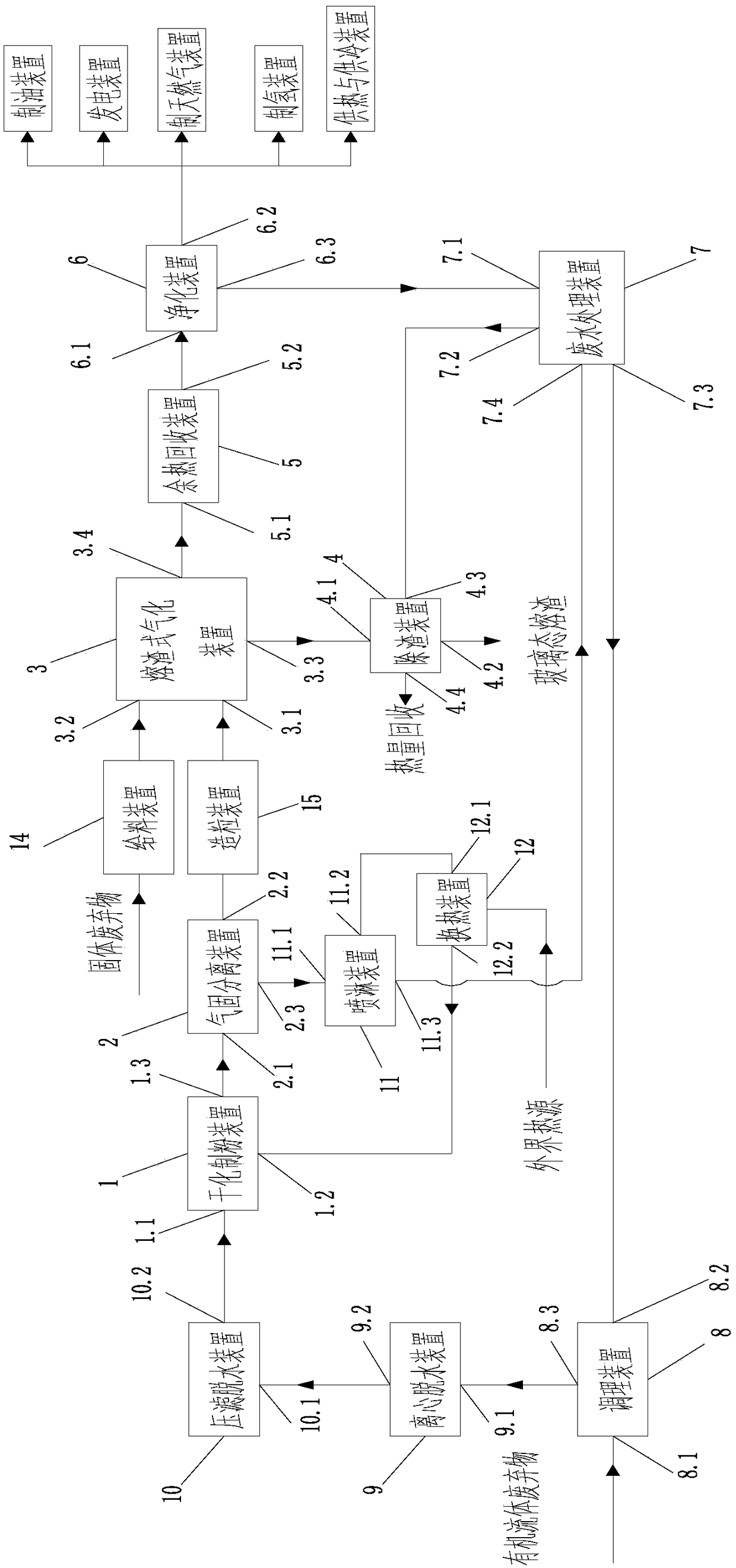

[0071] like image 3 Shown is the multi-component material collaborative gasification system of the second embodiment, including dry pulverization device 1, gas-solid separation device 2, slag-type gasification device 3, slag removal device 4, waste heat recovery device 5, and purification device 6. Wastewater treatment device 7 , conditioning device 8 , centrifugal dehydration device 9 , filter press dehydration device 10 , spray device 11 , and heat exchange device 12 . In this embodiment, the gas-solid separation device 2 is preferably a cyclone separator; the slag gasification device 3 is preferably a fixed bed slag gasifier, a fluidized bed slag gasifier, or a plasma slag gasifier. One; the slag removal device 4 is preferably a slag removal tank; the waste heat recovery device 5 is preferably a waste heat recovery boiler; the purification device 6 is preferably a purification tower; the conditioning device 8 is preferably a conditioning tank; the centrifugal dehydration d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com