Pouring molten iron and smelting process of natural gas powered cylinder

A power cylinder and natural gas technology, which is applied in the field of pouring molten iron for natural gas power cylinders and its smelting process, can solve problems such as poor mechanical properties, low casting strength, and unsatisfactory performance, and achieve the goals of improving quality, meeting demands, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

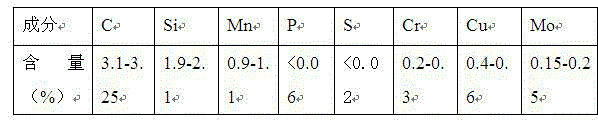

Method used

Image

Examples

Embodiment 1

[0079] The smelting process of pouring molten iron into the natural gas-powered cylinder body of the present embodiment comprises the following steps:

[0080] (1) Prepare raw materials in the following parts by weight: 1250 parts of Q12 Benxi pig iron, 250 parts of steel scrap, 700 parts of returned iron, 4 parts of ferrochromium, 6 parts of ferromolybdenum, 9 parts of copper, and 9 parts of ferrosilicon;

[0081] (2) First add ferromolybdenum and soldering iron to the furnace bottom of the smelting vessel, and then add Q12 Benxi pig iron, scrap steel, returned iron and ferrosilicon for melting;

[0082] (3) After the charge in the smelting container is completely melted, the temperature is raised to 1310°C and the slag is removed;

[0083] (4) Pre-stove inspection and composition adjustment;

[0084] (5) Add copper when the temperature rises to 1310°C; continue to heat up to 1450°C, and prepare to be released when the temperature is 1430°C.

[0085] (6) The molten iron in ...

Embodiment 2

[0091] The smelting process of pouring molten iron into the natural gas-powered cylinder body of the present embodiment comprises the following steps:

[0092] (1) Prepare raw materials in the following parts by weight: 1250 parts of Q12 Benxi pig iron, 250 parts of steel scrap, 700 parts of returned iron, 4 parts of ferrochromium, 6 parts of ferromolybdenum, 9 parts of copper, and 9 parts of ferrosilicon;

[0093] (2) First add ferromolybdenum and soldering iron to the furnace bottom of the smelting vessel, and then add Q12 Benxi pig iron, scrap steel, returned iron and ferrosilicon for melting;

[0094] (3) After the charge in the smelting container is completely melted, the temperature is raised to 1390°C and the slag is removed;

[0095] (4) Pre-stove inspection and composition adjustment;

[0096] (5) Add copper when the temperature rises to 1390°C; continue to heat up to 1460°C and keep warm for 5 minutes before being ready to be released from the furnace;

[0097] (6)...

Embodiment 3

[0103] The smelting process of pouring molten iron into the natural gas-powered cylinder body of the present embodiment comprises the following steps:

[0104] (1) Prepare raw materials in the following parts by weight: 1250 parts of Q12 Benxi pig iron, 250 parts of steel scrap, 700 parts of returned iron, 4 parts of ferrochromium, 6 parts of ferromolybdenum, 9 parts of copper, and 9 parts of ferrosilicon;

[0105] (2) First add ferromolybdenum and soldering iron to the furnace bottom of the smelting vessel, and then add Q12 Benxi pig iron, scrap steel, returned iron and ferrosilicon for melting;

[0106] (3) After the charge in the smelting container is completely melted, the temperature is raised to 1320°C and the slag is removed;

[0107] (4) Pre-stove inspection and composition adjustment;

[0108] (5) Add copper when the temperature rises to 1320°C; continue to heat up to 1450°C and then keep it for 10 minutes, and then prepare to be released when the temperature is 1430...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com