X fluorescence determination method for potassium nitrate ashigh-aluminum glass raw material

A high-alumina glass, fluorescence measurement technology, applied in the analysis of materials, material analysis using wave/particle radiation, measuring devices, etc., can solve the difficulty in meeting the requirements of analysis accuracy, environmental pollution of waste liquid in analysis experiments, and cumbersome analysis steps and other problems, to achieve the effect of sample uniformity, improve analysis efficiency, and simple sample processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

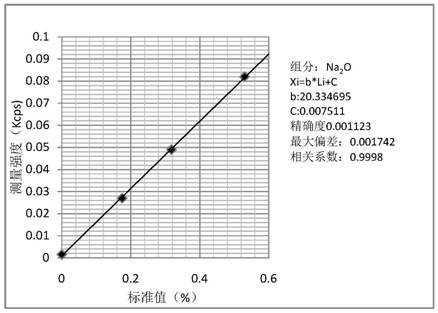

[0043] Step 1: adopt commercially available potassium nitrate purity standard sample to add commercially available sodium chloride standard substance preparation standard sample, prepare respectively 100g standard series sample 1#, 2#, 3#, 4#, the preparation parameter of described standard sample See Table 1 for the table;

[0044] The standard sample series preparation parameter table of table 1 embodiment 1

[0045]

[0046]

[0047] Step 2: Mix lithium tetraborate and metaboric acid evenly at a mass ratio of 1:1 and use it as a mixed co-solvent;

[0048] Step 3: Weigh 0.4g of the standard sample 1# in the above step 1, and weigh 8g of the mixed co-solvent in the step 2, place them in a petri dish, stir evenly, and form a mixed sample, a total of 8.4g mixed samples;

[0049] Step 4: Transfer the mixed sample of the petri dish in step 3 to a platinum yellow crucible, and drop 1 drop of release agent NH on its surface 4 Br aqueous solution;

[0050] Step 5: Place the...

Embodiment 2

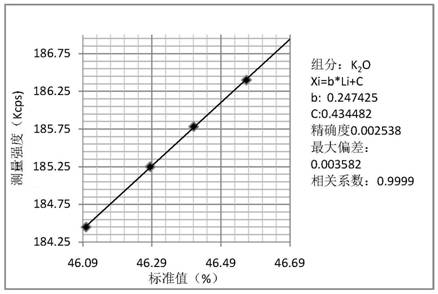

[0064] Step 1: adopt commercially available potassium nitrate purity standard sample to add commercially available sodium chloride standard substance preparation standard sample, prepare respectively 100g standard series sample 1#, 2#, 3#, 4#, the preparation parameter of described standard sample See Table 5;

[0065] The standard sample series preparation parameter table of table 5 embodiment 2

[0066]

[0067]

[0068] Step 2: Mix lithium tetraborate and metaboric acid evenly in a mass ratio of 2:1 as a mixed co-solvent;

[0069] Step 3: Weigh 0.6g of the standard sample 1# in the above step 1, and weigh 9g of the mixed co-solvent in the step 2, place them in a petri dish, stir evenly, and form a mixed sample, a total of 9.6g mixed samples;

[0070] Step 4: Transfer the mixed sample of the petri dish in step 3 to a platinum yellow crucible, and drop 3 drops of release agent NH on its surface 4 I aqueous solution;

[0071] Step 5: Place the platinum yellow crucible...

Embodiment 3

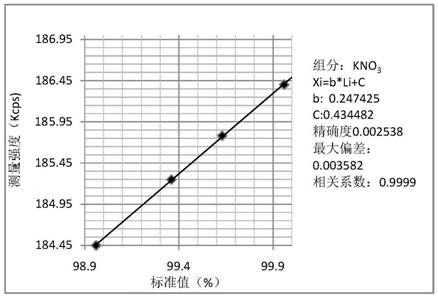

[0086] Step 1: adopt commercially available potassium nitrate purity standard sample to add commercially available sodium chloride standard substance preparation standard sample, prepare respectively 100g standard series sample 1#, 2#, 3#, 4#, the preparation parameter of described standard sample See Table 1 for the table;

[0087] The standard sample series preparation parameter table of table 9 embodiment 3

[0088]

[0089] Step 2: Mix lithium tetraborate and metaboric acid evenly at a mass ratio of 1.5:1 as a mixed co-solvent;

[0090] Step 3: Weigh 0.5g of the standard sample 1# in the above step 1, and weigh 8.5g of the mixed co-solvent in the step 2, place them in a petri dish, stir evenly, and form a mixed sample, a total of 9g mixed samples;

[0091] Step 4: Transfer the mixed sample of the petri dish in step 3 to a platinum yellow crucible, and drop 2 drops of release agent NH on its surface 4 I aqueous solution;

[0092] Step 5: Place the platinum yellow cruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com